Pluto Safety PLC details - Products For Industry

Pluto Safety PLC details - Products For Industry

Pluto Safety PLC details - Products For Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

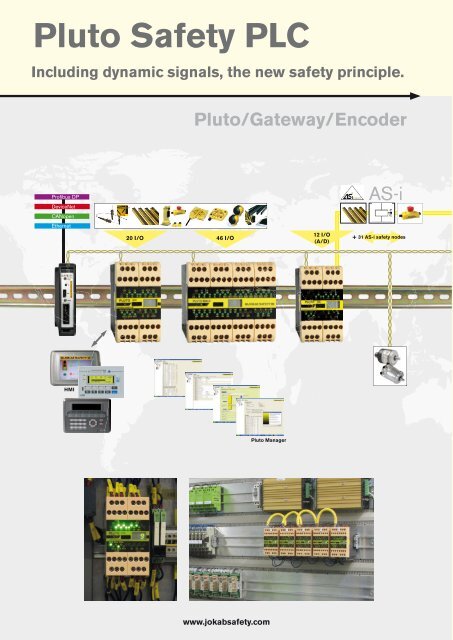

<strong>Pluto</strong> <strong>Safety</strong> <strong>PLC</strong><br />

Including dynamic signals, the new safety principle.<br />

<strong>Pluto</strong>/Gateway/Encoder<br />

Profibus DP<br />

DeviceNet<br />

CANopen<br />

Ethernet<br />

AS-i<br />

12 I/O<br />

20 I/O 46 I/O<br />

+ 31 AS-i safety nodes<br />

(A/D)<br />

HMI<br />

<strong>Pluto</strong> Manager<br />

www.jokabsafety.com

Contents<br />

Page<br />

Why you should use the <strong>Pluto</strong> safety <strong>PLC</strong> _______________________________2:2<br />

<strong>Pluto</strong> with and without a databus ______________________________________2:4<br />

_________________________________________________________2:6<br />

____________________________________________________2:8<br />

____________________________________________________ 2:10<br />

____________________________________________________ 2:11<br />

<strong>Pluto</strong> Manager ____________________________________________________ 2:12<br />

<strong>Pluto</strong> Gateway _____________________________________________________ 2:14<br />

__________________________________________________________ 2:16<br />

_________________________________________________________ 2:18<br />

_________________________________________________________ 2:20<br />

__________________________________________________________ 2:22<br />

Safe encoder ______________________________________________________ 2:24<br />

Example – Robot cell with <strong>Pluto</strong> _____________________________________ 2:28<br />

Electrical connections ______________________________________________ 2:29<br />

<strong>Pluto</strong> settings _____________________________________________________ 2:30<br />

<strong>PLC</strong> code <strong>Pluto</strong> ____________________________________________________ 2:32<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

Descriptions and examples in this book show how the products work and can be used. This does not mean that they can meet the requirements for<br />

all types of machines and processes. The purchaser/user is responsible for ensuring that the product is installed and used in accordance with the<br />

applicable regulations and standards. We reserve the right to make changes in products and product sheets without previous notice. <strong>For</strong> the latest<br />

updates, refer to www.jokabsafety.com. 2008.<br />

www.jokabsafety.com 2:1<br />

12<br />

13

Why you should<br />

have <strong>Pluto</strong> safety<br />

<strong>PLC</strong>'s.<br />

– for simplifying the design of and changes to safety systems!<br />

Approval:<br />

EN 954-1, Category 4<br />

EN 61496-1, Type 4<br />

<br />

<strong>Pluto</strong> is an ”All-Master” safety <strong>PLC</strong> concept, that simplifies<br />

the design of safety systems and achieves the highest safety<br />

<br />

<br />

between <strong>Pluto</strong> and conventional safety <strong>PLC</strong>´s is that there<br />

is no "Master-Slave" relationship between the control units<br />

connected to the safety bus. Each <strong>Pluto</strong> is a 'Master' unit and<br />

can see the other <strong>Pluto</strong>s' inputs and outputs, and can thereby<br />

make decisions about its own safety environment.<br />

This concept enables simple communication, programming<br />

and changes to the safety system. With the use of a 'Gateway'<br />

device, a <strong>Pluto</strong> can communicate with other bus systems<br />

and thereby form part of a larger network. Gateway units are<br />

available for several different bus systems, such as Profibus,<br />

<br />

safety slaves and standard slaves can be handled.<br />

<strong>Pluto</strong> offers an economic solution for both single machines<br />

and for major machine systems.<br />

Our solution with All-Master<br />

<strong>Pluto</strong> All-Master<br />

<strong>Pluto</strong> – All Master<br />

+ + <br />

<strong>Pluto</strong> All-Master<br />

<strong>Pluto</strong> All-Master<br />

4 + 4 + 4<br />

Traditional safety <strong>PLC</strong><br />

<br />

+<br />

<br />

nodes<br />

Master<br />

Safe bus<br />

4<br />

<strong>Pluto</strong> AS-i<br />

Slaves<br />

<br />

+<br />

<br />

6 + 4<br />

2:2<br />

www.jokabsafety.com

– to supervise safety devices!<br />

1<br />

Light beams Light grids/curtains <br />

devices<br />

Sensors/<br />

switches<br />

Two-hand<br />

controls<br />

Emergency<br />

stops<br />

Strips<br />

Mats<br />

2<br />

Most safety devices on the market can be connected directly<br />

to <strong>Pluto</strong> units. By using dynamic signals with sensors<br />

from Jokab <strong>Safety</strong> only one input is needed for category 4,<br />

<br />

is also possible to connect up to 10 sensors in series to a<br />

single input on <strong>Pluto</strong> according to category 4.<br />

– to save on inputs!<br />

Dynamic signals<br />

1–10 doors with one Eden per door<br />

category 4<br />

<br />

<strong>Pluto</strong><br />

has inputs for static and<br />

dynamic sensors. Several<br />

sensors can be connected<br />

to one dynamic input in<br />

accordance with category 4.<br />

<strong>For</strong> example non-contact Eden sensors, Spot light beams<br />

and Tina emergency stop buttons can all be connected in<br />

series to a single <strong>Pluto</strong> input. Even mechanical switches can<br />

be connected to the 'dynamic' safety circuit using Jokab<br />

<br />

that can be used as both inputs and outputs.<br />

<br />

Dynamic signals<br />

1-10 sensors<br />

category 4<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

<br />

IO connections<br />

<br />

<br />

<br />

both input and output at the same time (e.g. for a reset button with lamp<br />

indication)<br />

input/output<br />

Two inputs<br />

Static inputs (mechanical switches)<br />

2 for each door = category 4<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:3<br />

