Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Author's personal copy<br />

Heat transport in solid wall<br />

36 Torsten Kaltschmitt and Olaf Deutschmann<br />

Transport of<br />

momentum,<br />

energy,<br />

species<br />

Gas-phase<br />

reactions<br />

Thermal<br />

radiation<br />

Diffusion<br />

Adsorption,<br />

surface reactions,<br />

desorption<br />

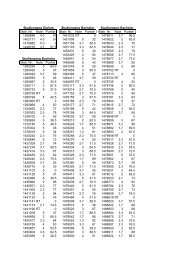

Figure 9 Sketch of the physical and chemical processes occurring in a catalyst-coated<br />

honeycomb monolith. Many length and time scales have to be considered simultaneously<br />

reaching from a scale of nanometer and picosecond (e.g., surface reactions),<br />

to one of micro/millimeter and micro/millisecond (e.g., internal/external diffusion),<br />

and to one of centimeter and second (e.g., heat transport in solid structures); taken from<br />

Janardhanan and Deutschman (2011).<br />

and intermediates desorb and diffuse back into the bulk flow. Due to the<br />

high temperatures, the chemical species may also react homogeneously in<br />

the gas phase. In catalytic reactors, the catalyst material is often dispersed<br />

in porous structures such as washcoats or pellets. Mass transport in the<br />

fluid phase and chemical reactions are then superimposed by diffusion of<br />

the species to the active catalytic centers in the pores. The temperature<br />

distribution depends on the interaction between heat convection and<br />

conduction in the fluid, heat generation/consumption due to chemical<br />

reactions, heat transport in the solid material, and thermal radiation. Both<br />

variation of the feed conditions in time and space and heat transfer<br />

between the reactor and the ambience result in a nonuni<strong>for</strong>m temperature<br />

distribution over the entire monolith, which means that the behavior will<br />

differ from channel to channel (Windmann et al., 2003).<br />

The challenge in catalytic fuel processing is not only the development<br />

of new catalysts to obtain the desired product, but also the <strong>und</strong>erstanding<br />

of the interaction of the catalyst with the surro<strong>und</strong>ing reactive flow field.<br />

Sometimes, the use of these interactions alone can lead to the desired<br />

product selectivity and yield. For detailed introductions into transport<br />

phenomena and their coupling with heterogeneous reactions, readers are