Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Author's personal copy<br />

50 Torsten Kaltschmitt and Olaf Deutschmann<br />

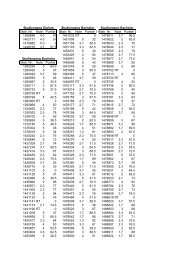

The Beretta group (Politecnico di Milano) has recently been able to<br />

show by a quartz capillary sampling technique that olefins are <strong>for</strong>med<br />

even in the initial catalyst section over a Rh/alumina catalysts in CPOX of<br />

propane (Donazzi et al., 2011), which clearly reveals that the application of<br />

two-zone model is risky. In these models, it is assumed that, in the first<br />

section of the catalyst, only catalytic conversion is significant, and then,<br />

further downstream, only gas-phase chemistry needs to be considered.<br />

In the experiment, the downstream part of the catalyst is coked-up;<br />

here, the Rh surface cannot act as a sink <strong>for</strong> radicals. The study also<br />

numerically simulated the coverage of the Rh catalyst as a function of<br />

the axial coordinate, revealing a sufficient number of unoccupied surface<br />

sites at lean (C/O¼0.8) conditions (Figure 15 (left)). At rich conditions<br />

(C/O ¼1.2; Figure 15 (right)), however, the surface further downstream is<br />

completely covered by carbon. This study (Hartmann et al., 2010) also<br />

revealed that the applied chemical models—even the most detailed ones<br />

available—need further improvement, in particular regarding the <strong>for</strong>mation<br />

of minor by-products at rich conditions.<br />

7.2 Predicting and controlling coking in fuel re<strong>for</strong>mers<br />

7.2.1 Catalyst deactivation due to coking<br />

The model discussed above predicts a surface completely covered by<br />

carbon, C(s), in the downstream section of the catalyst, z>1 mm. Since<br />

the model does not include direct interactions between gas-phase species<br />

and carbon on the surface, the gas-phase conversion practically proceeds<br />

Surface coverage<br />

1E+00<br />

Rh (s)<br />

1E+00<br />

1E-01<br />

CO (s)<br />

Rh (s)<br />

1E-01<br />

CO<br />

1E-02<br />

H (s)<br />

1E-02<br />

1E-03<br />

1E-03<br />

H O<br />

C (s)<br />

1E-04<br />

1E-04<br />

O (s)<br />

C<br />

1E-05<br />

1E-05<br />

OH (s)<br />

1E-06<br />

OH (s)<br />

1E-06<br />

1E-07<br />

H 2 O (s)<br />

1E-07<br />

H 2 O (s)<br />

1E-08<br />

1E-08 <strong>Fuel</strong>-rich conditions—enlarged<br />

1E-09<br />

1E-09<br />

CO 2 CO 2 (s)<br />

1E-10<br />

1E-10<br />

0.0 2.5 5.0 7.5 10.0<br />

0.0 0.3 0.5 0.8 1.0<br />

Axial position [mm]<br />

Axial position [mm]<br />

Figure 15 Numerically predicted surface coverage as a function of axial position along<br />

the honeycomb catalyst channel in CPOX of iso-octane over a Rh/alumina-coated<br />

monolith. Conditions: C/O¼0.8, 1359 K (left), C/O¼1.2, 1076 K (right); taken from<br />

Hartmann et al. (2010).<br />

Surface coverage