13

<strong>Pluto</strong> with databus - an overview<br />

Profibus DP<br />

DeviceNet<br />

CANopen<br />

Ethernet<br />

<strong>Pluto</strong> B20<br />

20 I/O<br />

<br />

Patented<br />

HMI<br />

Gateway for two-way databus<br />

communication between <strong>Pluto</strong> and<br />

other control systems.<br />

4 independent<br />

failsafe safety outputs<br />

<strong>Pluto</strong> is an All-Master-System for dynamic and static safety circuits<br />

where the inputs and other information are shared on a databus.<br />

Several safety sensors can be connected to one input while still<br />

achieving the highest level of safety. There are also combined inputs<br />

and outputs that can be used, for example, for lamp pushbuttons<br />

where the input and output functions are used simultaneously.<br />

<strong>Pluto</strong> has inputs for all safety devices on the market, and the <strong>Pluto</strong><br />

Manager software selects how each input shall respond.<br />

HMI <br />

panel can communicate<br />

with <strong>Pluto</strong> in both directions.<br />

Connection can be<br />

made via the bus or direct<br />

to the front of the <strong>Pluto</strong>.<br />

<br />

<strong>Pluto</strong> bridge<br />

With a Gateway set up<br />

as a <strong>Pluto</strong> bridge, it is<br />

<br />

increase the databus<br />

length<br />

use different databus<br />

speeds for each section<br />

filter information from<br />

one section to reduce<br />

the databus loading on<br />

other sections.<br />

<strong>Pluto</strong> without a databus – A single <strong>Pluto</strong> can be used as a<br />

fully programmable safety logic controller.<br />

<strong>Pluto</strong> S20<br />

<strong>Pluto</strong> S46<br />

Connector expansion<br />

Patented Patented Patented<br />

Several expansion relays can be connected<br />

to a single <strong>Pluto</strong> safety output<br />

while retaining the safety level.<br />

<br />

words, they are similar to the equivalent versions with bus connections, the B20 and B46-6.<br />

2:4<br />

www.jokabsafety.com

1<br />

<strong>Pluto</strong> B46<br />

<strong>Pluto</strong> AS-i<br />

2<br />

46 I/O<br />

<strong>Safety</strong> Monitor/Master<br />

Safe bus<br />

12 I/O<br />

(A/D)<br />

+ 31 AS-i safety slaves<br />

3<br />

6 independent<br />

failsafe safety outputs<br />

Patented<br />

Patented<br />

4 independent<br />

failsafe safety outputs<br />

Approvals<br />

EN 954-1, Category 4<br />

EN ISO 13849-1, PL e<br />

EN 61496-1, Type 4<br />

EN 61508, SIL 3<br />

EN ISO 62061, SIL 3<br />

EN ISO 60204-1<br />

EN 50178<br />

EN ISO 574, Type lllc<br />

EN ISO 50295 (Only <strong>Pluto</strong> AS-i)<br />

4<br />

5<br />

Absolute encoder.<br />

8 single turn or multi<br />

turn absolute encoders<br />

can be connected directly<br />

to the safety bus.<br />

<strong>Pluto</strong> AS-i is an AS-i module which can be con-<br />

<br />

on the bus or work together with an AS-i master<br />

<br />

digital outputs, as well as safety outputs.<br />

6<br />

7<br />

Free software is available via our website, at<br />

www.jokabsafety.com!<br />

8<br />

9<br />

10<br />

<strong>Pluto</strong> Manager<br />

Programming is performed using ladder or<br />

Boolean algebra – with timers, auxiliary memory,<br />

registers, sequential programming and<br />

TÜV-approved function blocks. The program<br />

can be downloaded cost-free from the web<br />

site. Programs can be loaded via one <strong>Pluto</strong> to<br />

all the other <strong>Pluto</strong> units on the databus.<br />

11<br />

12<br />

www.jokabsafety.com 2:5<br />

13

I/O Overview - <strong>Pluto</strong><br />

IDFIX<br />

IDFIX<br />

<br />

<br />

<br />

<br />

<br />

only one input if Jokab <strong>Safety</strong> dynamic safety components are used.<br />

<br />

<br />

<br />

<br />

<br />

for electro-mechanical components such as contactors and valves.<br />

<br />

Failsafe relay outputs that are individually failsafe and individually programmable.<br />

2:6<br />

www.jokabsafety.com

Input connection<br />

<br />

short-circuits it is possible to use up to three different dynamic signals and static voltage (+24 V) to<br />

supply the inputs. The inputs are then programmed to only accept one of the signal types.<br />

<br />

thereby be able to detect a short-circuit between the channels.<br />

<br />

and the output of the sensor will be detected at the <strong>Pluto</strong> input. Category 4 can thus be achieved by using<br />

only one channel and one input.<br />

1<br />

2<br />

3<br />

Emergency<br />

stop with<br />

Tina<br />

Emergency<br />

stop with<br />

Tina<br />

Spot light<br />

beam<br />

Eden sensor<br />

4<br />

5<br />

6<br />

Two-channel system Single channel dynamic system, category 4<br />

<br />

Reset button that uses the combined input and output facility<br />

Resetting with a lamp<br />

input/output<br />

7<br />

8<br />

9<br />

(Current monitoring)<br />

24VDC<br />

<br />

A1<br />

X4<br />

10<br />

Both a lamp and a pushbutton can be connected to the same terminal. This function<br />

<br />

<br />

is intact. The lamp is only considered to be intact if sufficient current is being drawn from<br />

<br />

<br />

Examples of connector expansion<br />

11<br />

12<br />

www.jokabsafety.com 2:7<br />

13

Technical data - general<br />

<br />

<br />

<br />

Black and beige<br />

24V DC ±15%<br />

<br />

<br />

<br />

<br />

<br />

<br />

Cat. 4 in accordance with<br />

EN 954-1<br />

<br />

EN 61508/EN 62061<br />

Failsafe inputs I & IQ<br />

<br />

Current at 24 V<br />

Max. overvoltage<br />

Failsafe transistor outputs Q<br />

<br />

<br />

<br />

Failsafe relay outputs Q<br />

Max. voltage<br />

Max current<br />

Non-failsafe outputs Q<br />

<br />

<br />

Indication<br />

input/output LED<br />

<br />

<br />

also configurable as non-failsafe<br />

outputs<br />

5.1 mA<br />

<br />

–24 VDC<br />

Supply voltage - 1.5 V at 800 mA<br />

800 mA<br />

250 V AC<br />

1.5 A<br />

Transistor +24V, PNP "open<br />

collector" also configurable as<br />

failsafe inputs<br />

800 mA<br />

<br />

<br />

<strong>Pluto</strong> databus<br />

Max number of <strong>Pluto</strong> units on<br />

<br />

<br />

<br />

<br />

AS-i databus<br />

<br />

<br />

<br />

Temperature<br />

<br />

<br />

Response times<br />

Dyn. A or static input to relay<br />

<br />

Dyn. A or static input to<br />

<br />

Dyn. B or Dyn. C input to<br />

<br />

Dyn. B or Dyn. C input to<br />

<br />

Software setting "NoFilt".<br />

<br />

<br />

Additional Response times<br />

Databus between <strong>Pluto</strong> units<br />

Databus between <strong>Pluto</strong> units<br />

on error<br />

Enclosure classification<br />

<br />

<br />

<br />

CAN<br />

100, 125, 200, 250, 400, 500,<br />

800, 1000 kb/s<br />

Up to 600 m<br />

150 m at 400 kb/s<br />

M2<br />

<br />

Master<br />

<strong>Safety</strong> monitor<br />

<strong>Safety</strong> monitor & slave<br />

–10˚C to +50˚C<br />

–25˚C to +55˚C<br />

1<br />

2<br />

3<br />

The units are assembled with a gap of at least 5 mm.<br />

4<br />

5<br />

6<br />

The terminal blocks are detachable without needing to disconnect the wiring.<br />

