Diploma Thesis - Erich Schmid Institute

Diploma Thesis - Erich Schmid Institute

Diploma Thesis - Erich Schmid Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

X-ray Diffraction – Measurements and Alignment<br />

so that the centre of the top face is in the middle of the laser spot. Afterwards the<br />

shade holder together with the laser is removed and the detector is turned back to<br />

0° position. Afterwards a dial gauge is mounted in fro nt of the diffractometer plate to<br />

adjust the height to 5,75 mm.<br />

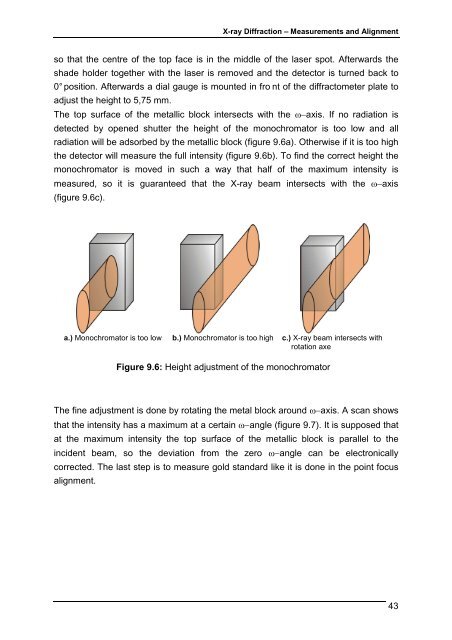

The top surface of the metallic block intersects with the ω−axis. If no radiation is<br />

detected by opened shutter the height of the monochromator is too low and all<br />

radiation will be adsorbed by the metallic block (figure 9.6a). Otherwise if it is too high<br />

the detector will measure the full intensity (figure 9.6b). To find the correct height the<br />

monochromator is moved in such a way that half of the maximum intensity is<br />

measured, so it is guaranteed that the X-ray beam intersects with the ω−axis<br />

(figure 9.6c).<br />

a.) Monochromator is too low b.) Monochromator is too high c.) X-ray beam intersects with<br />

rotation axe<br />

The fine adjustment is done by rotating the metal block around ω−axis. A scan shows<br />

that the intensity has a maximum at a certain ω−angle (figure 9.7). It is supposed that<br />

at the maximum intensity the top surface of the metallic block is parallel to the<br />

incident beam, so the deviation from the zero ω−angle can be electronically<br />

corrected. The last step is to measure gold standard like it is done in the point focus<br />

alignment.<br />

Figure 9.6: Height adjustment of the monochromator<br />

43