Design, Supply, Transportation, Erection at site, Commissioning

Design, Supply, Transportation, Erection at site, Commissioning

Design, Supply, Transportation, Erection at site, Commissioning

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

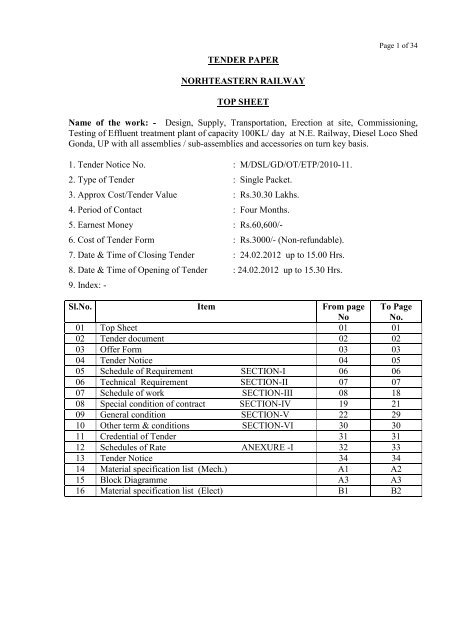

TENDER PAPER<br />

Page 1 of 34<br />

NORHTEASTERN RAILWAY<br />

TOP SHEET<br />

Name of the work: - <strong>Design</strong>, <strong>Supply</strong>, <strong>Transport<strong>at</strong>ion</strong>, <strong>Erection</strong> <strong>at</strong> <strong>site</strong>, <strong>Commissioning</strong>,<br />

Testing of Effluent tre<strong>at</strong>ment plant of capacity 100KL/ day <strong>at</strong> N.E. Railway, Diesel Loco Shed<br />

Gonda, UP with all assemblies / sub-assemblies and accessories on turn key basis.<br />

1. Tender Notice No. : M/DSL/GD/OT/ETP/2010-11.<br />

2. Type of Tender : Single Packet.<br />

3. Approx Cost/Tender Value : Rs.30.30 Lakhs.<br />

4. Period of Contact : Four Months.<br />

5. Earnest Money : Rs.60,600/-<br />

6. Cost of Tender Form : Rs.3000/- (Non-refundable).<br />

7. D<strong>at</strong>e & Time of Closing Tender : 24.02.2012 up to 15.00 Hrs.<br />

8. D<strong>at</strong>e & Time of Opening of Tender : 24.02.2012 up to 15.30 Hrs.<br />

9. Index: -<br />

Sl.No. Item From page<br />

No<br />

To Page<br />

No.<br />

01 Top Sheet 01 01<br />

02 Tender document 02 02<br />

03 Offer Form 03 03<br />

04 Tender Notice 04 05<br />

05 Schedule of Requirement SECTION-I 06 06<br />

06 Technical Requirement SECTION-II 07 07<br />

07 Schedule of work SECTION-III 08 18<br />

08 Special condition of contract SECTION-IV 19 21<br />

09 General condition SECTION-V 22 29<br />

10 Other term & conditions SECTION-VI 30 30<br />

11 Credential of Tender 31 31<br />

12 Schedules of R<strong>at</strong>e ANEXURE -I 32 33<br />

13 Tender Notice 34 34<br />

14 M<strong>at</strong>erial specific<strong>at</strong>ion list (Mech.) A1 A2<br />

15 Block Diagramme A3 A3<br />

16 M<strong>at</strong>erial specific<strong>at</strong>ion list (Elect) B1 B2

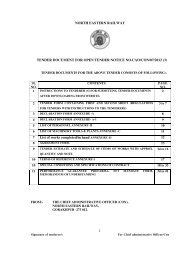

TENDER DOCUMENT<br />

Page 2 of 34<br />

N.E. RAILWAY<br />

OFFICE OF THE<br />

SR. DIVISIONAL MECHANICAL ENGINEER (DIESEL)<br />

N.E. RAILWAY<br />

DIESEL LOCO SHED/GONDA – 271002.<br />

U.P.<br />

------------------------------------------------------------------------------------------------------------------<br />

TENDER NO. : M/DSL/GD/OT/ETP/2010-11<br />

FOR DESIGN, SUPPLY, TRANSPORTATION, ERECTION AT SITE, COMMISSIONING<br />

AND TESTING OF EFFLUENT TREATMENT PLANT AT N.E. RAILWAY DIESEL<br />

LOCO SHED, GONDA, U.P. WITH ALL ASSEMBLIES/ SUBASSEMBLIES AND<br />

ACCESSORIES ON TURN KEY BASIS.<br />

TENDER DOCUMENT<br />

ISSUED BY :<br />

SR. DIVL. MECH. ENGINEER (DIESEL)<br />

N.E. RAILWAY, DIESEL LOCO SHED,<br />

GONDA (U.P.) – 271002.<br />

Phone No. 05262 – 260080<br />

E. mail – srdmegd@gmail.com<br />

ISSUED TO :<br />

M/s ………………………………….<br />

………………………………………<br />

………………………………………<br />

………………………………………<br />

………………………………………<br />

Price : Rs. 3,000/- (Rupees Three Thousand only)<br />

Cash Receipt No. -------------------------------------------------------<br />

NOTE : All tender documents shall be returned to this office in original, duly signed and<br />

stamped on each page by the tenderer.<br />

Total number of pages:<br />

34+5 pages enclosure.

OFFER FORM<br />

Page 3 of 34<br />

TENDER NO. : M/DSL/GD/OT/ETP/2010-11<br />

Name of work : <strong>Design</strong>, <strong>Supply</strong>, <strong>Transport<strong>at</strong>ion</strong>, <strong>Erection</strong> <strong>at</strong> Site, <strong>Commissioning</strong> and Testing<br />

of Effluent Tre<strong>at</strong>ment Plant <strong>at</strong> N.E. Railway, Diesel Shed Gonda (U.P.) with<br />

all assemblies / sub-assemblies and accessories on turn key basis.<br />

------------------------------------------------------------------------------------------------------------<br />

To,<br />

The President of India,<br />

Acting through Sr. Divl. Mech. Engineer (DSL),<br />

N.E. Railway, Diesel Loco Shed/Gonda(U.P.) – 271002.<br />

Telephone No. : 05262 – 260080.<br />

1. I/We ………………………………………………………………………… have read<br />

the various conditions to the tender <strong>at</strong>tached hereto and hereby agree to abide by the<br />

such conditions. I/We also agree to keep this tender open for acceptance for a period of<br />

120 days from the d<strong>at</strong>e fixed for opening of the same and default thereof. I/We will be<br />

liable forfeiture of my/our “Earnest Money”. I/We offer to do the work for<br />

Sr. Divisional Mechanical Engineer (Diesel), N.E. Railway, Diesel Shed, Gonda <strong>at</strong> the<br />

r<strong>at</strong>e quoted in the <strong>at</strong>tached schedule and hereby bind myself/ourselves to complete the<br />

work in all respects within stipul<strong>at</strong>ed period of time from the d<strong>at</strong>e of issue of letter of<br />

acceptance of the tender. I/We also hereby agree to abide by the general and special<br />

conditions of the contract of Railway – 1999 upd<strong>at</strong>ed till d<strong>at</strong>e and to carry out the work<br />

according to the specific<strong>at</strong>ion for m<strong>at</strong>erial and work laid down by the Railway for the<br />

present contract as well as all other enclosures annexed to the tender form.<br />

2. A sum of Rs. 60,600/- (Rupees Sixty thousand and six hundred only) depo<strong>site</strong>d vide<br />

Receipt No. ……………..… D<strong>at</strong>ed …………… in favour of FA&CAO, N.E. Rly,<br />

Gorakhpur is herewith forwarded as “Earnest Money”. The original receipt is enclosed<br />

with the offer. The full value of earnest money shall stand forfeited without prejudice to<br />

any other rights or remedies available to Railway if.<br />

a) I/We do not execute the contract documents within 15 days after receipt of Notice<br />

issued by the Railways th<strong>at</strong> such documents are ready. ‘OR’<br />

b) I/We do not commence the work within 10 days after receipt of order to th<strong>at</strong> effect.<br />