7<br />

8<br />

<strong>Pluto</strong> S20<br />

20 I/O<br />

Non-<strong>Pluto</strong> databus<br />

<strong>Pluto</strong> B46-6<br />

46 I/O<br />

<strong>Pluto</strong> S46-6<br />

46 I/O<br />

Non-<strong>Pluto</strong> databus<br />

<strong>Pluto</strong> AS-i<br />

AS-i databus<br />

<br />

<br />

<br />

Max total load 2.5 A<br />

<br />

Max total load 2 A<br />

<br />

Max total load 2 A<br />

<br />

Max total load 2 A<br />

<br />

Max total load 2 A<br />

<br />

Max total load 2 A<br />

<br />

<br />

<br />

– – – –<br />

–<br />

<br />

–<br />

<br />

– – –<br />

<br />

100 mA 150 mA 150 mA 100 mA<br />

6 A 10A 10A 6 A<br />

45 x 84 x 118 mm 90 x 84 x 118 mm 90 x 84 x 118 mm 45 x 84 x 118 mm<br />

www.jokabsafety.com 2:9<br />

9<br />

10<br />

11<br />

12<br />

13

PLUTO ACCESSORIES<br />

Name Article no. Explanation<br />

Gate-P1<br />

<strong>Pluto</strong> Gateway<br />

Profibus<br />

<br />

Gateway for two-way communication between <strong>Pluto</strong> databus<br />

and Profibus.<br />

Gate-C1<br />

<strong>Pluto</strong> Gateway<br />

CANopen<br />

Gate-D1<br />

<strong>Pluto</strong> Gateway<br />

DeviceNet<br />

Gate-E1<br />

<strong>Pluto</strong> Gateway<br />

Ethernet<br />

<br />

<br />

<br />

Gateway for two-way communication between <strong>Pluto</strong> databus<br />

and CANopen.<br />

Gateway for two-way communication between <strong>Pluto</strong> databus<br />

and DeviceNet.<br />

Gateway for two-way communication between <strong>Pluto</strong> databus<br />

and Ethernet.<br />

IDFIX-R<br />

IDFIX-RW<br />

<br />

<br />

<br />

<br />

IDFIX-DATA<br />

<br />

R-120 Terminating resistor for <strong>Pluto</strong> databus.<br />

Operator's panel <br />

<br />

<br />

<br />

<br />

<strong>Pluto</strong> Manager Programming tool for <strong>Pluto</strong> including function blocks.<br />

Can be downloaded from www.jokabsafety.com<br />

<strong>Pluto</strong> programming<br />

cable<br />

<br />

<strong>For</strong> loading <strong>PLC</strong> programs and monitoring.<br />

Databus cable<br />

<br />

<br />

CAN-Bus cable yellow 2 x 0.50 mm ²<br />

CAN-Bus cable purple 2 x 0.50 mm ² halogen-free<br />

Absolute<br />

encoder<br />

Absolute<br />

encoder<br />

<br />

<br />

<br />

Absolute encoder model RSA 698 (multi turn)<br />

<br />

<br />

<br />

<br />

<br />

<strong>Pluto</strong> communications cable for operator's panel<br />

2:10<br />

www.jokabsafety.com

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:11<br />

13

<strong>Pluto</strong> Manager<br />

Programming a project<br />

Step 1<br />

Step 2<br />

Step 3<br />

Step by step<br />

Step 1<br />

I/O configuration<br />

The inputs and outputs are configured depending on what they are connected to, static or dynamic signals,<br />

inputs and/or outputs, etc.<br />

Step 2<br />

Defining variables<br />

<br />

databus communication (GM) and registers (R). The names of the variables can be changed as required<br />

instead of the default variable names used in the <strong>PLC</strong> program.<br />

Step 3<br />

Ladder programming<br />

The programming language used in <strong>Pluto</strong> contains function blocks, certified by TÜV Rheinland, with solutions<br />

for the most common safety functions. The function blocks can be used in conjunction with standard ladder<br />

instructions. The programming language has a full instruction repertoire, similar to standard <strong>PLC</strong>s on the<br />

market, including timers, arithmetic functions, sequential programming set, etc.<br />

2:12<br />

www.jokabsafety.com

List of standards and special function blocks for <strong>Pluto</strong> Manager<br />

The safety designer has complete freedom to program the safety functions or to use TÜV-approved pre-defined safety<br />

