DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

DEMO - 1959 Ford Thunderbird Shop Manual - ForelPublishing.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PART 1-2 -THUNDERBIRD 352 SPECIAL V-8 1-35<br />

ToolT52P-6135-DAD<br />

installation in the same cylin<br />

der from which they<br />

2. Remove the piston rings. Re<br />

were removed.<br />

move the piston pin retainers, then<br />

drive the pin out of the piston and<br />

connecting rod (Fig. 28). Discard the<br />

retainers.<br />

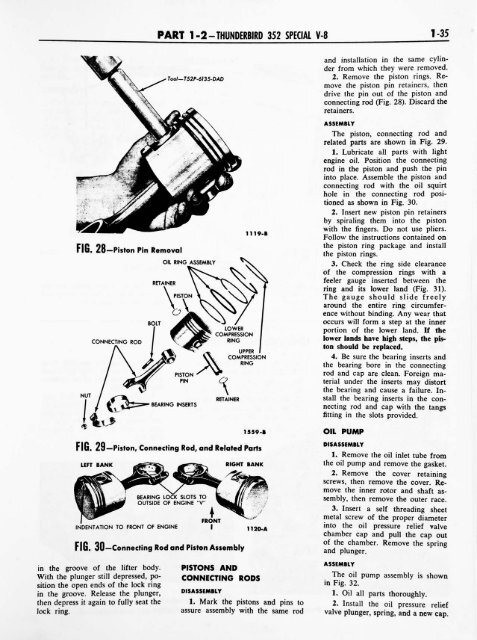

FIG. 28 Piston Pin Removal<br />

CONNECTING ROD<br />

OIL RING ASSEMBLY<br />

1119-B<br />

ASSEMBLY<br />

The piston, connecting rod and<br />

related parts are shown in Fig. 29.<br />

1. Lubricate all parts with light<br />

engine oil. Position the connecting<br />

rod in the piston and push the pin<br />

into place. Assemble the piston and<br />

connecting rod with the oil squirt<br />

hole in the connecting rod posi<br />

tioned as shown in Fig. 30.<br />

2. Insert new piston pin retainers<br />

by spiraling them<br />

into the piston<br />

with the fingers. Do not use pliers.<br />

Follow the instructions contained on<br />

the piston ring<br />

the piston rings.<br />

3. Check the ring<br />

package and install<br />

side clearance<br />

of the <strong>com</strong>pression rings with a<br />

feeler gauge inserted between the<br />

ring and its lower land (Fig. 31).<br />

The gauge should slide freely<br />

around the entire ring circumfer<br />

ence without binding. Any wear that<br />

occurs will form a step at the inner<br />

portion of the lower land. If the<br />

lower lands have high steps, the pis<br />

ton should be replaced.<br />

4. Be sure the bearing inserts and<br />

the bearing bore in the connecting<br />

NUT<br />

BEARING INSERTS<br />

RETAINER<br />

rod and cap<br />

are clean. Foreign ma<br />

terial under the inserts may distort<br />

the bearing and cause a failure. In<br />

stall the bearing inserts in the con<br />

necting rod and cap<br />

with the tangs<br />

fitting in the slots provided.<br />

1559-B<br />

FIG. 29 Piston, Connecting Rod, and Related Parts<br />

LEFT BANK RIGHT BANK<br />

OIL PUMP<br />

DISASSEMBLY<br />

1. Remove the oil inlet tube from<br />

the oil pump and remove the gasket.<br />

2. Remove the cover retaining<br />

screws, then remove the cover. Re<br />

BEARING LOCK SLOTS TO<br />

OUTSIDE OF ENGINE "V"<br />

INDENTATION TO FRONT OF ENGINE<br />

?<br />

FRONT<br />

I 11 20-A<br />

FIG. 30 Connecting Rod and Piston Assembly<br />

move the inner rotor and shaft as<br />

sembly, then remove the outer race.<br />

3. Insert a self<br />

threading sheet<br />

metal screw of the proper diameter<br />

into the oil pressure relief valve<br />

chamber cap and pull the cap out<br />

of the chamber. Remove the spring<br />

and plunger.<br />

in the groove of the lifter body.<br />

With the plunger still depressed, po<br />

sition the open ends of the lock ring<br />

in the groove. Release the plunger,<br />

then depress it again to fully<br />

seat the<br />

Jock ring.<br />

PISTONS AND<br />

CONNECTING RODS<br />

DISASSEMBLY<br />

1. Mark the pistons and pins to<br />

assure<br />

assembly<br />

with the same rod<br />

and<br />

ASSEMBLY<br />

The oil<br />

pump assembly is shown<br />

in Fig. 32.<br />

1. Oil all parts thoroughly.<br />

2. Install the oil pressure relief<br />

valve plunger, spring, and a new cap.