3. Until a formal agreement is prepared and executed, acceptance of this tender shall<br />

constitute a binding contract between us subject to modific<strong>at</strong>ions as may be mutually<br />

agreed to between us and indic<strong>at</strong>ed in the letter of acceptance of my/our offer for this<br />

work.<br />

Sign<strong>at</strong>ure of Witnesses<br />

(Along with complete address)<br />

(SIGNATURE OF TENDERER)<br />

Tenderer’s Address<br />

No. 1 : ----------------------------- ---------------------------------<br />

-------------------------------------- ---------------------------------<br />

No. 2 : ----------------------------- ---------------------------------<br />

-------------------------------------- ---------------------------------

North Eastern Railway<br />

Page 4 of 34<br />

Office of the Sr. Divisional Mechanical Engineer (Diesel)<br />

North Eastern Railway, Gonda – 271002<br />

Tender Notice (for Web<strong>site</strong>)<br />

Open Tender Notice No. M/DSL/GD/OT/ETP/2010-11, d<strong>at</strong>ed: 27.12.2011<br />

Sealed open tenders are invited in the prescribed form for and on behalf of the President of<br />

India (Acting through Sr. Divisional Mechanical Engineer (Diesel), N.E. Railway, Gonda),<br />

which will be received up to 15.00 Hrs. on 24.02.2012 and opened on the same d<strong>at</strong>e <strong>at</strong> 15.30<br />

hrs, from reputed tenders having required experience, capability and financial st<strong>at</strong>us for the<br />

following work:<br />

Name of Work<br />

100 KL/Day - <strong>Design</strong>,<br />

<strong>Supply</strong>, <strong>Transport<strong>at</strong>ion</strong>,<br />

<strong>Erection</strong> <strong>at</strong> Site and<br />

<strong>Commissioning</strong> & Testing<br />

of Effluent Tre<strong>at</strong>ment<br />

Plant <strong>at</strong> N.E. Railway,<br />

Diesel Shed Gonda (U.P.)<br />

with all assemblies/subassemblies<br />

and accessories<br />

on turn key basis.<br />

The tender<br />

assessed<br />

cost<br />

Cost of<br />

prescribed<br />

form<br />

Earnest<br />

Money<br />

D<strong>at</strong>e and<br />

time of<br />

opening<br />

Rs.3030000/- Rs.3000/- Rs.60600/- 24.02.2012<br />

<strong>at</strong> 15.30hrs<br />

Completion<br />

period of<br />

the work<br />

04 Months<br />

2.0 Scope of the work: ETP (100 KL/DAY)<br />

(i) Scope of work for 3 Chambered Effluent Collection Sump with pumping st<strong>at</strong>ion is as<br />

under :- Grit Chamber, Screen chamber & screen, Oil Grease separ<strong>at</strong>or and trap, Wet well<br />

and ventil<strong>at</strong>ion, Effluent Transfer Pump, Manifold & Hoist, Pumping main from pumping<br />

st<strong>at</strong>ion to Mechanical ETP.<br />

(ii) Scope of Work for Effluent Tre<strong>at</strong>ment Plant (100 KL/day):-<br />

Self driven effluent conditioners, Autom<strong>at</strong>ic Oil-W<strong>at</strong>er Separ<strong>at</strong>or, Oil skimmer,<br />

Floccul<strong>at</strong>ion Chamber with Mechanical Structures, Diffused Air Flo<strong>at</strong><strong>at</strong>ion Unit (DAF),<br />

Dual Chambered Moving bed bio reactor with all its ancillaries like- FBM Aer<strong>at</strong>ors and<br />

Bio Media, Secondary setting zone inclined tube settler, PEL Dosing Unit, Ozone<br />

Gener<strong>at</strong>or with all its ancillaries, Multi-Grade Filtr<strong>at</strong>ion Unit, Activ<strong>at</strong>ed Carbon Filtr<strong>at</strong>ion<br />

Unit, Sludge drying beds and required piping & valves, Sludge Pump with required piping,<br />

Tre<strong>at</strong>ed w<strong>at</strong>er storage tank, Inline feed pumps with required piping and valves, Blower with<br />

required piping and valves.<br />

3.0 Minimum eligibility criteria have been stipul<strong>at</strong>ed for consider<strong>at</strong>ion of the offers received in<br />

response to this tender notice and the same is available on the North eastern Railway’s<br />

web<strong>site</strong>. Tenderers are required to visit the web<strong>site</strong>, go through the eligibility criteria laid<br />

down and must submit with their offer all documents in support of the same along with<br />

their financial st<strong>at</strong>us, past experience, ability to execute the work etc as per details<br />

contained in the prescribed form. The Minimum eligibility criteria are:<br />

a. Tenderer(s) should have completed <strong>at</strong> least one similar single work for a minimum value of<br />

35% of advertised tender value in last three financial years (i.e. current year + 3 previous<br />

financial years).

Page 5 of 34<br />

b. Tenderer(s) should have received total contractual amount against s<strong>at</strong>isfactory execution/<br />

work in progress of all type works for a minimum of 150% of advertised tender value of<br />

work during last three financial years (i.e. current year and three previous financial years).<br />

(i) Similar work would mean th<strong>at</strong> the tenderer should have executed a work of Effluent<br />

Tre<strong>at</strong>ment Plant.<br />

(ii) The current year shall mean the period upto the d<strong>at</strong>e of opening as originally advertised in<br />

the Newspapers. The extended d<strong>at</strong>e of opening, if any, shall not be taken into account for<br />

this purpose.<br />

4.0 The prescribed form is not transferable and may be purchased from the office of the Sr.<br />

Divisional Mechanical Engineer (Diesel), North Eastern Railway, Gonda-271002 on and<br />

from 23.01.2012 between 10.00 hrs to 15.00 Hrs. up to one working day prior to the d<strong>at</strong>e of<br />

opening of the tender after payment of cost of the same with the Chief Cashier, North<br />

eastern Railway, Lucknow and on production of the receipt thereof. The tenderre, who<br />

wishes to obtain the prescribed form by post, should send cost thereof plus a sum of Rs.<br />

500/- (Rupees five hundred) as postal charges and Rs. 200/- (Rupees two hundred) for<br />

relevant plans and drawings Money Order to Sr. Divisional Mechanical Engineer(Diesel),<br />

North Eastern Railway, Gonda-271002. Under no circumstances, amount paid for the<br />

prescribed form shall be refunded.<br />

5.0 Tenders must be accompanied with the aforesaid earnest money in acceptable forms as<br />

detailed in the prescribed form. No adjustment of the earnest money submitted with earlier<br />

tenders, including tenders, which have already been accepted, shall be done. The tenders<br />

received without the aforesaid earnest money shall be summarily rejected.<br />

6.0 Tenderers may download the prescribed form from the North eastern Railway’s web<strong>site</strong><br />

“http://www.nerailway.gov.in” and “www.tenders.gov.in” also. However, aforesaid cost of<br />

such prescribed form shall have to be paid in the shape of demand draft in favour of<br />

FA&CAO, North Eastern Railway, Gorakhpur as an enclosure to the tender offer. Offers<br />

received in the prescribed form downloaded from the web<strong>site</strong> without valid demand draft<br />

for the full cost thereof shall be summarily rejected. In case it is detected <strong>at</strong> any time th<strong>at</strong> a<br />

tenderer/ contractor has added/deleted/modified the contents of the prescribed form during<br />

and/ or after downloading, the tender shall be discharged, the contract shall be termin<strong>at</strong>ed<br />

and tenderer/ contractor would be liable for removal of its name from the approved list,<br />

banning/ suspension of business dealings etc. in addition to other legal remedies available<br />

with the Railway. The tenderers must, therefore, note these aspects carefully.<br />

7.0 Tenders must be submitted in the prescribed form purchased from the above office only,<br />

must be in a sealed cover and must be dropped in the nomin<strong>at</strong>ed ‘tender box’ kept in<br />

Conference hall in the office of the Sr. Divisional Mechanical Engineer (Diesel), North<br />

Eastern Railway, Gonda-271002 up to scheduled d<strong>at</strong>e of opening of the tender till 15.00<br />

hrs, when the said tender box would be closed. The tender box will be opened on the tender<br />

opening day <strong>at</strong> 15.30 hrs. in presence of tenderers or their authorised represent<strong>at</strong>ives who<br />

wish to remain present.<br />

8.0 In case the tender receiving day/ the tender opening day is declared a holiday due to any<br />

reason, the tender box shall be closed <strong>at</strong> the same time on the next working day and shall be<br />

opened <strong>at</strong> the same time on th<strong>at</strong> day.<br />

9.0 As the advertised tender value of the work is less than Rs. 5.00 crore, no purchase<br />

preference would be admissible to the Central Public Sector Enterprises.<br />

10.0 No price Vari<strong>at</strong>ion Clause would be applicable in the present tender case.<br />

11.0 Joint Venture shall not be considered.<br />

Sr. Divisional Mechanical Engineer(Diesel),<br />

For & on behalf of the President of India

Page 6 of 34<br />

SCHEDULE OF REQUIREMENT :<br />

Section -I<br />

S.No. Particulars<br />

1. Name of Work : <strong>Design</strong>, <strong>Supply</strong>, <strong>Transport<strong>at</strong>ion</strong>, <strong>Erection</strong> <strong>at</strong> Site, <strong>Commissioning</strong><br />

and Testing of Effluent Tre<strong>at</strong>ment Plant <strong>at</strong> N.E. Railway, Diesel<br />