function blocks.<br />

Blocks in the standard library (func05):<br />

1. Two-channel function with input for start<br />

2. Two-channel function with test input<br />

<br />

<br />

reset indication.<br />

4. Two-channel function with simultaneous requirement.<br />

5. Single channel function with input for start.<br />

6. Single channel function with start and test inputs.<br />

<br />

8. Two-channel function with max. time limitation<br />

(equivalent to JSHT2). Time begins to count down<br />

when both inputs are activated.<br />

9. Two-channel function with max. time limitation<br />

(equivalent to JSHT2). Time begins to count down<br />

when one of the inputs is activated.<br />

10. Single channel pulse function, e.g. for timed reset.<br />

11. Two-channel pulse function, e.g. for timed reset.<br />

12. Two single channel bypass connection functions with<br />

max. time limiting.<br />

<br />

<br />

time limiting.<br />

14. Two-channel bypass connection function with max.<br />

time limiting and simultaneous requirement.<br />

15. Two-channel safety function with max. time<br />

limited bypass connection.<br />

16. Two-hand control.<br />

<br />

18. Counter which counts down from preset value to 0.<br />

<br />

<br />

<br />

<br />

power level in Watts.<br />

<br />

power level in Watts.<br />

24. Light curtain with single cycle operation.<br />

25. Light curtain with single cycle operation and reset<br />

selection.<br />

Internet support - <strong>Pluto</strong><br />

ers,<br />

offering continuously updated product support. The<br />

<br />

<br />

<br />

<br />

requirements<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

26. Multiplication.<br />

<br />

Other function blocks<br />

1. <strong>Safety</strong> absolute encoder.<br />

2. Electronic cam.<br />

<br />

Special function blocks:<br />

1. Program library with program block for eccentric<br />

shaft presses.<br />

2. Custom special blocks can be made available.<br />

Function block example<br />

TC1RTI<br />

Two-channel function with test and reset<br />

inputs, and reset indication.<br />

TC1RTI<br />

www.jokabsafety.com 2:13<br />

In1<br />

In2<br />

Q<br />

IndReset<br />

<br />

safety device outputs are connected.<br />

Test is a condition that must be true at the<br />

moment of switching on, and can be used<br />

for monitoring external components. Test<br />

Reset TCfault<br />

must be true before the Reset input closes,<br />

i.e. the function block cannot be initiated Test<br />

by Test.<br />

Reset is a supervised reset input and<br />

must be activated (positive flank) after the other inputs have<br />

activated for the function output to be activated.<br />

<br />

and flashes when the function block is ready for resetting.<br />

The TCfault output is activated in the case of a two-channel<br />

<br />

<br />

Description<br />

The function block acts as a conventional two-channel safety<br />

<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13

Use:<br />

<strong>Pluto</strong><br />

Gateway<br />

Bi-directional status information<br />

from the <strong>Pluto</strong> safety <strong>PLC</strong><br />

Profibus DP<br />

DeviceNet<br />

CANopen<br />

Ethernet<br />

Features:<br />

Two-way communication<br />

Built-in filter function, shared<br />

network<br />

<br />

Can be located anywhere in<br />

the databus<br />

Common interface with <strong>Pluto</strong><br />

Ready-made function blocks<br />

<strong>Pluto</strong> Gateway is a unit providing two-way communication<br />

between a <strong>Pluto</strong> safety <strong>PLC</strong> and other field buses. There<br />

<br />

GATE-P1 – Profibus-DP<br />

GATE-D1 – DeviceNet<br />

GATE-C1 – CANopen<br />

GATE-E1 <br />

<br />

rail, and can be connected anywhere in a <strong>Pluto</strong> databus.<br />

The unit has a common interface with <strong>Pluto</strong>, i.e. the same<br />

cabling, and the <strong>Pluto</strong> Manager PC program can be used<br />

for servicing and where necessary programming. Normal-<br />

<br />

which means that programming tools are not required to<br />

put the gateway itself into operation.<br />

<strong>For</strong> programming <strong>Pluto</strong> there are ready-made function<br />

blocks which, via a <strong>Pluto</strong> Gateway, send and receive data<br />

from the supervisory system.<br />

The GATE-D1 and GATE-C1 types, which use a CAN<br />

databus on both sides, can also usefully be used as CAN<br />

bridges where it is required to split a <strong>Pluto</strong> databus into<br />

several sections. This is particularly useful when long databus<br />

cables are needed. There is also a built-in filter function<br />

which makes it possible to block data that is not required<br />

for use on the other side of the bridge, which reduces the<br />

databus loading in the other sections and thereby permits<br />

longer databus cables.<br />

2:14<br />

www.jokabsafety.com

Gateway block schematic diagram - <strong>Pluto</strong> Gateway<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com<br />

2:15<br />

13

<strong>Pluto</strong> Gateway<br />

Profibus<br />

Profibus DP<br />

<br />

<strong>Pluto</strong> safety <strong>PLC</strong>.<br />

Data from <strong>Pluto</strong><br />

-<br />

<br />

-<br />

BUS modules in the gateway, one module for each <strong>Pluto</strong><br />

unit. Local data in <strong>Pluto</strong> units can be read by a "local data”<br />

module together with the <strong>PLC</strong> codes in the supervisory<br />

system.<br />

Data to <strong>Pluto</strong><br />

<br />

non-safety-related information to a <strong>Pluto</strong> safety <strong>PLC</strong>. A total<br />

of 64 Boolean values and 8 different 16-bit registers<br />

can be transmitted. Function blocks for these functions are<br />

available in <strong>Pluto</strong> Manager.<br />

<strong>PLC</strong> function blocks<br />

<br />

into the supervisory <strong>PLC</strong> system, Jokab <strong>Safety</strong> provides<br />

ready-made function blocks for several popular brands of<br />

<strong>PLC</strong>. The function blocks make it easier to receive and<br />

send information to the <strong>Pluto</strong> system. The function blocks<br />

are supplied as open units with full access for the customer<br />

to change and add functions. These function blocks can<br />

be obtained via the Jokab <strong>Safety</strong> web site.<br />

<strong>Pluto</strong> databus LED<br />

<br />

PC port<br />

Profibus LED<br />

Profibus connector<br />

2:16<br />

www.jokabsafety.com

Technical data - Gateway Profibus<br />

Manufacturer:<br />

<br />

1<br />

Article number/ordering data: GATE-P1<br />

Databuses:<br />

<strong>Pluto</strong> databus speeds:<br />

-<strong>Pluto</strong> databus CAN (isolated)<br />

<br />

100, 200, 250, 400, 500, 800 and<br />

1000 kbit/s<br />

(automatic speed detection)<br />

2<br />

PROFIBUS speed:<br />

PROFIBUS address:<br />

Up to 12 Mbit/s (automatic speed<br />

detection)<br />

<br />

3<br />

PROFIBUS version:<br />

DP slave, DP-V0<br />

Connections:<br />

<br />

(included)<br />

nection.<br />

Bottom, 2-pole terminal for 24 V DC<br />

(included)<br />

119 mm<br />

4<br />

Status indication:<br />

<strong>Pluto</strong> databus status indication via LED<br />

<br />

Operating voltage: 24 V DC, -15% till +20%<br />

Current at 24 V: < 100 mA (recommended fuse ≤6 A)<br />

5<br />

Dimensions (w x h x d):<br />

22.5 x 101 x 119 mm<br />

Installation:<br />

<br />

Operating temperature (ambient): -10°C to + 55ºC<br />

Temperature, transport and storage: -25°C to + 55ºC<br />

101 mm<br />

6<br />

Humidity:<br />

EN 60 204-1 50% at 40ºC (ambient<br />

90% at 20ºC)<br />

Enclosure classification:<br />

<br />

<br />

22,5 mm<br />

7<br />

Gateway block schematic diagram - <strong>Pluto</strong> Profibus<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com<br />

2:17<br />

13

<strong>Pluto</strong> Gateway<br />

DeviceNet<br />

DeviceNet<br />

<br />

with <strong>Pluto</strong> safety <strong>PLC</strong>.<br />

Data from <strong>Pluto</strong><br />

Via DeviceNet a supervisory <strong>PLC</strong> system can have access<br />

<br />

<br />

”implicit” messages. Local data in <strong>Pluto</strong> units can be read<br />

via DeviceNet ”explicit” messages.<br />

Data to <strong>Pluto</strong><br />

Via DeviceNet a supervisory <strong>PLC</strong> system can transmit nonsafety-related<br />

information to a <strong>Pluto</strong> safety <strong>PLC</strong>. A total of<br />

