- Page 1 and 2:

Mitglied Mitglied der der Helmholtz

- Page 4 and 5:

Forschungszentrum Jülich GmbH Inst

- Page 6 and 7:

TABLE OF CONTENTS 1 Preface .......

- Page 8:

6.2.2 Doctoral Thesis .............

- Page 11 and 12:

state of NRW. The collaborative pro

- Page 13 and 14:

2 Institute’s Profile Due to the

- Page 15 and 16:

2.2. Organization chart Reactor Saf

- Page 17 and 18:

3 Key Research Topics 3.1. Long Ter

- Page 19 and 20:

actinide co-conversion into polyact

- Page 21 and 22:

Fig. 7: Non-destructive analytical

- Page 23 and 24:

Fig. 9: Thermal treatment of an AVR

- Page 25 and 26:

3.8. Product Quality Control of Rad

- Page 27 and 28:

3.8.2 Product Quality Control of Lo

- Page 29 and 30:

The advantage of working at low vac

- Page 31 and 32:

NdPO 4 powder sample, directly rece

- Page 33 and 34:

4.5. Non-destructive assay testing

- Page 35 and 36:

5 Scientific and Technical Reports

- Page 37 and 38:

Results and Discussion The irradiat

- Page 39 and 40: work will focus on the identificati

- Page 41 and 42: Different solvents (iso-propanol an

- Page 43 and 44: e & j) Aggregates of aluminium oxid

- Page 45 and 46: Experimental details The corrosion

- Page 47 and 48: Intensity [CPS] 500 400 300 200 100

- Page 49 and 50: Fig. 24: Left: High resolution TEM

- Page 51 and 52: a) MD model [10] b) Derived Lesukit

- Page 53 and 54: 5.4. Minor actinide(III) recovery f

- Page 55 and 56: Extensive extraction studies were p

- Page 57 and 58: of the extraction properties of the

- Page 59 and 60: Cm(III) together with the lanthanid

- Page 61 and 62: using a mixture of CyMe4BTBP and TO

- Page 63 and 64: A more challenging route studied wi

- Page 65 and 66: These preliminary results show that

- Page 67 and 68: The 1-cycle SANEX process is intend

- Page 69 and 70: Continuous counter-current tests us

- Page 71 and 72: Conclusion In this work, it was sho

- Page 73 and 74: shaken by a vortex mixer for 15 min

- Page 75 and 76: 100 100 Distribution ratio 10 1 0.1

- Page 77 and 78: Tab. 15: The distribution ratios of

- Page 79 and 80: 5.7. Synthesis and thermal treatmen

- Page 81 and 82: Acid-Deficient Uranyl-Nitrate via d

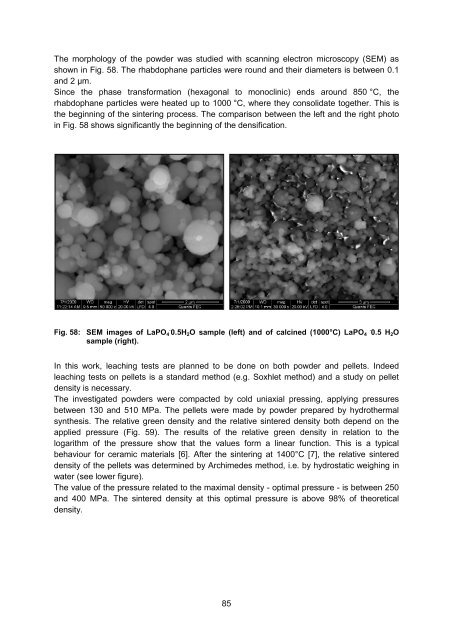

- Page 83 and 84: Optical investigation showed a noti

- Page 85 and 86: TG /% 100 98 96 94 92 90 88 86 84 8

- Page 87 and 88: Radiolysis in the aqueous solutions

- Page 89: is about 4% while the one of the rh

- Page 93 and 94: Conclusion and outlook Monazite-typ

- Page 95 and 96: Fig. 63: Description of the unit ce

- Page 97 and 98: agents for the synthesis of neodymi

- Page 99 and 100: 100 TG 785°C Exo DSC 0,2 0,0 90 -0

- Page 101 and 102: After synthesis the product was cen

- Page 103 and 104: process of monazite and additional

- Page 105 and 106: Tab. 18: Lattice parameters determi

- Page 107 and 108: Conclusions For Sm 1-x Ce x PO 4 mo

- Page 109 and 110: 5.11. Raman Spectra of Synthetic Ra

- Page 111 and 112: The numerical values of all measure

- Page 113 and 114: knowledge, these special relationsh

- Page 115 and 116: Fig. 80: Raman spectra of LaPO 4 ir

- Page 117 and 118: 5.12. MC simulation of thermal neut

- Page 119 and 120: content was replaced by hydrogen. C

- Page 121 and 122: constant for hydrogen concentration

- Page 123 and 124: with a 0 1 -183.88 ± 8.55 and a 2

- Page 125 and 126: 5.13. An Improved Method for the no

- Page 127 and 128: 2 2 2 d0 R ds d0 dw la( )

