Caterpillar Marine - Marine Engines Caterpillar

Caterpillar Marine - Marine Engines Caterpillar

Caterpillar Marine - Marine Engines Caterpillar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

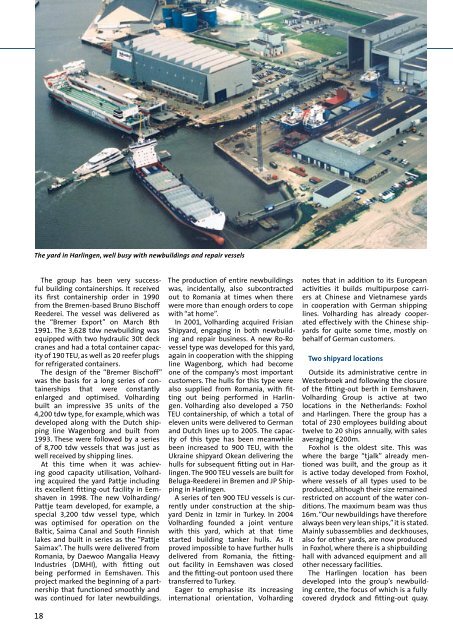

The yard in Harlingen, well busy with newbuildings and repair vessels<br />

The group has been very successful<br />

building containerships. It received<br />

its first containership order in 1990<br />

from the Bremen-based Bruno Bischoff<br />

Reederei. The vessel was delivered as<br />

the “Bremer Export” on March 8th<br />

1991. The 3,628 tdw newbuilding was<br />

equipped with two hydraulic 30t deck<br />

cranes and had a total container capacity<br />

of 190 TEU, as well as 20 reefer plugs<br />

for refrigerated containers.<br />

The design of the “Bremer Bischoff”<br />

was the basis for a long series of containerships<br />

that were constantly<br />

enlarged and optimised. Volharding<br />

built an impressive 35 units of the<br />

4,200 tdw type, for example, which was<br />

developed along with the Dutch shipping<br />

line Wagenborg and built from<br />

1993. These were followed by a series<br />

of 8,700 tdw vessels that was just as<br />

well received by shipping lines.<br />

At this time when it was achieving<br />

good capacity utilisation, Volharding<br />

acquired the yard Pattje including<br />

its excellent fitting-out facility in Eemshaven<br />

in 1998. The new Volharding/<br />

Pattje team developed, for example, a<br />

special 3,200 tdw vessel type, which<br />

was optimised for operation on the<br />

Baltic, Saima Canal and South Finnish<br />

lakes and built in series as the “Pattje<br />

Saimax”. The hulls were delivered from<br />

Romania, by Daewoo Mangalia Heavy<br />

Industries (DMHI), with fitting out<br />

being performed in Eemshaven. This<br />

project marked the beginning of a partnership<br />

that functioned smoothly and<br />

was continued for later newbuildings.<br />

18<br />

The production of entire newbuildings<br />

was, incidentally, also subcontracted<br />

out to Romania at times when there<br />

were more than enough orders to cope<br />

with “at home”.<br />

In 2001, Volharding acquired Frisian<br />

Shipyard, engaging in both newbuilding<br />

and repair business. A new Ro-Ro<br />

vessel type was developed for this yard,<br />

again in cooperation with the shipping<br />

line Wagenborg, which had become<br />

one of the company’s most important<br />

customers. The hulls for this type were<br />

also supplied from Romania, with fitting<br />

out being performed in Harlingen.<br />

Volharding also developed a 750<br />

TEU containership, of which a total of<br />

eleven units were delivered to German<br />

and Dutch lines up to 2005. The capacity<br />

of this type has been meanwhile<br />

been increased to 900 TEU, with the<br />

Ukraine shipyard Okean delivering the<br />

hulls for subsequent fitting out in Harlingen.<br />

The 900 TEU vessels are built for<br />

Beluga-Reederei in Bremen and JP Shipping<br />

in Harlingen.<br />

A series of ten 900 TEU vessels is currently<br />

under construction at the shipyard<br />

Deniz in Izmir in Turkey. In 2004<br />

Volharding founded a joint venture<br />

with this yard, which at that time<br />

started building tanker hulls. As it<br />

proved impossible to have further hulls<br />

delivered from Romania, the fittingout<br />

facility in Eemshaven was closed<br />

and the fitting-out pontoon used there<br />

transferred to Turkey.<br />

Eager to emphasise its increasing<br />

international orientation, Volharding<br />

notes that in addition to its European<br />

activities it builds multipurpose carriers<br />

at Chinese and Vietnamese yards<br />

in cooperation with German shipping<br />

lines. Volharding has already cooperated<br />

effectively with the Chinese shipyards<br />

for quite some time, mostly on<br />

behalf of German customers.<br />

Two shipyard locations<br />

Outside its administrative centre in<br />

Westerbroek and following the closure<br />

of the fitting-out berth in Eemshaven,<br />

Volharding Group is active at two<br />

locations in the Netherlands: Foxhol<br />

and Harlingen. There the group has a<br />

total of 230 employees building about<br />

twelve to 20 ships annually, with sales<br />

averaging €200m.<br />

Foxhol is the oldest site. This was<br />

where the barge “tjalk” already mentioned<br />

was built, and the group as it<br />

is active today developed from Foxhol,<br />

where vessels of all types used to be<br />

produced, although their size remained<br />

restricted on account of the water conditions.<br />

The maximum beam was thus<br />

16m. “Our newbuildings have therefore<br />

always been very lean ships,” it is stated.<br />

Mainly subassemblies and deckhouses,<br />

also for other yards, are now produced<br />

in Foxhol, where there is a shipbuilding<br />

hall with advanced equipment and all<br />

other necessary facilities.<br />

The Harlingen location has been<br />

developed into the group’s newbuilding<br />

centre, the focus of which is a fully<br />

covered drydock and fitting-out quay.