64 Boolean values and 8 different 16-bit registers can be<br />

transmitted (via DeviceNet ”implicit” or ”explicit” messages).<br />

Function blocks for these commands are available in<br />

<strong>Pluto</strong> Manager.<br />

<strong>Pluto</strong> bridge<br />

A GATE-D1 can also be used to advantage as a CAN<br />

bridge when it is required to divide a <strong>Pluto</strong> databus into<br />

several sections. This is particularly useful when long databus<br />

cables are needed.<br />

There is also a built-in filter function which makes it possible<br />

to block any data that is not required for use on the<br />

other side of the bridge, which reduces the databus loading<br />

in the other sections and thereby permits longer databus<br />

cables.<br />

ABB Robotics IRC5<br />

<br />

<br />

that describes this integration can be obtained via the Jokab<br />

<strong>Safety</strong> web site.<br />

<strong>Pluto</strong> databus LED<br />

<br />

PC port<br />

DeviceNet LED<br />

DeviceNet connector<br />

2:18<br />

www.jokabsafety.com

Technical data - DeviceNet<br />

Manufacturer<br />

<br />

1<br />

Article number/ordering data: GATE-D1<br />

Databuses:<br />

<strong>Pluto</strong> databus speeds:<br />

-<strong>Pluto</strong> databus CAN (isolated)<br />

-DeviceNet CAN (isolated)<br />

100, 200, 250, 400, 500, 800 and<br />

1000 kbit/s<br />

(automatic speed detection)<br />

2<br />

DeviceNet speeds:<br />

DeviceNet address:<br />

<br />

switch)<br />

<br />

3<br />

DeviceNet Version:<br />

<br />

Connections:<br />

<br />

(included)<br />

Front, 5-pole terminal for DeviceNet<br />

(included)<br />

Bottom, 2-pole terminal for 24 V DC<br />

(included)<br />

119 mm<br />

4<br />

Status indications:<br />

<strong>Pluto</strong> databus status indication via LED<br />

DeviceNet MNS status indication via<br />

LED<br />

Operating voltage: 24 V DC, -15% till +20%<br />

5<br />

Current at 24 V: < 100 mA (recommended fuse ≤6 A)<br />

Dimensions (w x h x d):<br />

22.5 x 101 x 119 mm<br />

Installation:<br />

<br />

Operating temperature (ambient): -10°C to + 55ºC<br />

Temperature,<br />

transport and storage: -25°C to + 55ºC<br />

101 mm<br />

6<br />

Humidity:<br />

Enclosure classification:<br />

EN 60 204-1 50% at 40ºC (ambient<br />

90% at 20ºC)<br />

<br />

<br />

22,5 mm<br />

7<br />

Gateway block schematic diagram - <strong>Pluto</strong> DeviceNet<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:19<br />

13

<strong>Pluto</strong> Gateway<br />

CANopen<br />

CANopen<br />

<br />

with <strong>Pluto</strong> safety <strong>PLC</strong>.<br />

Data from <strong>Pluto</strong><br />

Via CANopen a supervisory <strong>PLC</strong> system can have access<br />

<br />

<br />

<br />

<br />

the supervisory system.<br />

Data to <strong>Pluto</strong><br />

Via CANopen a supervisory <strong>PLC</strong> system can send nonsafety-related<br />

information to a <strong>Pluto</strong> safety <strong>PLC</strong>. A total of<br />

64 Boolean values and 8 different 16-bit registers can be<br />

<br />

blocks for these commands are available in <strong>Pluto</strong> Manager.<br />

<strong>Pluto</strong> bridge<br />

A GATE-C1 can also be used to advantage as a CAN<br />

bridge when it is required to divide a <strong>Pluto</strong> databus into<br />

several sections. This is particularly useful when long databus<br />

cables are needed.<br />

There is also a built-in filter function which makes it possible<br />

to block any data that is not required for use on the<br />

other side of the bridge, which reduces the databus loading<br />

in the other sections and thereby permits longer databus<br />

cables.<br />

<strong>Pluto</strong> databus LED<br />

<br />

PC port<br />

CANopen LED<br />

<br />

2:20<br />

www.jokabsafety.com

Technical data - Gateway CANopen<br />

Manufacturer<br />

<br />

1<br />

Article number/ordering data: GATE-C1<br />

Databuses:<br />

<strong>Pluto</strong> databus speeds:<br />

-<strong>Pluto</strong> databus CAN (isolated)<br />

-CANopen CAN (isolated)<br />

100, 200, 250, 400, 500, 800 and<br />

1000 kbit/s<br />

(automatic speed detection)<br />

2<br />

CANopen speeds:<br />

<br />

switch)<br />

10, 20, 50, 100, 125, 250, 500, 800<br />

and 1000 kbit/s (via software)<br />

3<br />

CANopen address:<br />

<br />

CANopen version:<br />

Connections:<br />

Status indications:<br />

”Version 4.02 of the CiA Draft Standard<br />

<br />

<br />

(included)<br />

Front, 5-pole terminal for CANopen<br />

(included)<br />

Bottom, 2-pole terminal for 24 V DC<br />

(included)<br />

<strong>Pluto</strong> databus status indication via LED<br />

CANopen status indication via LED<br />

119 mm<br />

4<br />

5<br />

Operating voltage: 24 V DC, -15% till +20%<br />

Current at 24 V: < 100 mA (recommended fuse ≤6 A)<br />

Dimensions (w x h x d):<br />

22.5 x 101 x 119 mm<br />

Installation:<br />

<br />

101 mm<br />

6<br />

Operating temperature (ambient): -10°C to + 55ºC<br />

Temperature, transport and storage: -25°C to + 55ºC<br />

Humidity:<br />

EN 60 204-1 50% at 40ºC (ambient<br />

90% at 20ºC)<br />

Enclosure classification:<br />

<br />

<br />

22,5 mm<br />

7<br />

Gateway block schematic diagram - <strong>Pluto</strong> CANopen<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com<br />

2:21<br />

13

<strong>Pluto</strong> Gateway<br />

Ethernet<br />

Ethernet<br />

cation<br />

with <strong>Pluto</strong> safety <strong>PLC</strong>.<br />

Protocol<br />

<br />

from and to <strong>Pluto</strong> safety <strong>PLC</strong>s via Ethernet protocols Eth-<br />

<br />

<br />

<br />

server and a terminal server.<br />

Data from <strong>Pluto</strong><br />

Via one of the Ethernet protocols a supervisory <strong>PLC</strong> system<br />