Shed Gonda (U.P.) with all assemblies / sub-assemblies and<br />

accessories on turn key basis.<br />

2. Type of Tender : Open Tender<br />

3. Work to be done : As per the Tender Schedule.<br />

4. Approx value of work : Rs. 30.30 Lakhs.<br />

5. Place of work : N.E. Railway, Diesel Loco Shed/Gonda.<br />

6. Completion Period : Within 120 days from the signing of contract.<br />

7. Cost of Tender Form : Rs. 3,000/-<br />

8. Earnest Money : Rs. 60,600/-<br />

9. Last d<strong>at</strong>e and time of : 24.02.2012 up to 15.00 Hrs.<br />

submission of Tender<br />

10. Tender opening d<strong>at</strong>e : 24.02.2012 <strong>at</strong> 15.30 Hrs.<br />

and time

TECHNICAL REQUIREMENT<br />

Page 7 of 34<br />

Section-II<br />

Tender is required to carry out the work of effluent tre<strong>at</strong>ment plant as a turn key project<br />

and all the civil / mechanical / piping and machinery and plants is required to be provided by<br />

the tenderer only. Tenderer will also arrange and provide the following:<br />

1. Lay out plan indic<strong>at</strong>ing various structures pipe lines, drainage, w<strong>at</strong>er storage tanks for<br />

oil tre<strong>at</strong>ed w<strong>at</strong>er etc. on the basis of actual <strong>site</strong>s condition of Diesel shed Gonda.<br />

2. Details of schem<strong>at</strong>ic diagrams / specific<strong>at</strong>ion and Civil structures including oil tanks.<br />

3. Details of effluent tre<strong>at</strong>ment plant covering design specific<strong>at</strong>ion / detailed schem<strong>at</strong>ic<br />

diagrams and process should be certified by a quality agency. The layout and processes<br />

should be in consonance with norms stipul<strong>at</strong>ed in ISO 9001;14001 & also OSAS<br />

18001.<br />

4. Details of all machinery and plant including electrical equipments covering design,<br />

specific<strong>at</strong>ion make and capacity etc.<br />

5. Details of inputs required by the Diesel shed Gonda for running the effluent plants in<br />

terms of man power, electricity, w<strong>at</strong>er, gas, HSD etc. and recharging consumable if<br />

any.<br />

6. Details of all other works rel<strong>at</strong>ed to effluent tre<strong>at</strong>ment plants.<br />

7. Details of integr<strong>at</strong>ed control circuits and instrument<strong>at</strong>ion etc.<br />

8. Compar<strong>at</strong>ive technical advantage of the technological offer in the tech bid compared to<br />

other technologies available in the market from technical, reliability and energy<br />

consumption point of view.<br />

9. Conserv<strong>at</strong>ion of energy man power and consumables.<br />

10. The tre<strong>at</strong>ed w<strong>at</strong>er should be first stored in a surface tank of 25 KL capacity and then to<br />

be pumped out to overhead tank of 100 KL capacity. The supply of tre<strong>at</strong>ed w<strong>at</strong>er from<br />

the overhead tank to be given to washing line etc (delete and which should be by<br />

gravity). by pump. The overhead tank should also be connected with city drain.<br />

Connection should also be made to discharge tre<strong>at</strong>ed w<strong>at</strong>er directly from surface<br />

storage tanks to city drain by gravity.(pump)<br />

11. Details of skimming arrangement preferably belt type (Oleophillic)

A. Scope of Work<br />

SCHEDULE OF WORK<br />

Page 8 of 34<br />

SECTION- III<br />

The Broad scope of work includes setting up effluent tre<strong>at</strong>ment system for handling<br />

effluent w<strong>at</strong>er of N.E. Railway Diesel Locomotive Shed Gonda on turn key basis.<br />

It is expected the tenderer will thoroughly study and under take to design, supply<br />

erection commission the effluent tre<strong>at</strong>ment system for effluent discharge from shed is properly<br />

tre<strong>at</strong>ed to the l<strong>at</strong>est (as on the d<strong>at</strong>e of notific<strong>at</strong>ion of tender) stipul<strong>at</strong>ed norms as laid down as<br />

per UPPCB/UP or as per Govt. of India norms by the Pollution Control Board (CPCB). The<br />

tre<strong>at</strong>ed w<strong>at</strong>er is likely to be connected with (washing pit) city drain. The parameters of the<br />

tre<strong>at</strong>ed w<strong>at</strong>er desired or specified under the detailed scope of work. Drainage should be made<br />

by Railway.<br />

It is presumed th<strong>at</strong> the approxim<strong>at</strong>e capacity of the plant would be in the range of<br />

100 KL per day.<br />

(1) (i) Scope of work for 3 Chambered Effluent Collection Sump with pumping st<strong>at</strong>ion is<br />

as under :-<br />

Grit Chamber, Screen chamber & screen, Oil Grease separ<strong>at</strong>or and trap, Wet well and<br />

ventil<strong>at</strong>ion, Effluent Transfer Pump, Manifold & Hoist, Pumping main from pumping<br />

st<strong>at</strong>ion to Mechanical ETP as per Block Diagram enclosed (enclosed <strong>at</strong> annexure ‘A3’).<br />

The firm will have to supply the m<strong>at</strong>erial as per list enclosed <strong>at</strong> annexure ‘A1’ & ‘A2’.<br />

(ii) Scope of Work for Effluent Tre<strong>at</strong>ment Plant:-<br />

Self driven effluent conditioners,<br />

Autom<strong>at</strong>ic Oil-W<strong>at</strong>er Separ<strong>at</strong>or<br />

Oil skimmer<br />

Floccul<strong>at</strong>ion Chamber with Mechanical Structures<br />

Diffused Air Flo<strong>at</strong><strong>at</strong>ion Unit (DAF)<br />

Dual Chambered Moving bed bio reactor with all its ancillaries like- FBM Aer<strong>at</strong>ors<br />

and Bio Media<br />

Secondary setting zone inclined tube settler<br />

PEL Dosing Unit<br />

Ozone Gener<strong>at</strong>or with all its ancillaries<br />

Multi-Grade Filtr<strong>at</strong>ion Unit<br />

Activ<strong>at</strong>ed Carbon Filtr<strong>at</strong>ion Unit<br />

Sludge drying beds and required piping & valves<br />

Sludge Pump with required piping<br />

Tre<strong>at</strong>ed w<strong>at</strong>er storage tank<br />

Inline feed pumps with required piping and valves<br />

Blower with required piping and valves<br />

Common scope of work to ETP & Pumping St<strong>at</strong>ion are as under:-<br />

Panel Board, Instrument<strong>at</strong>ion & control system, External and Internal Power supply,<br />

Control Room, Inspection & Testing; Performance Guarantee.<br />

2. Detailed of Scope of work:<br />

(i) Chambered Effluent Collection Sump with Pumping St<strong>at</strong>ion should be designed to<br />

provide:<br />

Separ<strong>at</strong>ion of Oil & Grease contents from the effluent through 2 nos. Riser Pipes to be<br />

provided in to the chambers.<br />

Separ<strong>at</strong>ion of Grits and larger solids from the effluent.<br />

Separ<strong>at</strong>ion of other flo<strong>at</strong>ing m<strong>at</strong>erials from the effluent through Screen.

