AerospaceIndustry - Frank Drucklufttechnik

AerospaceIndustry - Frank Drucklufttechnik

AerospaceIndustry - Frank Drucklufttechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Doler Self Colleting Machines Accessories Doler Self Colleting Machines Accessories<br />

PL Drill Point Lubricator 85-044<br />

The Drill Point Lubricator provides lubricated air to the point of<br />

the cutter. The Doler PL Lubricator is mounted on the Control<br />

Valve Module. The Drill Point Lubricator has a quick disconnect<br />

fitting for rapid no-mess refilling; use 80-503 Wall Tank to refill it<br />

or it can be filled manually and requires no additional<br />

equipment. Refer to page 17.<br />

Adjustable Foot Pad<br />

80-897 for 101 Foot<br />

80-925 for 100 Foot<br />

The Foot Pad levels the Variable Spacing Foot so that the<br />

drilled hole is perpendicular to the surface. The projection<br />

length of the Foot Pad (xx) depends upon the projection length<br />

of the Template Boss, thickness of the Template and radius of<br />

the workpiece. See service literature for diagram.<br />

Wall Tank<br />

The 80-503 Wall Tank (2 gallon) can be<br />

conveniently located in the work area or tool<br />

crib. The Drill Point Lubricator can then be<br />

refilled via the quick disconnect fitting<br />

(included).<br />

Boelube®, MIcrolube®, or similar cutting<br />

lubricants work very well. A very small<br />

amount is required to properly lubricate the<br />

cutting tool.<br />

Template Boss<br />

1. Determine Template Hole<br />

Diameter and Thickness.<br />

2. Select the proper Template<br />

Boss from the chart below.<br />

3. Boss length “L” must be<br />

greater than Template<br />

Thickness.<br />

Boss<br />

Length “L”<br />

Boss Diameter<br />

Template Boss Boss Boss<br />

Hole Dia. Projection “C” I.D. Part No.<br />

.500 .062 .39 44-203<br />

.500 .100 .39 44-212<br />

.500 .150 .39 44-215<br />

.625 .062 .51 44-202<br />

.625 .100 .51 44-211<br />

.625 .150 .51 44-214<br />

.750 .100 .64 44-210<br />

.750 .150 .64 44-213<br />

.875 .150 .69 44-221<br />

.875 .200 .69 44-259<br />

1.000 .080 .81 44-222<br />

1.000 .100 .81 44-208<br />

1.000 .150 .81 44-209<br />

1.000 .175 .81 44-281<br />

1.125 .100 1.00 44-204<br />

1.125 .150 1.00 44-220<br />

1.250 .200 1.12 44-253<br />

Other combinations of Hole Diameter (1.25” max.) and Length<br />

“L” can be provided.<br />

Handling Ring (for P2 and P3 Drills)<br />

A 9” diameter, rubber covered, ring that encircles and protects<br />

the P3 when it is laid down. It also provides a convenient way<br />

to carry the tool. The Handling Ring can be used with an<br />

overhead balancer to put the spindle in a horizontal position.<br />

Handling Ring number 58-316 fits the P33.<br />

Handling Ring number 58-271-02 fits the P32 and P34.<br />

Handling Ring number 56-095 fits the P2.<br />

Spindle Collets<br />

Part No. Size<br />

Series 200 Collets<br />

204 .125” 0.125<br />

46-500-141 .1406” 0.141<br />

205 .1563” 0.156<br />

46-500-172 .1719” 0.172<br />

206 .1875” 0.187<br />

46-500-203 .2031” 0.203<br />

207 .2188” 0.219<br />

46-500-234 .2344” 0.234<br />

213 6 mm 0.236<br />

208 .25” 0.250<br />

46-500-265 .2656” 0.265<br />

209 .2813” 0.281<br />

46-500-297 .2969” 0.297<br />

210 .3125” 0.313<br />

46-500-328 .3281” 0.328<br />

211 .3438” 0.344<br />

46-500-359 .3594” 0.359<br />

212 .375” 0.375<br />

46-500-390 .3906” 0.390<br />

Add “C” to the part number for use with Thru-the-Spindle<br />

Coolant. Slots are filled with elastomer.<br />

Spindle Adapters<br />

Spindle Adapter for Threaded Shank Cutters (use with number<br />

212 Collet)<br />

Part Thread x Body Overall<br />

Number Diameter Length<br />

32-009 .25”-28 x 0.375” 2.4<br />

32-048 .25”-28 x 0.375” 4.0<br />

32-049 .25”-28 x 0.375” 6.0<br />

32-050-1 .25”-28 x 0.500” 2.5<br />

32-050-2 .25”-28 x 0.500” 4.0<br />

32-050-3 .25”-28 x 0.500” 3.5<br />

32-050-4 .25”-28 x 0.500” 5.0<br />

32-050-5 .25”-28 x 0.500” 4.2<br />

32-050-6 .25”-28 x 0.500” 5.7<br />

32-050-7 .25”-28 x 0.500” 5.2<br />

32-050-8 .25”-28 x 0.500” 6.7<br />

32-050-9 .25”-28 x 0.500” 4.7<br />

32-071-1 .25”-28 x 0.625” 2.5<br />

32-071-2 .25”-28 x 0.625” 4.0<br />

32-071-3 .25”-28 x 0.625” 3.5<br />

32-071-4 .25”-28 x 0.625” 5.0<br />

32-071-5 .25”-28 x 0.625” 4.2<br />

32-071-6 .25”-28 x 0.625” 5.7<br />

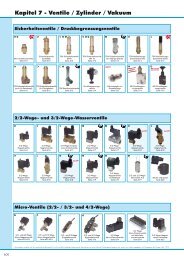

82-135 Venturi Vacuum (for P3 Drills)<br />

Replace the motor muffler. The air motor exhaust is routed<br />

through a venturi port to create a vacuum. The vacuum is then<br />

used to pick up dust and small chips that are hazardous to the<br />

environment. The dust and chips are collected in a disposable<br />

bag.<br />

27-055 Inlet Manifold (for P3 Drills)<br />

Used when mounting the P3 for stationary applications.<br />

Provides two NPT ports for using an external 4-way valve.<br />

Replaces the handle.<br />

527696 Foot Valve (for P3 Drills)<br />

Spring loaded 4-way vale: can be used with 27-055 Manifold<br />

for Foot operation of the P3. Includes foot shield.<br />

82-104 Rear Bail (for P3 Drills)<br />

A convenient mount for an overhead balancer. Puts the spindle<br />

of the P3 in the vertical position.<br />

4-18 4-19