<br />

-<br />

<br />

Local data in <strong>Pluto</strong> units can be read by special commands<br />

together with the <strong>PLC</strong> codes in the supervisory system.<br />

Data to <strong>Pluto</strong><br />

Via the Ethernet protocol a supervisory <strong>PLC</strong> system can<br />

transmit non-safety-related information to a <strong>Pluto</strong> safety<br />

<strong>PLC</strong>. A total of 64 Boolean values and 8 different 16-bit<br />

registers can be transmitted. Function blocks for these<br />

functions are available in <strong>Pluto</strong> Manager.<br />

<strong>Pluto</strong> databus LED<br />

<br />

PC port<br />

Ethernet LED<br />

Ethernet connector<br />

2:22<br />

www.jokabsafety.com

C L<br />

IQ12<br />

C H I1 I3<br />

I0<br />

IQ14<br />

I2<br />

IQ16<br />

I4<br />

I5 I7 IQ11 Q3<br />

Q0<br />

IQ10<br />

Q1<br />

IQ13 IQ15 IQ17 ID 0V +24V<br />

I6<br />

Q2<br />

C L<br />

IQ12<br />

C H I1 I3<br />

I0<br />

IQ14<br />

I2<br />

IQ16<br />

I4<br />

I5 I7 IQ11 Q3<br />

Q0<br />

IQ10<br />

Q1<br />

IQ13 IQ15 IQ17 ID 0V +24V<br />

I6<br />

Q2<br />

PLUTO<br />

BUS<br />

K<br />

PR<br />

Mod<br />

Status<br />

Net<br />

Status<br />

C L<br />

IQ12<br />

C H I1 I3<br />

I0<br />

IQ14<br />

I2<br />

IQ16<br />

I4<br />

I5 I7 IQ11 Q3<br />

Q0<br />

IQ10<br />

Q1<br />

IQ13 IQ15 IQ17 ID 0V +24V<br />

I6<br />

Q2<br />

Technical data - Ethernet<br />

Manufacturer<br />

<br />

Article number/<br />

ordering data: GATE-E1<br />

<strong>Pluto</strong> databus<br />

CAN (isolated)<br />

<strong>Pluto</strong> databus speeds 100, 200, 250, 400, 500, 800<br />

and 1000 kbit/s<br />

(automatic speed detection)<br />

Ethernet<br />

10/100 Mbit/s<br />

Half and full duplex<br />

Ethernet protocol<br />

Status from and to <strong>Pluto</strong> safety<br />

<strong>PLC</strong><br />

<br />

<br />

- Modbus TCP<br />

<br />

EtherNet/IP<br />

PROFINET<br />

Modbus TCP<br />

Binary server (TCP/IP)<br />

Web server<br />

Note that certain combinations<br />

of server protocols cannot be<br />

used simultaneously.<br />

<br />

configuration<br />

- Web server<br />

<br />

<br />

<br />

<br />

<br />

<br />

According to the Modbus organisation,<br />

version 1.0b (approx. 20<br />

messages per second).<br />

<br />

status from/to the <strong>Pluto</strong> system.<br />

<br />

addresses.<br />

Terminal server (TCP/IP) Simple server with the same<br />

commands as via the serial programming<br />

port in the unit.<br />

IP address<br />

Static sharing via web server or<br />

via programming port.<br />

Gateway configuration <br />

<br />

<br />

Connections<br />

<br />

databus (included)<br />

Front, Ethernet connection via<br />

RJ-45 (screened cable cat. 5e<br />

FTP)<br />

Bottom, 2-pole terminal for 24 V<br />

DC (included)<br />

Status indications<br />

<strong>Pluto</strong> databus status indication<br />

via LED (<strong>Pluto</strong> databus)<br />

Ethernet module status indication<br />

via LED (Mod Status)<br />

Ethernet network status indication<br />

via LED (Net Status)<br />

Operating voltage 24 V DC, -15 % till +20 %<br />

Current at 24 V<br />

< 150 mA (recommended fuse<br />

≤6 A)<br />

Dimensions (w x h x d): <br />

Installation<br />

<br />

Operating temperature<br />

(ambient) -10°C to + 55ºC<br />

Temperature,<br />

transport and storage -25°C to + 55ºC<br />

Humidity EN 60 204-1 50 % at 40ºC<br />

(ambient 90 % at 20ºC)<br />

Enclosure classification <br />

<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

Gateway block schematic diagram - <strong>Pluto</strong> Ethernet<br />

<strong>PLC</strong><br />

Ethernet, non safety<br />

119 mm<br />

9<br />

GATE-E1<br />

10<br />

Modbus TCP<br />

EtherNet/IP<br />

PROFINET<br />

<strong>Pluto</strong> CAN bus, safety<br />

Gateway<br />

101 mm<br />

11<br />

12<br />

<br />

<strong>Pluto</strong> <strong>Pluto</strong> <strong>Pluto</strong><br />

www.jokabsafety.com 2:23<br />

13

<strong>Pluto</strong><br />

Safe Encoder<br />

Use:<br />

Safe position and speed determination<br />

of machine movements.<br />

Features:<br />

High resolution<br />

Selectable resolution<br />

Connected directly to the <strong>Pluto</strong><br />

databus<br />

Ready-made function blocks<br />

Rotational absolute value sensor for safe<br />

positioning<br />

Together with a <strong>Pluto</strong> safety <strong>PLC</strong>, this rotational absolute<br />

encoder can be used for safe position determination. This<br />

is particularly useful in the case of such equipment as gantry<br />

robots, industrial robots, etc. Also in eccentric shaft<br />

presses, existing cam mechanisms can be replaced by absolute<br />

value position sensors for safe positioning. The sensors<br />

are available in single and multi-turn versions.<br />

Up to 16 absolute encoders can be connected to a <strong>Pluto</strong><br />

CAN databus. A <strong>Pluto</strong> on the databus reads the sensor<br />

values, which are evaluated. With a special function block<br />

in the <strong>PLC</strong> code, it is possible to design two-channel solutions<br />

with the sensors. The user can obtain safe values for<br />

position and speed from these values. This enables supervision<br />

of stationary and overspeed conditions.<br />

The absolute value sensors are standard sensors with<br />

modified software to meet the safety requirements.<br />

Example of an application where 2 sensors provide safe position determination in a gantry robot.<br />