- Page 129 and 130: The relative uncertainty for the ac

- Page 131 and 132: In the drum, 4 ‘hot spots’ for

- Page 133 and 134: activity of Cs-137 is much more und

- Page 135 and 136: gamma-ray detector approximated by

- Page 137 and 138: shown in Fig. 96. In both cases the

- Page 139 and 140: econstruction than the old calculat

- Page 141 and 142:

Neutron capture cross sections and

- Page 143 and 144:

Outlook The evaluated data will be

- Page 145 and 146:

from carbon-based HTR fuel elements

- Page 147 and 148:

Fig. 102: 3D volume reconstructions

- Page 149 and 150:

dislocate the 14 C atom from its pr

- Page 151 and 152:

It can be seen that nearly all trit

- Page 153 and 154:

Acknowledgement The authors like to

- Page 155 and 156:

development by investigations of ga

- Page 157 and 158:

Fig. 109: The left picture shows th

- Page 159 and 160:

[2] A European Roadmap for Developi

- Page 161 and 162:

from airborne SWIR Full Spectrum Im

- Page 163 and 164:

Fig. 113: Visualization of the vege

- Page 165 and 166:

number of training samples up to 19

- Page 167 and 168:

Acknowledgements The work presented

- Page 169 and 170:

three approaches has severe drawbac

- Page 171 and 172:

neighbours from the list of merge c

- Page 173 and 174:

it gives a difference in segmentati

- Page 175 and 176:

[6] I. Niemeyer, F. Bachmann, A. Jo

- Page 177 and 178:

Monitoring 3 cooperated intensively

- Page 179 and 180:

facilities and other treaty related

- Page 181 and 182:

parameters of the SAR system, such

- Page 183 and 184:

The MGD products used in the study

- Page 185 and 186:

Fig. 134 contains the result for th

- Page 187 and 188:

[2] H. Maître (ed.), Processing of

- Page 189 and 190:

Preparatory Committee to allocate t

- Page 191 and 192:

unconditional security assurances f

- Page 193 and 194:

safeguards was also requested. Deci

- Page 195 and 196:

[16] United Nations Security Counci

- Page 197 and 198:

5.24. Development and Application o

- Page 199 and 200:

Hardware layer The hardware layer i

- Page 201 and 202:

So in most applications the scale u

- Page 203 and 204:

The ENDF-B/V and ENDF-B/VI librarie

- Page 205 and 206:

5.26. Product control of waste prod

- Page 207 and 208:

Polysiloxane which has been investi

- Page 209 and 210:

acceptance requirements [3]. In the

- Page 211 and 212:

Fig. 145: List of description and d

- Page 213 and 214:

6.1. Courses taught at universities

- Page 215 and 216:

Umwelt / Energy & Environment 2010;

- Page 217 and 218:

6.5. Institute Seminar The IEK-6 or

- Page 219 and 220:

6.5.3 Invited talks 2009 30.04.2009

- Page 221 and 222:

21.09.2010 Dr. N. Evans: The Chemis

- Page 223 and 224:

8 Selected R&D projects 8.1. EU pro

- Page 225 and 226:

K. Aymanns: Nominated as deputy re

- Page 227 and 228:

Bukaemskiy A.A., Barrier D., Modolo

- Page 229 and 230:

11.2. Publications 2009 11.2.1 Jour

- Page 231 and 232:

Rezniczek, A.; Richter, B.; Jussofi

- Page 233 and 234:

Daniels, H.: Co-conversion of actin

- Page 235 and 236:

11.3. Publications 2010 11.3.1 Jour

- Page 237 and 238:

Sypula, M.; Wilden, A.; Schreinemac

- Page 239 and 240:

(Partitioning) - Stabilitätsunters

- Page 241 and 242:

Modolo, G.; Bosbach, D.; Geist, A.;

- Page 243 and 244:

12 How to reach us Postal Address F

- Page 245 and 246:

By train: Take the train from Aache

- Page 247 and 248:

Schriften des Forschungszentrums J

- Page 249 and 250:

Schriften des Forschungszentrums J

- Page 251 and 252:

Schriften des Forschungszentrums J

- Page 253 and 254:

Schriften des Forschungszentrums J

- Page 255 and 256:

Schriften des Forschungszentrums J

- Page 257 and 258:

Schriften des Forschungszentrums J

- Page 259:

Schriften des Forschungszentrums J