Acceptable pump intake conditions.<br />

Adequ<strong>at</strong>e volume to prevent excessive pump cycling, and<br />

Sufficient depth for pump control, while minimizing solids deposition.<br />

Page 9 of 34<br />

(ii) At normal oper<strong>at</strong>ing levels, the following should be considered in the design;<br />

Reduce or elimin<strong>at</strong>e the free fall of effluent in to the wet well<br />

Minimise rot<strong>at</strong>ion of w<strong>at</strong>er <strong>at</strong> the pump intake<br />

Provide adequ<strong>at</strong>e submergence to minimize surface vortices<br />

Loc<strong>at</strong>e the pumps to minimize the form<strong>at</strong>ion of subsurface vortices<br />

(iii) The capacity of the wet well shall be not less than 30.00 KL<br />

(iv) Oil and Grease contents of the effluent, trapped in the first chamber shall be removed<br />

through Belt type Oil Skimmer. This will be installed in to the first chamber.<br />

(v) The wet well structure shall be designed to withstand the hydrost<strong>at</strong>ic forces including<br />

buoyancy forces. Stair in corrosion resistant m<strong>at</strong>erial shall be provided for access in<br />

to the wet well.<br />

(vi) Cover slab for wet well shall be RCC.<br />

(vii) Control Room Electrical Work:<br />

The lists of approved sources are being <strong>at</strong>tached in Annexure B1 & B2.<br />

(ix) Panel Board, instrument<strong>at</strong>ion & control system<br />

A motor protective system th<strong>at</strong> combines control and protection functions in<br />

one assembly for all the motors shall be provided. The package shall include motor<br />

over load protection, over temper<strong>at</strong>ure, instantaneous over current, ground fault,<br />

phase loss/ phase reversal/ phase unbalance (voltage), phase loss and unbalance<br />

(current), over voltage, under voltage, motor bearing temper<strong>at</strong>ure etc.<br />

(A) NOTE:<br />

1. The monitoring fe<strong>at</strong>ures shall include ampere and voltage.<br />

2. Consider<strong>at</strong>ion must be given to the oper<strong>at</strong>ing environment such as temper<strong>at</strong>ure and<br />

extremely humid environment.<br />

3. The system should be provided with single phase preventer, over-load protector.<br />

4. Adequ<strong>at</strong>e electrical fittings on the plant and in the control room will have to be<br />

provided by the tenderer.<br />

5. Complete lay-out drawings / circuit diagrams should be submitted along with offer.<br />

6. A d<strong>at</strong>a processing machine to following specific<strong>at</strong>ion should be provided for d<strong>at</strong>a<br />

recording and rel<strong>at</strong>ed work of ETP.<br />

(B) Specific<strong>at</strong>ion for d<strong>at</strong>a processing machine:<br />

1. 1GB DDR2, RAM<br />

2. Network card 10/100 MBPS.<br />

3. 2 Parallel, 2Serial and 2USB ports.<br />

4. 18.5” LCD Colour Monitor<br />

5. 1KVA ,UPS,double b<strong>at</strong>tery.<br />

6. Pentium Intel core 2DUO Processor ,2.93 Ghz.<br />

7. Intel G-41 Mother Board.

Page 10 of 34<br />

8. DVD Writer.<br />

9. 320 GB D<strong>at</strong>a-Hard –Disc.<br />

10. Ink-jet Printer.<br />

11. Multi-media Key-Board.<br />

12. Three- button optical mouse.<br />

13. Multi-media speaker.<br />

14. Oper<strong>at</strong>ing system- Windows XP processor with licenses.<br />

15. MS Office-2010 Antivirus with license.<br />

Incase of non-availability of specific brand of the above the firm shall take permission<br />

from the competent authority for the brand being purchased.<br />

DETAIL DESIGN DATA FOR E.T.P.<br />

1. Capacity :<br />

The capacity of Effluent Tre<strong>at</strong>ment Plant is 12.50 KLH (Average flow). The peak<br />

factor for the design purpose is to be taken as 1.5.<br />

2. Effluent characteristics (given by tendrer in previous offers)<br />

N<strong>at</strong>ure of Waste<br />

: Industrial effluent<br />

C.O.D. (Max.) : 1200<br />

B.O.D. (Max.)<br />

: 800 mg/l<br />

S.S.<br />

: 4000 mg/l<br />

T.D.S.<br />

: 6800 mg/l<br />

Oil & Grease<br />

: 5000 mg/l<br />

Av. <strong>Design</strong> flow r<strong>at</strong>e : 12.50 KLH<br />

Peak flow factor : 1.5<br />

Feed<br />

: Pumped to inlet-port of Oil-W<strong>at</strong>er Separ<strong>at</strong>or.<br />

3. Tre<strong>at</strong>ed W<strong>at</strong>er Standard :<br />

FINAL EFFULENT QUALITY SHOULD BE CONFORMING TO THE LATEST(AS<br />

ON DATE OF NOTIFICATION OF TENDER) NORMS OF UPPCB/CPCB.<br />

B.O.D. (Max.)<br />

: 30 mg/l<br />

C.O.D. (Max.)<br />

: 250 mg/l<br />

S.S.<br />

: 100 mg/l<br />

T.D.S.<br />

: 2100 mg/l<br />

Oil & Grease<br />

: 10 mg/l<br />

MECHANICAL & ELECTRICAL WORKS<br />

1. Fully Autom<strong>at</strong>ic Oil-W<strong>at</strong>er Separ<strong>at</strong>or<br />

No. of Unit : 1<br />

Type<br />

: Fully autom<strong>at</strong>ic in Cylindrical shape<br />

MOC of Shell<br />

: MS as per IS 2062, Sand blasted and epoxy painted<br />

Oil-W<strong>at</strong>er Interface Sensor : To be Provided.<br />

Electro-Pneum<strong>at</strong>ic Valve : to be Provided.<br />

Capacity<br />

: 12.50 KLH<br />

2. DAF Unit<br />

No. of Required<br />

: 01 Set<br />

Type<br />

: Rectangular with hopper bottom.<br />

MOC<br />

: Mild steel epoxy painted.<br />

Skid<br />

: Provided.<br />

S<strong>at</strong>ur<strong>at</strong>ion Tank<br />

: Provide.<br />

Pressure Gauge<br />

: Provided.<br />

Pressure relief valve : provided.

Page 11 of 34<br />

DAF recircul<strong>at</strong>ion pump : Provided.<br />

Pressure Control Valve : Provided.<br />

Skimmer Assembly : Provided.<br />

Setting Zone<br />

: Provided.<br />

ECO 2<br />

: Provided 2 Nos.<br />

3. Parallel Effluent Conditioner<br />

No. of Units : 2<br />

MOC<br />

: M.S. Sand blasted and epoxy painted.<br />

Drive<br />

: Self<br />

Arrangement of chemical : To be provided.<br />

injection.<br />

Drain out<br />

: To be provided.<br />

4. Floccul<strong>at</strong>ion Zone<br />

No. of Unit : 1<br />

MOC<br />

: M.S. Epoxy painted<br />

Floccul<strong>at</strong>ion Through : Air Mixing / SS Floccul<strong>at</strong>or<br />

5. Moving Bed Bio Reactor<br />

No. of Unit : 1<br />

No. of Chambers : 2<br />

MOC<br />

: MS Epoxy painted.<br />

Applied Organic Load : 60 kg/BOD 5<br />

Type of Aer<strong>at</strong>ors<br />

: Fine Bubble Membrane<br />

MOC of Membrane : High Grade EPDM<br />

Nos. and size of Aer<strong>at</strong>ors : As per design to be submitted by firm<br />

