Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Author's personal copy<br />

<strong>Fuel</strong> <strong>Processing</strong> <strong>for</strong> <strong>Fuel</strong> <strong>Cells</strong> 13<br />

smaller amounts from cracking processes of higher hydrocarbons. The<br />

most common commercialized products <strong>for</strong> LPG are mixtures of propane<br />

and butane, which exhibit the highest specific hydrogen content among<br />

fossil fuels and, taking the weight of the hydrogen storage tank into<br />

account, could even exceed that of liquefied hydrogen (Muradov, 2003).<br />

3.3.2 Gasoline<br />

Gasoline is a middle distillate fraction of crude oil blended with several<br />

other hydrocarbon and polymer compo<strong>und</strong>s. Originally, gasoline was a<br />

waste product of the refinery process used <strong>for</strong> producing kerosene from<br />

petroleum. Due to its high combustion energy, it became the preferred<br />

automobile fuel. Today’s gasoline production is per<strong>for</strong>med in a three-step<br />

process at the refinery. First, crude oil is distillated and separated in<br />

different fractions by boiling ranges. In a second step, refinement of these<br />

fractions by means of cracking, branching/isomerization, and aromatizing<br />

is per<strong>for</strong>med. In the last step, unwanted contents, such as sulfur, are<br />

removed. There<strong>for</strong>e, gasoline is a mixture of several h<strong>und</strong>reds of hydrocarbons,<br />

alkanes, including cycloalkanes, alkenes, and aromatics (Table 4),<br />

and has a boiling range from 50 Cto200 C. Commercial gasoline is a<br />

blend of different refinery fractions, which meets specified physical properties<br />

required <strong>for</strong> modern internal combustion engines. These specifications<br />

(e.g., EN 228 in Europe allows up to 5 vol.% bioethanol in gasoline) are<br />

regulated by the legislative authorities. Furthermore, additional additives<br />

are solved in the gasoline fuel. These additives are organic compo<strong>und</strong>s that<br />

enhance certain per<strong>for</strong>mance characteristics or provide characteristics not<br />

inherent in the gasoline. Typically, additives are added in the ppm concentration<br />

range. Additives in commercial gasoline are antioxidants, corrosion<br />

inhibitors, demulsifiers, dyes and markers, anti-icing agents, and drag<br />

reducers. Most of them are organic alcohols or acids, polymers, soluble<br />

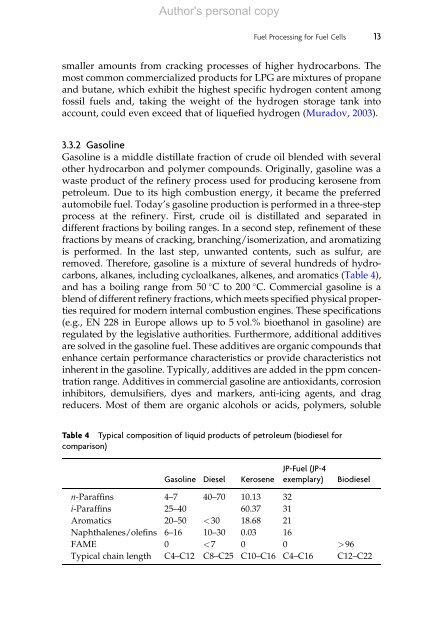

Table 4 Typical composition of liquid products of petroleum (biodiesel <strong>for</strong><br />

comparison)<br />

Gasoline Diesel Kerosene<br />

JP-<strong>Fuel</strong> (JP-4<br />

exemplary)<br />

Biodiesel<br />

n-Paraffins 4–7 40–70 10.13 32<br />

i-Paraffins 25–40 60.37 31<br />

Aromatics 20–50