Diploma Thesis - Erich Schmid Institute

Diploma Thesis - Erich Schmid Institute

Diploma Thesis - Erich Schmid Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8. Deposition of Thin Films<br />

Deposition of Thin Films<br />

8.1. Magnetron sputtering of polycrystalline Al thin films on Si(1 0 0)<br />

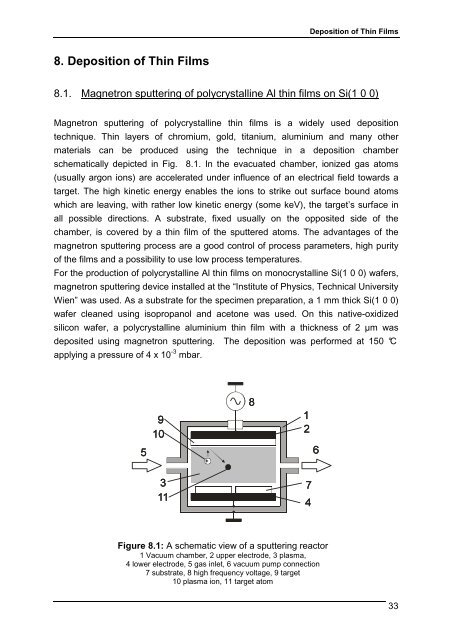

Magnetron sputtering of polycrystalline thin films is a widely used deposition<br />

technique. Thin layers of chromium, gold, titanium, aluminium and many other<br />

materials can be produced using the technique in a deposition chamber<br />

schematically depicted in Fig. 8.1. In the evacuated chamber, ionized gas atoms<br />

(usually argon ions) are accelerated under influence of an electrical field towards a<br />

target. The high kinetic energy enables the ions to strike out surface bound atoms<br />

which are leaving, with rather low kinetic energy (some keV), the target’s surface in<br />

all possible directions. A substrate, fixed usually on the opposited side of the<br />

chamber, is covered by a thin film of the sputtered atoms. The advantages of the<br />

magnetron sputtering process are a good control of process parameters, high purity<br />

of the films and a possibility to use low process temperatures.<br />

For the production of polycrystalline Al thin films on monocrystalline Si(1 0 0) wafers,<br />

magnetron sputtering device installed at the “<strong>Institute</strong> of Physics, Technical University<br />

Wien” was used. As a substrate for the specimen preparation, a 1 mm thick Si(1 0 0)<br />

wafer cleaned using isopropanol and acetone was used. On this native-oxidized<br />

silicon wafer, a polycrystalline aluminium thin film with a thickness of 2 µm was<br />

deposited using magnetron sputtering. The deposition was performed at 150 °C<br />

applying a pressure of 4 x 10 -3 mbar.<br />

+<br />

Figure 8.1: A schematic view of a sputtering reactor<br />

1 Vacuum chamber, 2 upper electrode, 3 plasma,<br />

4 lower electrode, 5 gas inlet, 6 vacuum pump connection<br />

7 substrate, 8 high frequency voltage, 9 target<br />

10 plasma ion, 11 target atom<br />

33