Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

Fuel Processing for Fuel Cells - Institut für Technische Chemie und ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Author's personal copy<br />

28 Torsten Kaltschmitt and Olaf Deutschmann<br />

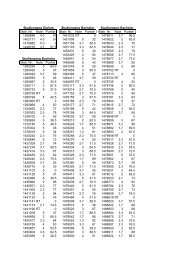

A<br />

1.0<br />

B<br />

1.0<br />

C<br />

1.0<br />

Conversion<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

0.6<br />

5 vol.%<br />

10 vol.%<br />

50 vol.%<br />

85 vol.%<br />

C 2 H 5 OH<br />

Conversion<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

0.8 1.0 1.2 1.4 1.6 0.6<br />

C/O<br />

i-C 8 H 18<br />

Yield<br />

0.8<br />

0.6<br />

0.4<br />

i-octane<br />

5 vol.%<br />

5 vol.%<br />

10 vol.%<br />

0.2 10 vol.%<br />

50 vol.%<br />

50 vol.%<br />

85 vol.%<br />

85 vol.%<br />

ethanol<br />

0.0<br />

0.8 1.0 1.2 1.4 1.6 0.6 0.8 1.0 1.2 1.4 1.6<br />

C/O<br />

C/O<br />

H 2<br />

Figure 7 C-based conversion of ethanol (A) and iso-octane (B), and hydrogen yield (C) as<br />

a function of the C/O ratio <strong>for</strong> CPOX of ethanol/iso-octane blends over a Rh/Al 2 O 3 -<br />

coated honeycomb monolith. Vol.% nomenclature denotes the molar percentage of<br />

ethanol in the blend. Taken from Diehm (2010).<br />

4.2.5 Diesel<br />

In comparison to natural gas and gasoline, diesel fuel has the higher<br />

hydrogen energy density. However, diesel is the more difficult fuel to<br />

re<strong>for</strong>m because diesel fuel is a mixture of a wide variety of paraffins,<br />

naphthenes, and aromatics, each of which reacts differently in a CPOX<br />

reaction, as discussed above and elsewhere (Hartmann et al., 2009a;<br />

Shekhawat et al., 2009; Subramanian et al., 2004). The usual occurrence<br />

of organosulfur compo<strong>und</strong>s will complicate the re<strong>for</strong>ming even more, in<br />

particular concerning catalyst deactivation.<br />

Rhodium-based catalysts were chosen <strong>for</strong> many studies of catalytic<br />

re<strong>for</strong>ming of diesel and its major components, not only because it was<br />

successfully applied <strong>for</strong> re<strong>for</strong>ming, in particular CPOX, of lighter<br />

hydrocarbons but also because it revealed low propensity <strong>for</strong> carbon<br />

<strong>for</strong>mation (Krummenacher and Schmidt, 2004; Krummenacher et al.,<br />

2003; O’Connor et al., 2000; Shekhawat et al., 2006; Subramanian<br />

et al., 2004; Thormann et al., 2009, 2008b). The study of Krummenacher<br />

et al. (2003) on CPOX of diesel over Rh/Al 2 O 3 -coated foam catalysts<br />

revealed that the highest hydrogen yields can be achieved when the<br />

reactor is operated at low C/O ratios, which are actually close to the<br />

flammability of the mixture shown in Figure 8. Furthermore,theoperation<br />

of diesel fuel at such low C/O ratios presents a challenge <strong>for</strong> the<br />

mixing and feeding of the reactants, and in particular, a much higher<br />

tendency to precombustion of the fuel upstream the catalytic section is<br />

observed. This transient behavior is less drastic when the single fuel<br />

components or their binary mixtures are used. The hydrogen yields<br />

show a maximum at C/O ratios closer to 1.0, and the reactor can be<br />

operated more safely (Hartmann et al., 2009a; Krummenacher and<br />

Schmidt, 2004; Krummenacher et al., 2003).