SS-3 - Gaugemaster.com

SS-3 - Gaugemaster.com

SS-3 - Gaugemaster.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GAUGEMASTER ®<br />

MODEL <strong>SS</strong>-3 AUTOMATIC OPERATING SYSTEM<br />

This unit is designed to allow two lo<strong>com</strong>otives to be run on one circuit of track yet not collide with one another due to different<br />

running speeds. This is ac<strong>com</strong>plished by dividing the track into five sections and connecting the unit in line between these and a<br />

controlled output. The system is then monitored by reed switches installed under the track at various points which are triggered by<br />

magnets under the lo<strong>com</strong>otives. The two lo<strong>com</strong>otives can then be run simultaneously, each only being able to proceed onto the<br />

following section when it is safe to do so. A soft start and stop have been incorporated to enhance the operation.<br />

There is also an optional facility to install two aspect colour light signals at each section.<br />

Bypass switches can also be added to allow lo<strong>com</strong>otives to be reversed in and out of sidings if desired.<br />

INSTALLATION<br />

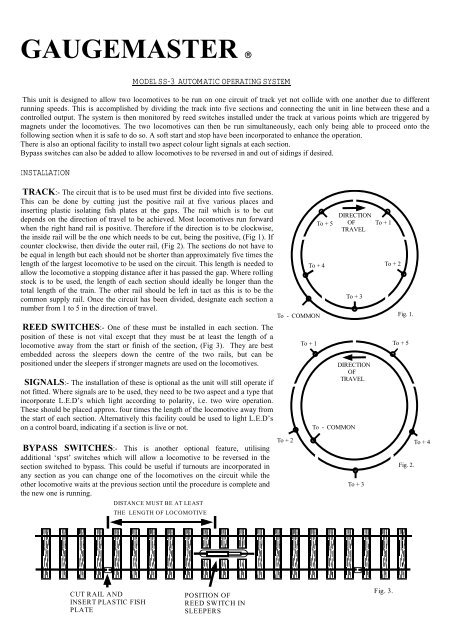

TRACK:- The circuit that is to be used must first be divided into five sections.<br />

This can be done by cutting just the positive rail at five various places and<br />

inserting plastic isolating fish plates at the gaps. The rail which is to be cut<br />

depends on the direction of travel to be achieved. Most lo<strong>com</strong>otives run forward<br />

when the right hand rail is positive. Therefore if the direction is to be clockwise,<br />

the inside rail will be the one which needs to be cut, being the positive, (Fig 1). If<br />

counter clockwise, then divide the outer rail, (Fig 2). The sections do not have to<br />

be equal in length but each should not be shorter than approximately five times the<br />

length of the largest lo<strong>com</strong>otive to be used on the circuit. This length is needed to<br />

allow the lo<strong>com</strong>otive a stopping distance after it has passed the gap. Where rolling<br />

stock is to be used, the length of each section should ideally be longer than the<br />

total length of the train. The other rail should be left in tact as this is to be the<br />

<strong>com</strong>mon supply rail. Once the circuit has been divided, designate each section a<br />

number from 1 to 5 in the direction of travel.<br />

REED SWITCHES:- One of these must be installed in each section. The<br />

position of these is not vital except that they must be at least the length of a<br />

lo<strong>com</strong>otive away from the start or finish of the section, (Fig 3). They are best<br />

embedded across the sleepers down the centre of the two rails, but can be<br />

positioned under the sleepers if stronger magnets are used on the lo<strong>com</strong>otives.<br />

SIGNALS:- The installation of these is optional as the unit will still operate if<br />

not fitted. Where signals are to be used, they need to be two aspect and a type that<br />

incorporate L.E.D’s which light according to polarity, i.e. two wire operation.<br />

