Caterpillar Marine - Marine Engines Caterpillar

Caterpillar Marine - Marine Engines Caterpillar

Caterpillar Marine - Marine Engines Caterpillar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

which frequently corresponded to over<br />

15% of deadweight, were absolutely<br />

vital to achieve the necessary stability,<br />

but were otherwise useless „cargo“.<br />

This inconvenience could generally be<br />

avoided by building wider ships,<br />

although these could no longer<br />

pass through the Panama<br />

Canal. And the industry was still<br />

rather reluctant about deciding<br />

on these at that time. Germanischer<br />

Lloyd later developed a<br />

method for reducing the ballast<br />

water volume, making it possible<br />

to carry up to 200 TEU more<br />

on board.<br />

Fast growth in ship<br />

capacities<br />

Following the commissioning<br />

of the first containerships<br />

that were too large to pass<br />

the Panama Canal, the Post-<br />

Panamax vessels as we have<br />

already mentioned, after some<br />

initial hesitation the dam was<br />

quickly broken. Although as<br />

late as 1992 the trade journal<br />

„Deutsche Verkehrs-Zeitung“<br />

commented rather sceptically<br />

that „The 6,000 TEU ship is no<br />

Utopia“, a first feasibility study<br />

for the construction of 8,000<br />

TEU vessels was drawn up in<br />

the same year. It initially met a<br />

very cool reception, but only a<br />

little later, in 2003, the breakthrough<br />

for this size class, today<br />

regarded as standard in the<br />

East-West trades, was achieved.<br />

Over 80 newbuildings of this<br />

size were on the orderbooks of<br />

South Korean shipyards at the<br />

end of 2003. At the same time, a series<br />

of 9,500 TEU vessels had been ordered.<br />

And of the 1,124 containerships with<br />

a total capacity of 4.1m TEU ordered<br />

globally during 2005, 2.2m TEU (about<br />

55%) was accounted for by vessels with<br />

a capacity of 5,000 TEU upwards. The<br />

13,000 TEU vessel is already now being<br />

discussed. A first series is being built<br />

at Odense Shipyard, which belongs to<br />

Maersk Group. However, this yard is<br />

always very discreet when it comes to<br />

announcing technical details. It is certain<br />

that the technical aspects of the<br />

13,000 TEU giant have meanwhile been<br />

settled. Germanischer Lloyd has presented<br />

a relevant design with the South<br />

26<br />

Korean Hyundai shipyard. In view of<br />

the previous development, it will probably<br />

be only a matter of time before<br />

the first orders for it are placed and<br />

outside Europe. It remains to be seen<br />

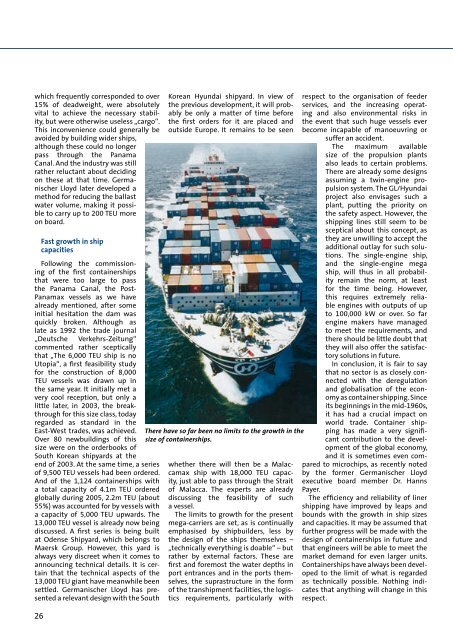

There have so far been no limits to the growth in the<br />

size of containerships.<br />

whether there will then be a Malaccamax<br />

ship with 18,000 TEU capacity,<br />

just able to pass through the Strait<br />

of Malacca. The experts are already<br />

discussing the feasibility of such<br />

a vessel.<br />

The limits to growth for the present<br />

mega-carriers are set, as is continually<br />

emphasised by shipbuilders, less by<br />

the design of the ships themselves –<br />

„technically everything is doable“ – but<br />

rather by external factors. These are<br />

first and foremost the water depths in<br />

port entrances and in the ports themselves,<br />

the suprastructure in the form<br />

of the transhipment facilities, the logistics<br />

requirements, particularly with<br />

respect to the organisation of feeder<br />

services, and the increasing operating<br />

and also environmental risks in<br />

the event that such huge vessels ever<br />

become incapable of manoeuvring or<br />

suffer an accident.<br />

The maximum available<br />

size of the propulsion plants<br />

also leads to certain problems.<br />

There are already some designs<br />

assuming a twin-engine propulsion<br />

system. The GL/Hyundai<br />

project also envisages such a<br />

plant, putting the priority on<br />

the safety aspect. However, the<br />

shipping lines still seem to be<br />

sceptical about this concept, as<br />

they are unwilling to accept the<br />

additional outlay for such solutions.<br />

The single-engine ship,<br />

and the single-engine mega<br />

ship, will thus in all probability<br />

remain the norm, at least<br />

for the time being. However,<br />

this requires extremely reliable<br />

engines with outputs of up<br />

to 100,000 kW or over. So far<br />

engine makers have managed<br />

to meet the requirements, and<br />

there should be little doubt that<br />

they will also offer the satisfactory<br />

solutions in future.<br />

In conclusion, it is fair to say<br />

that no sector is as closely connected<br />

with the deregulation<br />

and globalisation of the economy<br />

as container shipping. Since<br />

its beginnings in the mid-1960s,<br />

it has had a crucial impact on<br />

world trade. Container shipping<br />

has made a very significant<br />

contribution to the development<br />

of the global economy,<br />

and it is sometimes even compared<br />

to microchips, as recently noted<br />

by the former Germanischer Lloyd<br />

executive board member Dr. Hanns<br />

Payer.<br />

The efficiency and reliability of liner<br />

shipping have improved by leaps and<br />

bounds with the growth in ship sizes<br />

and capacities. It may be assumed that<br />

further progress will be made with the<br />

design of containerships in future and<br />

that engineers will be able to meet the<br />

market demand for even larger units.<br />

Containerships have always been developed<br />

to the limit of what is regarded<br />

as technically possible. Nothing indicates<br />

that anything will change in this<br />

respect.