AerospaceIndustry - Frank Drucklufttechnik

AerospaceIndustry - Frank Drucklufttechnik

AerospaceIndustry - Frank Drucklufttechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

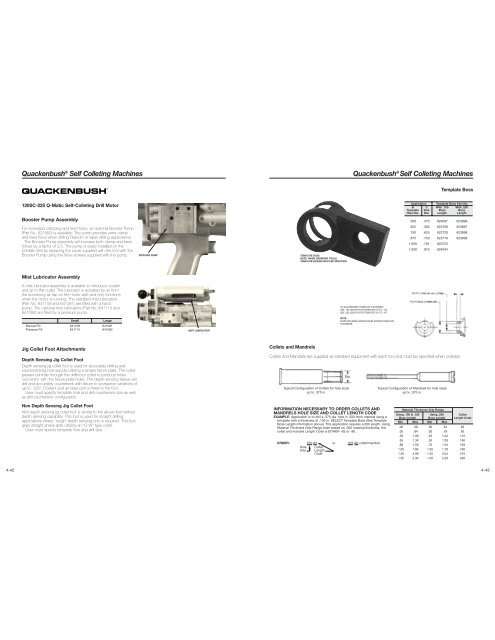

Quackenbush ® Self Colleting Machines Quackenbush ® Self Colleting Machines<br />

120SC-225 Q-Matic Self-Colleting Drill Motor<br />

Booster Pump Assembly<br />

For increased clamping and feed force, an optional Booster Pump<br />

(Part No. 621950) is available. The pump provides extra clamp<br />

and feed force when drilling Titanium or taper drilling applications.<br />

The Booster Pump assembly will increase both clamp and feed<br />

forces by a factor of 2.5. The pump is easily installed on the<br />

Q-Matic Drill by replacing the cover supplied with the tool with the<br />

Booster Pump using the three screws supplied with the pump.<br />

Mist Lubricator Assembly<br />

A mist lubricator assembly is available to introduce coolant<br />

and air to the cutter. The lubricator is actuated by air from<br />

the accessory air tap on the motor side and only functions<br />

when the motor is running. The standard mist lubricators<br />

(Part No. 641109 and 641081) are filled with a hand<br />

pump. The optional mist lubricators (Part No. 641110 and<br />

641082) are filled by a pressure pump.<br />

Small Large<br />

Manual Fill 641109 641081<br />

Pressure Fill 641110 641082<br />

Jig Collet Foot Attachments<br />

Depth Sensing Jig Collet Foot<br />

Depth sensing jig collet foot is used for accurately drilling and<br />

countersinking hole layouts utilizing a simple fixture plate. The cutter<br />

passes centrally through the drillmotor collet to produce holes<br />

concentric with the fixture plate holes. The depth sensing sleeve will<br />

drill and accurately countersink with fixture-to-workpiece variations of<br />

up to .125”. Coolant and air blast port is fitted to the foot.<br />

User must specify template hole and drill-countersink size as well<br />

as drill-countersink configuration.<br />

Non Depth Sensing Jig Collet Foot<br />

Non depth sensing jig collet foot is similar to the above foot without<br />

depth sensing capability. This foot is used for straight drilling<br />

applications where "rough" depth sensing only is required. This foot<br />

grips straight shank drills utilizing an "O-W" type collet.<br />

User must specify template hole and drill size.<br />

BOOSTER PUMP<br />

MIST LUBRICATOR<br />

TEMPLATE BOSS<br />

NOTE: WHEN ORDERING TOOLS,<br />

TEMPLATE BOSSES MUST BE SPECIFIED.<br />

Template Boss<br />

Application Template Boss Part No.<br />

B C With .150 With .200<br />

Template Sink Boss Boss<br />

Hole Dia. Dia. Length Length<br />

.500 .375 624087 623896<br />

.625 .500 623708 623897<br />

.750 .625 623720 623898<br />

.875 .750 623716 623899<br />

1.000 .781 623725<br />

1.000 .875 624034<br />

Collets and Mandrels<br />

Collets and Mandrels are supplied as standard equipment with each tool and must be specified when ordered.<br />

Typical Configuration of Collets for hole sizes<br />

up to .375 in.<br />

TO ACCOMODATE TEMPLATE THICKNESS:<br />

USE .150 LENGTH FOR TEMPLATE UP TO .125<br />

USE .200 LENGTH FOR TEMPLATE UP TO .187<br />

NOTE:<br />

TEMPLATE BOSS LENGTH MUST EXCEED TEMPLATE<br />

THICKNESS.<br />

INFORMATION NECESSARY TO ORDER COLLETS AND<br />

MANDRELS HOLE SIZE AND COLLET LENGTH CODE<br />

EXAMPLE: Application is to drill a .375 dia. hole in .500 thick material using a<br />

template with a thickness of .130 in. SELECT Template Boss (See Template<br />

Boss Length information above). This application requires a.200 length. Using<br />

Material Thickness Grip Range chart based on .500 material thickness, the<br />

collet and mandrel Length Code is EITHER -63 or -90.<br />

ORDER: 375-63 or .375-90 collet/mandrel<br />

Hole Collet<br />

Size Length<br />

Code<br />

Typical Configuration of Mandrels for hole sizes<br />

up to .375 in.<br />

Material Thickness Grip Range<br />

Using .100 & .150 Using .200 Collet<br />

Boss Length Boss Length Length Code<br />

Min Max Min Max<br />

.00 .59 .00 .54 63<br />

.05 .84 .00 .79 90<br />

.30 1.09 .25 1.04 115<br />

.55 1.34 .50 1.29 140<br />

.80 1.59 .75 1.54 163<br />

1.05 1.84 1.00 1.79 190<br />

1.30 2.09 1.25 2.04 215<br />

1.55 2.34 1.50 2.29 240<br />

4-42 4-43