Type of Bio Media : Random UV Sterilized PP<br />

Retention Period<br />

: As per design<br />

6. Multi-Grade Filter<br />

No. of Unit : 1<br />

MOC of Shell : MS as per IS 2062<br />

Type<br />

: Pressurized Down flow<br />

Media Depth<br />

: 900 mm<br />

Media Type<br />

: Oleophilic Graded Granular Sand and Anthracites.<br />

Under drainage<br />

: To be provided.<br />

Back wash facility<br />

: To be provided.<br />

ROF<br />

: 15000 L/H/M2<br />

7. Activ<strong>at</strong>ed Carbon filter<br />

No. of Unit : 1<br />

MOC of Shell : MS as per IS 2062<br />

Column Ht.<br />

: 2000 mm<br />

Type of media<br />

: Granular Activ<strong>at</strong>ed Carbon Gr-1000<br />

8. Effluent Transfer pumps<br />

No. of Units<br />

: 2 (1 W + 1 SB)<br />

Type<br />

: Non Clog Submersible<br />

Capacity<br />

: 20000 LPH <strong>at</strong> 14 M Head<br />

Drive<br />

: In Built with adequ<strong>at</strong>e HP<br />

Make<br />

: Kirloskar/Kishore/KSB/Equivalent<br />

9. Inline Feed pumps<br />

No. of Units<br />

: 2 (1 W + 1 SB)<br />

Type<br />

: Inline Centrifugal<br />

Capacity<br />

: 20000 LPH <strong>at</strong> 18 M Head<br />

Drive<br />

: Squirrel Cage-Horizontal Foot mounted

Enclosure<br />

: T.E.F.C., We<strong>at</strong>her proof, IP-55<br />

Make<br />

: Kirloskar/Kishore/KSB/Equivalent<br />

10. Sludge pumps<br />

No. of Units<br />

: 2 (1 W + 1 SB)<br />

Type<br />

: Horizontal, Non Clog<br />

Solid Handling capacity : 6 mm<br />

Capacity of Pump<br />

: 5000 LPH <strong>at</strong> 10 M Head<br />

Drive<br />

: Squirrel Cage-Horizontal Foot mounted<br />

Enclosure<br />

: T.E.F.C., We<strong>at</strong>her proof, IP-55<br />

Make<br />

: Kirloskar/Kishore/KSB/Equivalent<br />

11. Blowers<br />

No. of Units : 1<br />

Capacity<br />

: As per design<br />

Type<br />

: Twin Lobe<br />

Drive<br />

: Squirrel Cage-Horizontal Foot mounted<br />

Enclosure<br />

: T.E.F.C., We<strong>at</strong>her proof, IP-55<br />

Make<br />

: Kay/Everest/VE/SI/Kulkarni<br />

12. Chemical Dosing Pumps<br />

No. of Units : 2<br />

No. of Chemical Storage Tank : 2, each of 100 ltrs capacity.<br />

Type of Pumps<br />

: Metering<br />

Make<br />

: Milton Roy / Equivalent<br />

13. Ozone Gener<strong>at</strong>or<br />

No. of Units : 1<br />

Capacity<br />

: As per requirement<br />

Type<br />

: Crona Discharge<br />

O2 Gener<strong>at</strong>or Pump : To be provided.<br />

14. Screen<br />

No. of Units : 2<br />

MOC<br />

: MS<br />

Size<br />

: As per design<br />

15. Oil Skimmer<br />

Bo of Unit : 1<br />

Type<br />

: Double Drum Belt type<br />

Capacity<br />

: 120 LPH<br />

Page 12 of 34<br />

16. Interconnecting pipeline and valves<br />

Piping<br />

: As per detail Engineering Options M.S.BI. Medium class as per<br />

IS – 1239 PVC Class III as per IS : 4985 H.D.P.E. Class III as<br />

per IS : 498 Class LA as per IS : 1537 & 7181<br />

Valves<br />

: ISI marked C.I.D/F PN – 1 class confirming to IS : 780 with<br />

hand wheel for 80 dia & above and ISI marked PP Valves up to<br />

50 dia.<br />

Extended Oper<strong>at</strong>ion : C.I. Headstock Assembly with coupling for extended oper<strong>at</strong>ion<br />

of valves wherever of valve through 20/25 G.I. Medium pipe conforming to IS:<br />

necessary<br />

1239& equivalent<br />

17. Control panel<br />

Type<br />

: Desk type with Mimic Diagram<br />

Main Switch<br />

: To be provided (REQUIRED)<br />

Starters<br />

: To be provided<br />

3 Ph Indic<strong>at</strong>or : To be provided

SPP<br />

Digital Amp Meter<br />

Digital Volt Meter<br />

Level Sensors<br />

Digital Flow meter<br />

Digital PH Meter<br />

Auto/Manual Switch for<br />

Electro-Pneum<strong>at</strong>ic valve<br />

CIVIL WORKS<br />

: To be provided<br />

: To be provided<br />

: To be provided<br />

: To be provided for Submersible Effluent pumps.<br />

: To be provided<br />

: To be provided<br />

: To be provided<br />

Page 13 of 34<br />

1. 3Chambered Effluent Collection Sump (Capacity: 30 KL)<br />

Grit Chamber<br />

: To be provided in Effluent Collection Sump as per design<br />

Screen Chambers (2Nos) : To be provided in the incoming drain as per design<br />

Oil & Grease Separ<strong>at</strong>or : To be provided in Effluent Collection Sump as per design<br />

Oil & Grease Trap : To be provided in Effluent Collection Sump as per design<br />

Wet Well<br />

: To be provided in Effluent Collection Sump as per design<br />

MOC of above Structures : RCC M-25<br />

2. Control Room<br />

Size : 12.00 M2, 3.00 Ht. (PROVISION OF 2 SPLIT 2 TONNE<br />

AIR CONDITIONERS)<br />

Walls : Brick Work in CM 1:4<br />

Roof : RCC M-20<br />

Door<br />

: 1 no of size 2100mmx1200mm in MS<br />

Windows<br />

: 1 no of size 1500mmx1200mm in Aluminium frame with<br />

glass<br />

Floor<br />

: Ceramic Tiles<br />

3. Tre<strong>at</strong>ed W<strong>at</strong>er Storage Reservoir (Capacity:30.00 KL)<br />

MOC : RCC M-25<br />

Free Board<br />

: 300 mm<br />

Over flow arrangement : To be provided.<br />

Detail design : To be provided by firm<br />

4. Pl<strong>at</strong>form for the Entire Mechanical Plant with CGI Roofing<br />

Size<br />

: As per requirement and design<br />

MOC : B/W, PCC M-15 & RCC M-20<br />

5. Sludge Drying Beds<br />

No. of Units : 4<br />

Size of beds : as per design<br />

Construction of beds : In Bricks Masonry with 1:4:8 P.C.C. bed<br />

Filter return line : 90 mm dia. Pipe line from sludge drying beds to Wet Well<br />

Valves for Isol<strong>at</strong>ion : 4 Nos. 40 mm dia G<strong>at</strong>e Valve.<br />

of each bed<br />

B. Scope of Work<br />

The tenderer will be expected to cover the following works as given below:<br />

1. Identifying the type and the sources of effluent. The Diesel locomotive shed Gonda has<br />

the following Major sources of effluent. The tenderer must study the <strong>site</strong> of the shed for<br />

correct estim<strong>at</strong>ion of the type and the sources of effluent. As guidance the following<br />

known sources of pollutants are depicted below:

1.1 Loco maintenance Bays<br />

Page 14 of 34<br />

Pollutants consist of w<strong>at</strong>er, HSD, lubric<strong>at</strong>ing oil, grease dirt, radi<strong>at</strong>or coolants, sludge<br />

and certain chemicals. (CARDIUM & SEWAGE)<br />

1.2 Car body filter cleaning plants<br />

Pollutant discharged consists of lubric<strong>at</strong>ing oil, dirt and cleaning agents etc.<br />

1.3 Loco Components cleaning plants<br />

Pollutants discharge consists of oil, cleaning agents, sludge, dirt, metallic corroded<br />

metal flakes etc.<br />

1.4 Loco Washing<br />

Pollutant consists of detergent solution, oil, grease, dirt, lubric<strong>at</strong>ing oil sludge etc.<br />

1.5 Load Box<br />

Pollutants mainly consist of w<strong>at</strong>er, sludge, oil etc.<br />

1.6 Office Block / Canteen / DM Plant / Compressor<br />

Pollutants mainly w<strong>at</strong>er, sludge, oil, sewage sludge etc. including some chemicals.<br />

1.6.1 Discharge from Labor<strong>at</strong>ory<br />

Miscellaneous Lab chemicals, oil etc discharge in small quantities as pollutants.<br />

The contractor must ensure suitable provision of collecting effluent from<br />

different identified sources. It may necessit<strong>at</strong>e repair, extension of the existing drainage<br />

system etc.<br />

2. Setting up required effluent system :<br />

The effluent tre<strong>at</strong>ment system is expected to tre<strong>at</strong> an estim<strong>at</strong>ed 100 KL of<br />

pollutant w<strong>at</strong>er per day. Arrangement for setting of silt / sludge etc from the drain w<strong>at</strong>er<br />

should be ensured before entering oil w<strong>at</strong>er separ<strong>at</strong>or unit having capacity to<br />

accumul<strong>at</strong>e silt/sludge approxim<strong>at</strong>e 20 Cu.Mtrs.<br />

3. Expected Parameters of effluent <strong>at</strong> output<br />

Suitable arrangement for Physical / Chemical / Biological tre<strong>at</strong>ment of effluent<br />

flowing out of oil w<strong>at</strong>er separ<strong>at</strong>or, so as to achieve effluent level in final discharge as<br />

mentioned in Para 4.<br />

4. Parameters of effluent output<br />

Suitable arrangement to be provided for Physical / Chemical tre<strong>at</strong>ment of<br />

effluent to achieve effluent level in final discharge as indic<strong>at</strong>ed below:<br />

