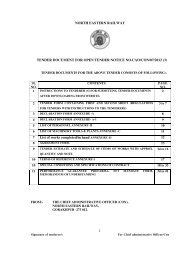

Design, Supply, Transportation, Erection at site, Commissioning

Design, Supply, Transportation, Erection at site, Commissioning

Design, Supply, Transportation, Erection at site, Commissioning

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.1 Loco maintenance Bays<br />

Page 14 of 34<br />

Pollutants consist of w<strong>at</strong>er, HSD, lubric<strong>at</strong>ing oil, grease dirt, radi<strong>at</strong>or coolants, sludge<br />

and certain chemicals. (CARDIUM & SEWAGE)<br />

1.2 Car body filter cleaning plants<br />

Pollutant discharged consists of lubric<strong>at</strong>ing oil, dirt and cleaning agents etc.<br />

1.3 Loco Components cleaning plants<br />

Pollutants discharge consists of oil, cleaning agents, sludge, dirt, metallic corroded<br />

metal flakes etc.<br />

1.4 Loco Washing<br />

Pollutant consists of detergent solution, oil, grease, dirt, lubric<strong>at</strong>ing oil sludge etc.<br />

1.5 Load Box<br />

Pollutants mainly consist of w<strong>at</strong>er, sludge, oil etc.<br />

1.6 Office Block / Canteen / DM Plant / Compressor<br />

Pollutants mainly w<strong>at</strong>er, sludge, oil, sewage sludge etc. including some chemicals.<br />

1.6.1 Discharge from Labor<strong>at</strong>ory<br />

Miscellaneous Lab chemicals, oil etc discharge in small quantities as pollutants.<br />

The contractor must ensure suitable provision of collecting effluent from<br />

different identified sources. It may necessit<strong>at</strong>e repair, extension of the existing drainage<br />

system etc.<br />

2. Setting up required effluent system :<br />

The effluent tre<strong>at</strong>ment system is expected to tre<strong>at</strong> an estim<strong>at</strong>ed 100 KL of<br />

pollutant w<strong>at</strong>er per day. Arrangement for setting of silt / sludge etc from the drain w<strong>at</strong>er<br />

should be ensured before entering oil w<strong>at</strong>er separ<strong>at</strong>or unit having capacity to<br />

accumul<strong>at</strong>e silt/sludge approxim<strong>at</strong>e 20 Cu.Mtrs.<br />

3. Expected Parameters of effluent <strong>at</strong> output<br />

Suitable arrangement for Physical / Chemical / Biological tre<strong>at</strong>ment of effluent<br />

flowing out of oil w<strong>at</strong>er separ<strong>at</strong>or, so as to achieve effluent level in final discharge as<br />

mentioned in Para 4.<br />

4. Parameters of effluent output<br />

Suitable arrangement to be provided for Physical / Chemical tre<strong>at</strong>ment of<br />

effluent to achieve effluent level in final discharge as indic<strong>at</strong>ed below:<br />

Sl. No.<br />

Parameters<br />

(AS PER TESTING<br />

REPORT OF HBTI<br />

CNB DATED<br />

23/02/2004) Present<br />

level after OWS<br />

Desired level<br />

after tre<strong>at</strong>ment in<br />

ETP<br />

Unit<br />

1 PH 8.4 5.5 – 9.0 Mg/Ltr<br />

2 TDS 628 ≤ 2100 Mg/Ltr<br />

3 TSS 70 ≤ 100 Mg/Ltr<br />

4 BOD 46 ≤ 30 Mg/Ltr