2:24<br />

www.jokabsafety.com

Technical data – Safe Encoder RSA 597<br />

Manufacturer<br />

<br />

Article number/ordering data: <br />

Ambient temperature<br />

<br />

Temperature, transport and storage <br />

Ingress protection class<br />

<br />

At shaft inlet<br />

<br />

Vibration (55 to 2000 Hz)<br />

2 <br />

60068-2-6<br />

Shock (6ms)<br />

< 2,000 m/s 2 <br />

<br />

Material, enclosure<br />

Aluminium<br />

Surface treatment<br />

Painted and chromed or anodised<br />

Weight<br />

<br />

Accuracy and resolution<br />

Resolution<br />

<br />

Accuracy<br />

± ½ LSB (Least Significant Bit)<br />

Operating voltage<br />

<br />

Polarity-protected<br />

<br />

Short-circuit protected<br />

<br />

Databus speed<br />

5 kbit/s - 1 Mbit/s, preset at 500kbit/s<br />

Address input<br />

Active low<br />

Code type<br />

Binary<br />

Programmable functions<br />

Resolution, 0 position<br />

Direction, Databus speed<br />

Current consumption<br />

50 mA at 24V dc<br />

Max current consumption<br />

100 mA<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:25<br />

13

Technical data – Safe Encoder RSA 698<br />

Manufacturer<br />

<br />

Article number/ordering data: <br />

Ambient temperature<br />

<br />

Temperature, transport and storage <br />

Ingress protection class<br />

<br />

At shaft inlet<br />

<br />

Vibration (55 to 2000 Hz)<br />

< 100 m/s 2 <br />

60068-2-6<br />

Shock (6ms)<br />

< 2,000 m/s 2 <br />

<br />

Material, enclosure<br />

Aluminium<br />

Surface treatment<br />

Anodised<br />

Weight<br />

Approx. 400g<br />

Accuracy and resolution<br />

Resolution, total<br />

25 bit<br />

<br />

12 bits, 4096 rotations<br />

Accuracy<br />

± 1 LSB (Least Significant Bit)<br />

Operating voltage<br />

<br />

Polarity-protected<br />

<br />

Short-circuit protected<br />

<br />

Databus speed<br />

10 kbit/s - 1 Mbit/s<br />

Code type<br />

Binary<br />

Programmable functions<br />

Resolution, 0 position<br />

Current consumption<br />

50 mA at 24V dc<br />

Max current consumption<br />

100 mA<br />

2:26<br />

www.jokabsafety.com

Safe Encoder<br />

Function block for a single-turn encoder<br />

that generates safe position and speed<br />

values from two absolute encoders.<br />

Function<br />

The block reads and evaluates one absolute<br />

encoders. The position value is sent to<br />

the 'Position' output. The 'Speed' output<br />

is the average value for the speed, at the<br />

<br />

<br />

applications the values of 'Position' and<br />

'Speed' are used in conjunction with the<br />

<br />

Descriptions of inputs and outputs<br />

<br />

<br />

<br />

(max 2% of Range)<br />

<br />

<br />

the position values are within the margin set by 'MaxDiff'<br />

<br />

<br />

<br />

<br />

NOTE! Position values from single encoders are only available<br />

<br />

NOTE! <br />

<br />

1<br />

2<br />

3<br />

4<br />

Safe Encoder<br />

Multiturn<br />

Function block for a multi-turn encoder<br />

that generates safe position and speed<br />

values from two absolute encoders.<br />

Operative system 2.4.4 or higher is<br />

required.<br />

Function<br />

The block reads and evaluates two<br />

absolute encoders. The average value for<br />

the two sensors is calculated and sent to<br />

the 'Position' output. The 'Speed' output<br />

is the average value for the speed, at the<br />

rate of pulses/10 ms. The block monitors<br />

that the encoder position values do not<br />

differ by more than the input value set by<br />

-<br />

<br />

the values of 'Position' and 'Speed' are<br />

<br />

Encoder Cam<br />

Function block for electronic cam gear.<br />

Function<br />

<br />

input register 'PosReg' is within the limits<br />

for ’MinPos’ and ’MaxPos’.<br />

<br />

that defines the sensor's zero position.<br />

Position

Example – Robot cell with <strong>Pluto</strong><br />

Description:<br />

The example describes a processing machine served by<br />

a robot. The machine safety system consists of one <strong>Pluto</strong><br />

to which all protection has been connected. The robot has<br />

been equipped with a <strong>Pluto</strong> to which the cell protection<br />

has been connected. The <strong>Pluto</strong> for the machine has been<br />

connected via a databus cable to the robot's <strong>Pluto</strong> so that<br />

common functions, such as emergency stop, can be used<br />

by the whole cell.<br />

Function:<br />

Emergency stop takes priority and will stop both the machine<br />

and the robot. The machine hatch acts as the zone<br />

divider, when the hatch is closed the machine forms one<br />

zone and the robot another zone. When the machine hatch<br />

is open, both the machine and the robot belong to the<br />

<br />

is open, the machine and the robot will both stop, but if the<br />

machine hatch is closed, only the robot will be stopped.<br />

After the door has been opened, the system must be reset<br />

by means of the reset button on the outside of the door.<br />

Emergency stop is reset when the pressed-in button is<br />

ever<br />

start immediately on resetting the emergency stop or<br />

the door.<br />

2:28<br />

www.jokabsafety.com

Electrical connections<br />

1<br />

Apparatus<br />

enclosure<br />

Robot<br />

enclosure<br />

<strong>Pluto</strong> databus<br />

Electrical equipment<br />

enclosure for machinery<br />

2<br />

Emergency stop<br />

Door<br />

Emergency stop<br />

Machine<br />

emergency<br />

stop<br />

<strong>Safety</strong> interlock switch<br />

3<br />

Machine<br />

protective<br />

stop<br />

4<br />

Robot<br />

Emergency stop<br />

Robot<br />

Autostop<br />

5<br />

<br />

<br />

<br />

Matning<br />

<br />

<br />

Supply<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:29<br />

13

<strong>Pluto</strong> 0 settings<br />

<strong>Pluto</strong> 0<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

2:30<br />

www.jokabsafety.com

<strong>Pluto</strong> 1 settings<br />

1<br />

<strong>Pluto</strong> 1<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

the machine hatch.<br />

<br />

<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:31<br />

13

<strong>PLC</strong> code <strong>Pluto</strong> 0<br />

1<br />

Start<br />

2<br />

Two-channel supervision with automatic reset emergency stop at the door.<br />

<br />

<br />

In1<br />

TC1S<br />

Q<br />

<br />

<br />

E-stop_kanal_2<br />

<br />

In2<br />

Start<br />

GM0.1 = E-stop_OK_mem<br />

Auxiliary memory for emergency stop OK<br />

I0.0 = E-stop_kanal_1 Channel 1 from the emergency stop button<br />

I0.1 = E-stop_kanal_2 Channel 2 from the emergency stop button<br />

3<br />

Emergency stop for the robot<br />

When the emergency stop is activated, the robot will perform an emergency stop.<br />

To reset the safety features, the emergency stop button must be reset.<br />

<br />

<br />

<br />

GM0.1 = E-stop_OK_mem<br />

Auxiliary memory for emergency stop OK<br />

GM1.1 = E-stop_machine_OK_mem Global auxiliary memory from two-channel supervision of the emergency stop on the machine.<br />

Q0.3 = Robot_NS_OK Emergency stop for the robot<br />

4<br />

Automatic stop for the robot<br />

When the door of the cell opens the robot is set to automatically stop.<br />

To reset the safety features, the door must be closed and then the reset signal given.<br />

<br />

<br />

In1<br />

ResetT<br />

Q<br />

<br />

<br />

Reset<br />

<br />

Reset<br />

IndReset<br />

Reset_ind_1_mem<br />

<br />

Test<br />

.2 = Door<br />

Signal from the door sensor<br />

I1.15 = Reset Reset button Reset<br />

M0.0 = Reset_ind_1_mem Auxiliary memory for indication in the reset button<br />

Q0.2 = Robot_Autostopp_OK Automatic stop for the robot<br />

5<br />

<br />

Summary of local memories that shall generate the signal in the reset lamp.<br />