Sl. No.<br />

Parameters<br />

(AS PER TESTING<br />

REPORT OF HBTI<br />

CNB DATED<br />

23/02/2004) Present<br />

level after OWS<br />

Desired level<br />

after tre<strong>at</strong>ment in<br />

ETP<br />

Unit<br />

1 PH 8.4 5.5 – 9.0 Mg/Ltr<br />

2 TDS 628 ≤ 2100 Mg/Ltr<br />

3 TSS 70 ≤ 100 Mg/Ltr<br />

4 BOD 46 ≤ 30 Mg/Ltr

Page 15 of 34<br />

5 COD 64 ≤ 250 Mg/Ltr<br />

6 Oil & Grease 110 ≤ 10 Mg/Ltr<br />

7 Cr (IV) NIL NIL Mg/Ltr<br />

These figures are the result of testing of a sample of shed’s effluent checked <strong>at</strong><br />

out side labor<strong>at</strong>ory and may vary according to discharge from time to time.<br />

Contractor may collect the effluent samples desired for its own s<strong>at</strong>isfaction and<br />

as well as for designing of Effluent Tre<strong>at</strong>ment Plants.<br />

Existing arrangements:<br />

1. Diesel shed Gonda is discharging about 1,00,000 litres (100 KL) of effluent w<strong>at</strong>er every<br />

day. This effluent flows to the oil w<strong>at</strong>er separ<strong>at</strong>or situ<strong>at</strong>ed in the diesel shed premises<br />

(Near the proposed <strong>site</strong> of effluent tre<strong>at</strong>ment plant) where oil is removed to gre<strong>at</strong> extant<br />

by gravity separ<strong>at</strong>ion system. The effluent being routed through this oil w<strong>at</strong>er separ<strong>at</strong>or<br />

tank, is to be tre<strong>at</strong>ed to achieve effluent level in final discharge as indic<strong>at</strong>ed in the<br />

schedule of work and is also acceptable to UP Pollution Control Board in reference to<br />

their relevant parameters.<br />

2. The tre<strong>at</strong>ed w<strong>at</strong>er is to be stored suitably for cleaning purpose etc. remaining portion is<br />

to be disposed off by connecting with the city drain.<br />

3. The effluent tre<strong>at</strong>ment plant (ETP) shall consists of the following:<br />

Silt / sludge / collection arrangement / tank.<br />

Effluent collection / equaliz<strong>at</strong>ion tank.<br />

Reaction tank.<br />

Dosing tank.<br />

Neutralizing system.<br />

Clarific<strong>at</strong>ion system.<br />

Aer<strong>at</strong>ion system.<br />

Sludge drying beds.<br />

Oil separ<strong>at</strong>or for free / emulsified oils. (The existing OWS can also be used;<br />

addition/alter<strong>at</strong>ion if any deemed necessary may be made).<br />

• Office cum Control panel/oper<strong>at</strong>ors room; Labor<strong>at</strong>ory testing bench etc.<br />

provision should be made.<br />

<strong>Design</strong> details provided by the shed:<br />

Any details provided are given for general guidance showing our requirements. The<br />

firm may suitably decide the technique & design of the plant keeping in view to our<br />

requirements. The plant shall be simple economical to oper<strong>at</strong>e and shall have integr<strong>at</strong>ed control<br />

facility such th<strong>at</strong> deputing only one person for max. one shift is sufficient to oper<strong>at</strong>e the plant<br />

in a day ( Day shift only). The requirement of consumables shall be minimum for the working<br />

of the plant and its details shall be given in the offer clearly and elabor<strong>at</strong>ely.<br />

Survey of Effluent Tre<strong>at</strong>ment <strong>site</strong> of Gonda Diesel Shed :<br />

The tenderer or his represent<strong>at</strong>ive should visit Diesel Locomotive shed/Gonda. Prior to<br />

submitting the tender and study the <strong>site</strong> of the proposed effluent tre<strong>at</strong>ment plant <strong>at</strong> the available<br />

existing oil & w<strong>at</strong>er separ<strong>at</strong>or tank (OWS) and drainage system etc. for proper assessment of<br />

the work.

Page 16 of 34<br />

5. Provision for oil collection in 210 Ltrs. barrel<br />

The effluent tre<strong>at</strong>ment system will separ<strong>at</strong>e w<strong>at</strong>er oil /grease etc. through the OWS.<br />

The provision of mechanized collecting of this oil in 210 ltr barrel with minimum manual<br />

labour should be arranged. However empty 210 ltr barrels will be provided free of cost for<br />

collecting oil and oil should be handed over to SSE/Gen for further disposal.<br />

NOTE :- All by products from the plants must be non polluting and should be acceptable<br />

by the UPPCB/Lucknow.(AS PER LATEST NORMS)<br />

6. <strong>Commissioning</strong> and approval / certific<strong>at</strong>ion of the effluent tre<strong>at</strong>ment system<br />

6.1 Once the consent to oper<strong>at</strong>e the plant received from U.P. Pollution Control Board<br />

(UPPCB) and the plant has been handed over to Sr. DME/DSL/Gonda and the acceptance<br />

tests have been completed successfully. The plant shall be tre<strong>at</strong>ed as commissioned. The<br />

charges for obtaining consent to oper<strong>at</strong>e the plant from UPPCB will have to be borne the<br />

tenderer.<br />

6.2 The effluent tre<strong>at</strong>ment plant after commissioning will be run by the firm a period of six<br />

months. During this period tre<strong>at</strong>ed effluent samples will be sent to Uttar Pradesh<br />

Pollution Control Board or their approved lab for testing <strong>at</strong> an interval of 15 days. The<br />

charges for these tests will have to be borne by the tenderer. The results given by the<br />

Uttar Pradesh Pollution Control Board will be scrutinized and only after s<strong>at</strong>isfactory<br />

results obtained as per Uttar Pradesh Pollution Control Boards general standard for<br />

discharged pollutants (Into inland surface w<strong>at</strong>er) in consonance to EPA-86, the plant will<br />

be tre<strong>at</strong>ed finally commissioned.<br />

6.3 The tenderer should carefully read all the conditions about the n<strong>at</strong>ure of work involved as<br />

per technical specific<strong>at</strong>ion and schedule of work. The tenderer must give detailed<br />

brochures on the items offered by them including technical details etc.<br />

6.4 In case of devi<strong>at</strong>ions from the specified schedules merits of the items offered by them<br />

over the specified schedules should be worked out and submitted along with the offer.<br />

6.5 The work shall be completed with in 120 days from the d<strong>at</strong>e of communic<strong>at</strong>ion of<br />

acceptance of tender. However the tenderers must quote the delivery schedules.<br />

6.6 The firm will supply all consumables and provide necessary manpower etc. to run the<br />

plant during these periods. Electrical charges will be borne by the Railway.<br />

7. Penalty for delay in commissioning:<br />

The contractor or his agent shall commission the Effluent tre<strong>at</strong>ment plant with in the<br />

stipul<strong>at</strong>ed time as shown in the contract. This time frame will be applicable from the d<strong>at</strong>e of<br />

issue of work order after signing the agreement.<br />

The time allowed for commissioning of the plant by the contractor or his agent shall<br />

be deemed to be clearance of contract. In case of delay in commissioning of the plant on<br />

the part of the contractor, the purchaser shall be entitled to recover and the contractor shall<br />

be liable to pay liquid<strong>at</strong>ed damages <strong>at</strong> the r<strong>at</strong>e of 1½% of the total contract value for each<br />

and every month or part thereof for which commissioning is delayed. Provided always th<strong>at</strong><br />

the entire amount of liquid<strong>at</strong>ed damages to be paid under the provisions of this clause shall<br />

not exceed 6% of the total contract value.

