DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PART 1-2 -THUNDERBIRD 352 SPECIAL V-8 1-29<br />

ToolT53L300-A<br />

Tool1009<br />

ToolT58P-6000A<br />

1727-<br />

1728-A<br />

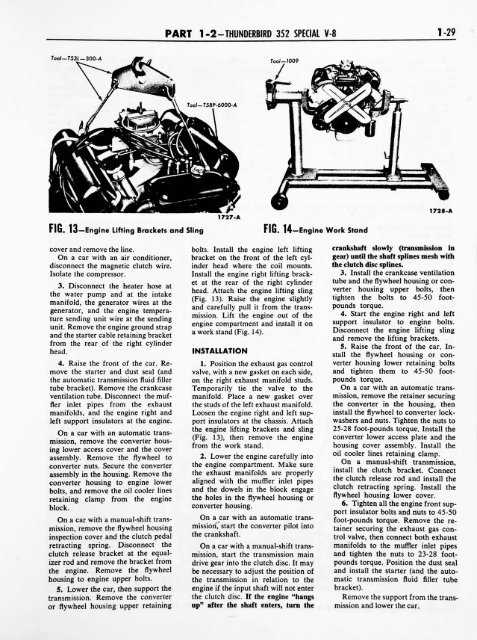

Fib. 13 Engine Lifting Brackets and Sling<br />

FIG. 14 Engine Work Stand<br />

cover and remove the line.<br />

On a car with an air conditioner,<br />

disconnect the magnetic clutch wire.<br />

Isolate the <strong>com</strong>pressor.<br />

3. Disconnect the heater hose at<br />

the water pump<br />

and at the intake<br />

manifold, the generator wires at the<br />

generator, and the engine tempera<br />

ture sending unit wire at the sending<br />

unit. Remove the engine ground strap<br />

and the starter cable retaining bracket<br />

from the rear of the right cylinder<br />

head.<br />

4. Raise the front of the car. Re<br />

move the starter and dust seal (and<br />

the automatic transmission fluid filler<br />

tube bracket). Remove the crankcase<br />

ventilation tube. Disconnect the muf<br />

fler inlet pipes from the exhaust<br />

manifolds, and the engine right and<br />

left support insulators at the engine.<br />

On a car with an automatic trans<br />

mission, remove the converter hous<br />

lower access cover and the cover<br />

ing<br />

assembly. Remove the flywheel to<br />

converter nuts. Secure the converter<br />

assembly in the housing. Remove the<br />

converter housing to engine lower<br />

bolts, and remove the oil cooler lines<br />

retaining clamp from the engine<br />

block.<br />

On a car with a manual-shift trans<br />

mission, remove the flywheel housing<br />

inspection cover and the clutch pedal<br />

retracting<br />

spring. Disconnect the<br />

clutch release bracket at the equal<br />

izer rod and remove the bracket from<br />

the engine. Remove the flywheel<br />

housing to engine upper bolts.<br />

5. Lower the car, then support the<br />

transmission. Remove the converter<br />

or flywheel housing upper retaining<br />

bolts. Install the engine left lifting<br />

bracket on the front of the left cyl<br />

inder head where the coil mounts.<br />

Install the engine right lifting brack<br />

et at the rear of the right cylinder<br />

head. Attach the engine lifting sling<br />

(Fig. 13). Raise the engine slightly<br />

and carefully pull it from the trans<br />

mission. Lift the engine out of the<br />

engine <strong>com</strong>partment and install it on<br />

a work stand (Fig. 14).<br />

INSTALLATION<br />

1. Position the exhaust gas control<br />

valve, with a new gasket on each side,<br />

on the right exhaust manifold studs.<br />

Temporarily tie the valve to the<br />

manifold. Place a new gasket over<br />

the studs of the left exhaust manifold.<br />

Loosen the engine right and left sup<br />

port insulators at the chassis. Attach<br />

the engine lifting brackets and sling<br />

(Fig. 13), then remove the engine<br />

from the work stand.<br />

2. Lower the engine carefully into<br />

the engine <strong>com</strong>partment. Make sure<br />

the exhaust manifolds are properly<br />

aligned with the muffler inlet pipes<br />

and the dowels in the block engage<br />

the holes in the flywheel housing or<br />

converter housing.<br />

On a car with an automatic trans<br />

the crankshaft.<br />

start the converter pilot into<br />

On a car with a manual-shift trans<br />

mission, start the transmission main<br />

drive gear into the clutch disc. It may<br />

be necessary to adjust the position of<br />

the transmission in relation to the<br />

engine if the input shaft will not enter<br />

the clutch disc. If the engine "hangs<br />

up"<br />

after the shaft enters, turn the<br />

crankshaft slowly<br />

(transmission in<br />

gear) until the shaft splines mesh with<br />

the clutch disc splines.<br />

3. Install the crankcase ventilation<br />

tube and the flywheel housing or con<br />

verter housing upper bolts, then<br />

tighten the bolts to 45-50 foot<br />

pounds torque.<br />

4. Start the engine right and left<br />

support insulator to engine bolts.<br />

Disconnect the engine lifting sling<br />

and remove the lifting brackets.<br />

5. Raise the front of the car. In<br />

stall the flywheel housing or con<br />

verter housing lower retaining bolts<br />

and tighten them to 45-50 foot<br />

pounds torque.<br />

On a car with an automatic trans<br />

mission, remove the retainer securing<br />

the converter in the housing, then<br />

install the flywheel to converter lock<br />

washers and nuts. Tighten the nuts to<br />

25-28 foot-pounds torque. Install the<br />

converter lower access plate and the<br />

housing<br />

cover assembly. Install the<br />

oil cooler lines retaining clamp.<br />

On a manual-shift transmission,<br />

install the clutch bracket. Connect<br />

the clutch release rod and install the<br />

clutch retracting<br />

spring. Install the<br />

flywheel housing lower cover.<br />

6. Tighten all the engine front sup<br />

port insulator bolts and nuts to 45-50<br />

foot-pounds torque. Remove the re<br />

tainer securing the exhaust gas con<br />

trol valve, then connect both exhaust<br />

manifolds to the muffler inlet pipes<br />

and tighten the nuts to 23-28 foot<br />

pounds torque. Position the dust seal<br />

and install the starter (and the auto<br />

matic transmission fluid filler tube<br />

bracket).<br />

Remove the support from the trans<br />

mission and lower the car.