AN-8027 — FAN480X PFC+PWM Combination Controller Application

AN-8027 — FAN480X PFC+PWM Combination Controller Application

AN-8027 — FAN480X PFC+PWM Combination Controller Application

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>AN</strong>-<strong>8027</strong><br />

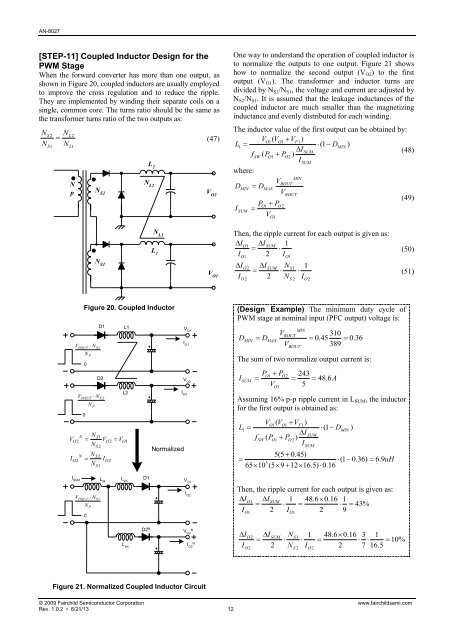

[STEP-11] Coupled Inductor Design for the<br />

PWM Stage<br />

When the forward converter has more than one output, as<br />

shown in Figure 20, coupled inductors are usually employed<br />

to improve the cross regulation and to reduce the ripple.<br />

They are implemented by winding their separate coils on a<br />

single, common core. The turns ratio should be the same as<br />

the transformer turns ratio of the two outputs as:<br />

NS 2 NL<br />

2<br />

(47)<br />

N N<br />

S1 L1<br />

N<br />

p<br />

N S2<br />

N S1<br />

L 2<br />

N L2<br />

N L1<br />

L 1<br />

Figure 20. Coupled Inductor<br />

V N<br />

N<br />

POUT S1<br />

0<br />

0<br />

P<br />

V N<br />

N<br />

POUT S 2<br />

0<br />

P<br />

V N<br />

N<br />

D1<br />

D2<br />

N<br />

V V V<br />

POUT S1<br />

P<br />

L M<br />

L1<br />

L2<br />

N S1<br />

O2 O2 O1<br />

NS<br />

2<br />

N<br />

I I<br />

N S 2<br />

O2 O2<br />

NS1<br />

I SUM<br />

L LK<br />

L LK<br />

D1<br />

D2 N<br />

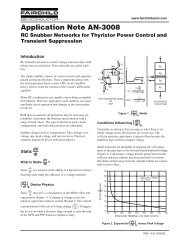

Normalized<br />

V O1<br />

I O1<br />

V O2<br />

I O2<br />

V O1<br />

I O2<br />

V N<br />

O2<br />

N IO2 Figure 21. Normalized Coupled Inductor Circuit<br />

VO2<br />

V O1<br />

One way to understand the operation of coupled inductor is<br />

to normalize the outputs to one output. Figure 21 shows<br />

how to normalize the second output (VO2) to the first<br />

output (VO1). The transformer and inductor turns are<br />

divided by NS2/NS1, the voltage and current are adjusted by<br />

NS2/NS1. It is assumed that the leakage inductances of the<br />

coupled inductor are much smaller than the magnetizing<br />

inductance and evenly distributed for each winding.<br />

The inductor value of the first output can be obtained by:<br />

L1 VO1( VO1 VF<br />

1)<br />

ISUM<br />

fSW ( PO 1PO2) ISUM<br />

(1 DMIN)<br />

(48)<br />

where:<br />

MIN<br />

VBOUT<br />

DMINDMAX VBOUT<br />

PO1PO2 ISUM<br />

<br />

V<br />

(49)<br />

© 2009 Fairchild Semiconductor Corporation www.fairchildsemi.com<br />

Rev. 1.0.2 • 6/21/13 12<br />

O1<br />

Then, the ripple current for each output is given as:<br />

IO1ISUM1 <br />

I 2 I<br />

(50)<br />

O1 O1<br />

IO2 ISUMNS1<br />

1<br />

(51)<br />

I 2 N I<br />

O2 S 2 O2<br />

(Design Example) The minimum duty cycle of<br />

PWM stage at nominal input (PFC output) voltage is:<br />

MIN<br />

VBOUT<br />

310<br />

DMINDMAX 0.45 0.36<br />

V<br />

389<br />

BOUT<br />

The sum of two normalize output current is:<br />

P P<br />

243<br />

O1 O2<br />

ISUM 48.6A<br />

VO1<br />

5<br />

Assuming 16% p-p ripple current in LSUM, the inductor<br />

for the first output is obtained as:<br />

V ( V V<br />

)<br />

O1 O1 F1<br />

L1DMIN ISUM<br />

fSW ( PO 1PO2) ISUM<br />

3<br />

6510 (5 9 12 16.5) 0.16<br />

(1 )<br />

5(5 0.45)<br />

(1 0.36) 6.9uH<br />

Then, the ripple current for each output is given as:<br />

IO1ISUM148.60.161 43%<br />

I 2 I 2 9<br />

O1 O1<br />

IO2 ISUMNS1 1 48.6 0.16 3 1<br />

<br />

10%<br />

I 2 N I 2 7 16.5<br />

O2 S 2 O2