Page 17 of 34<br />

Continuance of commissioning or after expiry of stipul<strong>at</strong>ed time will also not absolve<br />

the contractor from penalty as st<strong>at</strong>ed above. The decision of the Sr. DME/DSL/NER/Gonda<br />

whether the delay in commissioning has taken place on account of reason <strong>at</strong>tributed by the<br />

contractor shall be final and binding upon the contractor.<br />

8. Plant oper<strong>at</strong>ion for 06months:<br />

Contractor will make necessary arrangements to maintain and run the plant for a<br />

period of 06 months from the d<strong>at</strong>e of receiving consent to oper<strong>at</strong>e from UPPCB. During<br />

this period contractor will make arrangement of labour, m<strong>at</strong>erial, maintenance and other<br />

consumables necessary to run the plant and shall collect and deposit all separ<strong>at</strong>ed oil base<br />

pollutants with Sr. Section Engineer/Gen/Diesel/Gonda and dispose off all sludge /<br />

chemical refuse in a manner not objectionable to UPPCB / Municipal Corpor<strong>at</strong>ion Gonda<br />

& Gonda Diesel Shed.<br />

The firm will supply all consumables and provide manpower to run the plants during<br />

this period. Electrical charges will be borne by the railways as well empty drum will be<br />

provided free of cost of collection of oil.<br />

9. Training of Staff for oper<strong>at</strong>ion of the system:<br />

The firm will train the Diesel shed staff to run the plant during the erection, trial run,<br />

commissioning period and 06 months running period and all trained staff must be given<br />

certific<strong>at</strong>e clearly certifying their ability and skill to oper<strong>at</strong>e the plant. (NUMBER OF<br />

STAFF TRAINED SHOULD BE ATLEAST TWICE THE NUMBER REQUIRED TO<br />

OPERATE THE PLANT AT ANY GIVEN TIME).<br />

A. Handling over the Plant for oper<strong>at</strong>ion:<br />

On completion of the 06 months periods, the contractor will hand over the plant for<br />

oper<strong>at</strong>ion to the trained personnel of the Diesel Shed for routine oper<strong>at</strong>ion.<br />

B. Optional Scope of Work:<br />

The following details d<strong>at</strong>a should be provided by the tenderer for a detailed evalu<strong>at</strong>ion of<br />

the running costs of the plant. The d<strong>at</strong>a would also be used for extending the scope of work.<br />

1. Running Contract :<br />

Firm should quote for running the plants for one year as an additional option.<br />

2. Labour Cost :<br />

The labour cost in terms of man hours and also in estim<strong>at</strong>ed wages should be specified<br />

for oper<strong>at</strong>ion of plant.<br />

3. Cost of consumables :<br />

The quantity, r<strong>at</strong>es and the cost (For Gonda Shed) consumables required for oper<strong>at</strong>ion<br />

of plant will be given by the tenderer.<br />

4. Electricity Charges :<br />

Electricity will be supplied free of cost, however the total load of the plant and energy<br />

consumption should be shown separ<strong>at</strong>ely.<br />

5. Others Miscellaneous expenses :<br />

Any other expenses envisaged in oper<strong>at</strong>ion of the plant for a period of one year should<br />

also be quoted.

6. Post warranty maintenance<br />

Page 18 of 34<br />

The tenderer should quote separ<strong>at</strong>ely for post warranty maintenance charges for 5<br />

subsequent years in their offer for effluent tre<strong>at</strong>ment plant. However the Senior<br />

Divisional Mechanical Engineer/Diesel, Gonda may place a separ<strong>at</strong>e contract for this<br />

work as may be necessary every year.<br />

7. Land Fill <strong>site</strong> :<br />

The tenderer should quote separ<strong>at</strong>ely for complete turn key work of “Land fill <strong>site</strong>”<br />

with or without ETP as an additional ‘OPTION” as per specific<strong>at</strong>ion approved by UP<br />

Pollution Control Board of adequ<strong>at</strong>e size & capacity for storing/collecting by products,<br />

sludge and other solid mass after tre<strong>at</strong>ment.

SPECIAL CONDITION OF CONTRACT<br />

Page 19 of 34<br />

SECTION-IV<br />

1.0 <strong>Commissioning</strong> :<br />

The effluent tre<strong>at</strong>ment plant after commissioning will be run by the Tenderer for a<br />

period of 06 months and during this period tre<strong>at</strong>ed effluent samples will be sent to UP<br />

Pollution Control Board / Central Pollution Control Board <strong>at</strong> an interval of 15 days (The<br />

charges for these test will have to borne by the tenderer). The result given by the UPPCB with<br />

their certific<strong>at</strong>es will be scrutinized and only after the s<strong>at</strong>isfactory results as per UPPCB<br />

General Standards for discharging pollutant for (in land surface w<strong>at</strong>er) in consonance to EPA-<br />

86 in General conforming to Bureau of Indian Standards l<strong>at</strong>est version. The plant will be<br />

tre<strong>at</strong>ed as commissioned.<br />

During this period the firm will supply all the consumables and staff to run the plant.<br />

During the trial period tre<strong>at</strong>ment for disposal of sludge / waste arising from effluent tre<strong>at</strong>ment<br />

plant shall have to be done by the tenderer in accordance to the st<strong>at</strong>utory requirement of the<br />

Central and St<strong>at</strong>e Pollution Control Boards.<br />

2.0 Running Contract :<br />

Firm may also quote running the plant for one year (after commissioning of Effluent<br />

Tre<strong>at</strong>ment Plants and its acceptance) as an additional option, in running cost the details should<br />

be –<br />

Labour cost<br />

Cost of consumables<br />

Other miscellaneous expenses should be shown separ<strong>at</strong>ely.<br />

3.0 Turn Key Project :<br />

The tenderer is required to carry out the work of ETP as a turn key project and all civil,<br />

electrical, mechanical piping works along with the provision of required machinery & plant is<br />

to be done by the Tenderer.<br />

The tender shall contain complete details about the ETP offered by the tenderer along<br />

with reference to our requirements as per Section II, III & IV.<br />

The tenderer shall submit complete procedure for running, oper<strong>at</strong>ion and maintenance<br />

of the ETP offered by them in detail and elabor<strong>at</strong>e manner, along with details about the<br />

consumables required in the plant.<br />

Tenderer shall submit detailed drawing of the plant offered by them (in respect to the<br />

<strong>site</strong> proposed by the Railway for the ETP) showing clearly the system of the tre<strong>at</strong>ment, layout<br />

of the equipment’s, area covered and details of all engineering works th<strong>at</strong> would be done. The<br />

total space requirement shall be given in form of a lay out plan.<br />

Quality of Equipment used :<br />

For efficient and trouble free running of the plant. The mechanical and electrical<br />

equipments fitted in the plant such as pumps motors, pressure gauges, pipe lines, valves,<br />

starters, agit<strong>at</strong>ors, tanks etc. should be of reputed make preferable ISO firms and of ISI mark<br />

and fully confirming to the relevant IS specific<strong>at</strong>ion Firm’s name, specific<strong>at</strong>ions of Bureau of<br />

Indian Standards or of other institutions should be provided as reference for each of the<br />

equipment fitted in the plant as a part of the offer.<br />

Technical Liter<strong>at</strong>ure and Document<strong>at</strong>ion:<br />

The successful tenderer will provide the following technical liter<strong>at</strong>ure in <strong>at</strong> least two hard<br />

copy sets.<br />

• Maintenance/oper<strong>at</strong>ing Manuals and specific<strong>at</strong>ions of each of components items shall have<br />

to be supplied to this shed by the successful tenderer.<br />

• All drawings, flow sheet diagrams.

Page 20 of 34<br />

• Details of parameters of Electronics/Electrical/Mechanical appliances used in the plant.<br />

• Addresses of the OEM’s and the suppliers of the equipment fitted in the plant. This should<br />

also be supplied in the form of a Bill of m<strong>at</strong>erials in MS Excel, MS Access form<strong>at</strong>s on<br />

suitable electronic media.<br />

<strong>Supply</strong> of Spares :<br />

The firm shall have to ensure th<strong>at</strong> spares for the maintenance of this plant and the<br />

equipment fitted there in are supplied (on payment basis) to the Diesel Shed as and when<br />

required for a minimum period of five years after the expiry of the warranty period.<br />

Electrical Works :<br />

Contactor shall have to carry out the work of laying of electrical cables for all the<br />

electrical work involved in the ETP. Diesel shed will provide incoming electrical supply <strong>at</strong> the<br />

MCTB. Tenderer will have to supply all the electrical controls, energy meters, bus bars etc. for<br />

oper<strong>at</strong>ing the plants. The firm will have to supply the m<strong>at</strong>erial as per list enclosed <strong>at</strong> annexure<br />

B1 & B2.<br />

Civil Works :<br />

Tenderer will have to carry out all civil engineering works for all types of tanks and<br />

chambers etc. required in the plant as per standard specific<strong>at</strong>ion. They shall also submit<br />

detailed engineering drawings of all the engineering works of the plant certified by some<br />

qualified consultant.<br />

Sub-Contracted equipment :<br />

All the sub-Contracted equipment should be covered with a warranty for<br />

repair/replacement. Manuals & sources of spares required for the maintenance of these<br />

equipment should also be supplied for all sub-contracted equipment.<br />

Warranty :<br />

All the items / equipments fitted and all the works done in the plant must be under<br />

warranty for a minimum period of 24 months from the d<strong>at</strong>e of commissioning and the final<br />

acceptance of the plant. During this period the contractor is liable to arrange for immedi<strong>at</strong>e<br />

repairs/replacement of the defective parts/equipment free of cost and put the equipment in to<br />

normal working order within 03 days from the d<strong>at</strong>e of sending inform<strong>at</strong>ion to the contractor.<br />