These should be placed approx. four times the length of the lo<strong>com</strong>otive away from<br />

the start of each section. Alternatively this facility could be used to light L.E.D’s<br />

on a control board, indicating if a section is live or not.<br />

BYPA<strong>SS</strong> SWITCHES:- This is another optional feature, utilising<br />

additional ‘spst’ switches which will allow a lo<strong>com</strong>otive to be reversed in the<br />

section switched to bypass. This could be useful if turnouts are incorporated in<br />

any section as you can change one of the lo<strong>com</strong>otives on the circuit while the<br />

other lo<strong>com</strong>otive waits at the previous section until the procedure is <strong>com</strong>plete and<br />

the new one is running.<br />

CUT RAIL AND<br />

INSERT PLASTIC FISH<br />

PLATE<br />

DISTANCE MUST BE AT LEAST<br />

THE LENGTH OF LOCOMOTIVE<br />

POSITION OF<br />

REED SWITCH IN<br />

SLEEPERS<br />

To + 4<br />

To - COMMON<br />

To + 1<br />

To + 5<br />

DIRECTION<br />

OF<br />

TRAVEL<br />

To + 3<br />

DIRECTION<br />

OF<br />

TRAVEL<br />

To - COMMON<br />

To + 2 To + 4<br />

To + 3<br />

To + 1<br />

To + 2<br />

Fig. 3.<br />

Fig. 1.<br />

To + 5<br />

Fig. 2.

CONNECTING THE UNIT<br />

TRACK:- There will be six wires in total, i.e. one <strong>com</strong>mon and one from each section. Connect the <strong>com</strong>mon rail to terminal<br />

marked as such and each section according to its designated section number on the unit.<br />

REED SWITCHES:- Connect one side of each switch to the unit according to its designated section number. Connect the<br />

remaining side of each switch together to form a <strong>com</strong>mon and connect to terminal marked as such on unit. If signals are being<br />

installed do not connect to unit at this stage. (See signal check)<br />

SIGNALS:- Connect each signal to the unit according to the designated section number.<br />

BYPA<strong>SS</strong> SWITCHES:- Only the sections to be bypassed need to be connected to an ‘on - off ’ switch.<br />

CONTROLLER:- Connect the two wires from the controllers controlled output to the unit where marked. ‘12v DC input’.<br />

Polarity can be changed by direction switch if this is connected the wrong way. If it is the wrong way the circuit will simply remain<br />

dead, unless bypass switches are used and turned on.<br />

Connect the two terminals marked ‘16v AC input’ to a constant supply of 16v AC.<br />

SIGNAL CHECK:- When the 16v AC is turned on at this stage, all the signals should be showing green. If any show red, the<br />

two wires for that signal must be reversed. When all are showing green, the <strong>com</strong>mon wire from the reed switches can be connected to<br />

terminal marked as such on the unit.<br />

PREPARING THE LOCOMOTIVES<br />

Each lo<strong>com</strong>otive to be run on the circuit needs a magnet to be installed somewhere under the chassis in a position that enables it to<br />

pass closely over each of the reed switches.<br />

RUNNING THE CIRCUIT<br />

First ensure the unit is reset. This is done by removing the power from the 16v AC for a moment. When this is done, the signals if<br />

used will show green. With the controller set at zero, place the two lo<strong>com</strong>otives on two different sections with a clear section in<br />

between them. Increase the power on the controller and both of the lo<strong>com</strong>otives will start moving. If they do not, change the direction<br />

switch to the opposite direction. The circuit is now operational and the lo<strong>com</strong>otives should continue running and never meet. This is<br />

achieved as the section behind each train is switched off until the next one on is clear. The lo<strong>com</strong>otives will stop and start as required.<br />

GUARANTEE:<br />

We undertake to replace, free of charge, any parts found defective within the lifetime of the unit, providing the item has not been<br />

tampered with and parts are still available for such a repair. This guarantee covers only the supply of replacement parts, labour cost<br />

for fitting of the same and the cost of returning the unit to the customer or retailer.<br />

This Guarantee does not affect your statutory Rights.<br />

We reserve the right to vary design or specification without notice.<br />

A CATALOGUE ON THE FULL RANGE OF GAUGEMASTER PRODUCTS IS AVAILABLE<br />

GAUGEMASTER CONTROLS PLC Ford Road, Arundel, West Sussex, BN18 OBN.<br />

Tel. No: 01903 884321 Fax.No: 01903 884373<br />

Registered in England. Reg.No: 2714470.