The global memory is then used in the <strong>Pluto</strong> where the output is.<br />

Reset_ind_1_mem<br />

Reset_ind_1_mem<br />

M0.0 GM0.0<br />

GM0.0 = Reset_ind_mem<br />

Collective memory for indication in the reset button<br />

M0.0 = Reset_ind_1_mem Auxiliary memory 1 for indication in the reset button<br />

2:32<br />

www.jokabsafety.com

6<br />

<br />

<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

<br />

<br />

<br />

GM1.0 = Machine hatch_OK_mem Global auxiliary memory from two-channel supervision of the safety interlock switch in the machine hatch.<br />

SR0.10 = SR_<strong>Pluto</strong>Display <strong>Pluto</strong> display figure<br />

SR0.11 = SR_ErrorCode Error code. <strong>For</strong> user error 200 + no<br />

1<br />

2<br />

3<br />

7<br />

8<br />

<br />

Alarm 02 – Door open.<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

Door SR_ErrorCode = 0 SR_<strong>Pluto</strong>Display = 202<br />

<br />

10.2 = Door Signal from the door sensor<br />

SR0.10 = SR_<strong>Pluto</strong>Display<br />

<strong>Pluto</strong> display figure<br />

SR0.11 = SR_Errorcode<br />

Error code. <strong>For</strong> user error 200 + no<br />

<br />

Alarm 01 - Emergency stop activated<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

<br />

SR0.11 = 0 SR0.10 = 201<br />

4<br />

5<br />

6<br />

7<br />

GM0.1 = E-stop_OK_mem<br />

SR0.10 = SR_<strong>Pluto</strong>Display<br />

SR0.11 = SR_ErrorCode<br />

Auxiliary memory for emergency stop OK<br />

<strong>Pluto</strong> display figure<br />

Error code. <strong>For</strong> user error 200 + no<br />

8<br />

9<br />

10<br />

11<br />

12<br />

www.jokabsafety.com 2:33<br />

13

<strong>PLC</strong> code <strong>Pluto</strong> 1<br />

1<br />

Start<br />

2<br />

Two-channel supervision with automatic reset of the emergency stop on the machine.<br />

<br />

<br />

In1<br />

TC1S<br />

<br />

<br />

E-stop_machine_kanal_2<br />

<br />

In2<br />

Start<br />

GM1.1 = E-stop_machine_OK_mem Global auxiliary memory from two-channel supervision of the emergency stop on the machine.<br />

I0.0 = E-stop_machine_kanal_1 Channel 1 from the emergency stop button on the machine<br />

I0.1 = E-stop_machine_kanal_2 Channel 2 from the emergency stop button on the machine<br />

3<br />

Two-channel supervision of the machine hatch switch.<br />

The switch has alternating contacts and the variable name shows the contact arrangement for the respect signals when the key is in the sensor.<br />

- Machine hatch_NC gives a signal<br />

<br />

<br />

<br />

<br />

<br />

In1<br />

TC1S<br />

Q<br />

<br />

<br />

In2<br />

Start<br />

GM1.0 = Machine hatch_OK_mem Global auxiliary memory from two-channel supervision of the safety interlock switch in the machine hatch.<br />

I1.11 = Machine hatch_NC Channel 1 from the safety interlock switch<br />

I1.12 = Machine hatch_NO Channel 2 from the safety interlock switch<br />

4<br />

Emergency machine stop.<br />

When the emergency stop is activated, the machine will perform an emergency stop.<br />

To reset the safety features, the emergency stop button must be reset.<br />

<br />

<br />

<br />

GM0.1 = E-stop_OK_mem<br />

Auxiliary memory for emergency stop OK<br />

GM1.1 = E-stop_machine_OK_mem Global auxiliary memory from two-channel supervision of the emergency stop on the machine.<br />

Q1.0 = Maskin_E-stop_OK Emergency machine stop.<br />

5<br />

Protective machine stop.<br />

When the protective stop is activated, the machine will stop.<br />

<br />

To reset the safety features, the door or the machine hatch must be closed and then the reset signal given.<br />

<br />

<br />

In1<br />

ResetT<br />

Q<br />

<br />

<br />

Door<br />

<br />

IndReset<br />

Reset_ind_2_mem<br />

<br />

Reset<br />

<br />

Reset<br />

Test<br />

2:34<br />

www.jokabsafety.com

6<br />

GM1.0 = Machine hatch_OK_mem Global auxiliary memory from two-channel supervision of the safety interlock switch in the machine hatch.<br />

I0.2 = Door Signal from the door sensor<br />

I1.15 = Reset Reset button Reset<br />

M1.0 = Reset_Ind_2_mem Auxiliary memory 2 for indication in the reset button<br />

Q1.1 = Maskin_skyddstop_OK Protective machine stop.<br />

<br />

Summary of memories that shall generate the signal in the reset lamp.<br />

<br />

<br />

<br />

M1.0<br />

GM0.0 = Reset_Ind_mem<br />

Collective memory for indication in the reset button<br />

M1.0 = Reset_Ind_2_mem Auxiliary memory 2 for indication in the reset button<br />

Q1.15 = Reset_Ind Indication lamp in the reset button.<br />

<br />

<br />

1<br />

2<br />

3<br />

4<br />

7<br />

8<br />

9<br />

<br />

<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

<br />

<br />

GM1.0 = Machine hatch_OK_mem Global auxiliary memory from two-channel supervision of the safety interlock switch in the machine hatch.<br />

SR1.10 = SR_<strong>Pluto</strong>Display <strong>Pluto</strong> display figure<br />

SR1.11 = SR_ErrorCode Error code. <strong>For</strong> user error 200 + no<br />

<br />

Alarm 02 – Door open.<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

Door SR_ErrorCode = 0 SR_<strong>Pluto</strong>Display = 202<br />

<br />

I0.1 = Door Signal from the door sensor<br />

SR1.10 = SR_<strong>Pluto</strong>Display<br />

<strong>Pluto</strong> display figure<br />

SR1.11 = SR_ErrorCode<br />

Error code. <strong>For</strong> user error 200 + no<br />

<br />

Alarm 01 - Emergency stop activated.<br />

To generate an alarm, a UE code (UE = User Error) can be shown on the <strong>Pluto</strong>'s display.<br />

This alarm code is selected by a value of between 200 and 299 being written into the <strong>Pluto</strong>'s display register.<br />

SR_ErrorCode = 0 is used as a condition to prioritise an internal alarm from the unit.<br />

<br />

SR1.11 = 0 SR1.10 = 201<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

GM0.1 = E-stop_OK_mem<br />

SR1.10 = SR_<strong>Pluto</strong>Display<br />

SR1.11 = SR_ErrorCode<br />

Auxiliary memory for emergency stop OK<br />

<strong>Pluto</strong> display figure<br />

Error code. <strong>For</strong> user error 200 + no<br />

12<br />

www.jokabsafety.com 2:35<br />

13