Such replacement shall further carry a warranty of two year and a half from the d<strong>at</strong>e of<br />

replacement/repair.<br />

Acceptance Test :<br />

Tender is required to submit the details of the test procedures to be followed for<br />

commissioning and oper<strong>at</strong>ion of the effluent tre<strong>at</strong>ment plants <strong>at</strong> the <strong>site</strong> of install<strong>at</strong>ion<br />

indic<strong>at</strong>ing the dur<strong>at</strong>ion of the test period and shall warranty an average up time efficiency of<br />

90% for the dur<strong>at</strong>ion of the test period.<br />

The scope details, dur<strong>at</strong>ion and extension if any of the acceptance shall be discussed<br />

and mutually agreed upon between the purchaser and the contractor.<br />

On receipt of the advice from the contractor th<strong>at</strong> the system has been installed and is<br />

ready for acceptance test, one acceptance test of the effluent tre<strong>at</strong>ment plant shall be conducted<br />

by the contractor in the presence of Sr. Divisional Mechanical Engineer (Diesel)/N.E. Railway,<br />

Gonda or his authorized represent<strong>at</strong>ive.<br />

The contractor <strong>at</strong> his own cost shall provide any special equipment and tools required<br />

for the acceptance test. Railways will provide necessary electric power free of cost to enable<br />

the contractor to carry out this test. The test shall be conducted as stipul<strong>at</strong>ed here under.<br />

The contractor shall maintain necessary log book in respect of the result of the test to<br />

establish entire s<strong>at</strong>isfaction of the purchaser, the successful completion of the test specified.<br />

Page 21 of 34

On successful completion of the acceptance test and after meeting condition as<br />

specified in schedule of work and the purchaser is s<strong>at</strong>isfied with the working of the plant. The<br />

acceptance certific<strong>at</strong>e, signed by both the contractor and the represent<strong>at</strong>ive of Sr. Divisional<br />

Mechanical Engineer (Diesel)/N.E. Railway, Gonda will be issued. The d<strong>at</strong>e on which such<br />

certific<strong>at</strong>e is issued shall be deemed to be the d<strong>at</strong>e of commissioning of the plant.<br />

Should the contractor not successfully complete the acceptance test within the specified<br />

period. The dur<strong>at</strong>ion of these tests shall be extended for a further period as mutually agreed<br />

upon and in case of failure the Sr. Divisional Mechanical Engineer (Diesel)/N.E. Railway,<br />

Gonda shall reject the plant. The provisions contained in the Indian Railway, General<br />

conditions of contracts pertaining to consequences of rejection shall in th<strong>at</strong> case apply.<br />

The decision of Sr. Divisional Mechanical Engineer (Diesel)/N.E. Railway, Gonda<br />

regarding extension of d<strong>at</strong>es and result of the acceptance test shall be final and binding on the<br />

contractor.<br />

Payment Terms :<br />

80% of the total value will be released within 45 days from the d<strong>at</strong>e of commissioning<br />

the effluent tre<strong>at</strong>ment plant. Contractor should submit 80% bill in triplic<strong>at</strong>e in the name of<br />

Senior Divisional Mechanical Engineer (Diesel)/N.E. Railway, Gonda after successful<br />

install<strong>at</strong>ion and commissioning of Effluent Tre<strong>at</strong>ment Plant.<br />

10% payment shall be released after successful oper<strong>at</strong>ion after commissioning. Balance<br />

10% payment shall be released on submission of Bank Guarantee of equivalent value for a<br />

period of 18 months (covering the warranty period) from the d<strong>at</strong>e of successful commissioning<br />

of the effluent tre<strong>at</strong>ment plant for the working performance.<br />

No advance payment will be made for any supply of equipment. Firms particip<strong>at</strong>ing in<br />

the tender must agree to our payment terms.<br />

Credentials :<br />

The tenderer should be well established, experienced, reputed and registered with<br />

respective Pollution Control Boards with credibility to carry out similar type of work i.e. on oil<br />

base ETP systems and of tackling more than 100 KL effluent per day successfully in the past<br />

with this kind of technology certific<strong>at</strong>e to this effect, if any, may be enclosed.<br />

The tenderer should be in this field for <strong>at</strong> least three years. Experience earlier than the<br />

last three years shall not be considered. The tender must be supported with documents showing<br />

particulars of similar works, if any Carried out successfully for the Railways and other<br />

Government or Semi Govt. Organiz<strong>at</strong>ion.<br />

Tenderer(s) should have completed <strong>at</strong> least one similar single work for a minimum<br />

value of 35% of advertised tender value in last three financial years i.e. current year 3 previous<br />

financial years.<br />

Tenderer(s) should have received total contractual amount against s<strong>at</strong>isfactory<br />

execution/ work in progress of all type works for a minimum of 150% of advertised tender<br />

value of work during last three financial year and current financial year as per payment<br />

certific<strong>at</strong>e from the tenderer duly issued by the officers of concern government department or<br />

audited balance sheet duly certified by charted accountant.<br />

(ALSO ATLEAST ONE OF THE OWNER OF THE FIRM SHOULD BE A QUALIFIED<br />

ENGINEER)<br />

Undertaking by the tenderer for special conditions:<br />

I / we have read and understood the special conditions of this tender and hereby agree<br />

to abide by them and also agree to work in accordance to these special conditions.<br />

(Sign<strong>at</strong>ure of the tenderer)<br />

D<strong>at</strong>e : Tenderer’s Address :<br />

Place :

GENERAL CONDITIONS<br />

Page 22 of 34<br />

SECTION- V<br />

Priority of Condition of Contract<br />

The conditions of contract mentioned in this document are applicable as per the following<br />

priority:<br />

1. Special condition of contract.<br />

2. General condition of contracts of Indian railways. In case of any ambiguity or dual<br />

definition of the condition of contract the conditions specified in the higher priority<br />

would be applicable.<br />

Tender documents :<br />

The tenderer should carefully read <strong>at</strong> the conditions about the n<strong>at</strong>ure of work involved<br />

as per technical specific<strong>at</strong>ion and schedule of work. The tenderer must give detailed brochures<br />

on the items offered by them including technical details etc.<br />

In case of devi<strong>at</strong>ion from the specified schedule of merit of the item offered by them<br />

over the specified schedules should be worked out and submitted along with the offer.<br />

The work shall be completed with in 120 days from the d<strong>at</strong>e of communic<strong>at</strong>ion of<br />

acceptance of the tender. However the tender must quote the delivery schedule.<br />

The following documents should be specified for submission along with tender:<br />

(a) List of Personnel, organiz<strong>at</strong>ion available on hand and proposed to be engaged for the<br />

subject work.<br />

(b) List of plant and machinery available on hand (OWN) and proposed to be inducted<br />

(own and hire to be separ<strong>at</strong>ely) for the subject work.<br />

(c) List of works completed in the last three financial years giving description of work,<br />

organiz<strong>at</strong>ion whom executed approx value of contract and time of award d<strong>at</strong>e of award<br />

and schedule period of completion of work. D<strong>at</strong>e of actual completion and final value<br />

of contract may also be given.<br />

(d) List of works on hand indic<strong>at</strong>ing description of the contract value, approxim<strong>at</strong>e value of<br />

balance yet to be done and d<strong>at</strong>e of Award.<br />

Over writing on tender documents :<br />

No over writing in the r<strong>at</strong>e or tender schedule will be permitted. If r<strong>at</strong>es are to be<br />

changed, the alter<strong>at</strong>ion should be done by scoring the original r<strong>at</strong>e and re-writing the revised<br />

r<strong>at</strong>es initialling thereof. The administr<strong>at</strong>ion reserves its right to accept the tender in whole or<br />

any part of reject any one or all items of the tender without assigning any reason, wh<strong>at</strong> so ever.<br />

Implic<strong>at</strong>ion of submission of Tender Documents<br />

The submission of the tender will be deemed to imply th<strong>at</strong> this memorandum and all<br />

documents enclosed have been studied and under stood and th<strong>at</strong> the tenderer is aware of the<br />

full scope of the work to be done and the condition affecting the exception. In token this<br />

tenderer himself or his authorized represent<strong>at</strong>ives signing the tender documents will be<br />

required to sign / initial on each of the tender documents including each and every page of the<br />

tender schedule <strong>at</strong> the bottom.<br />

Submission of Tender<br />

The tender is to be depo<strong>site</strong>d in tender box in a sealed cover address to :<br />

Senior Divisional Mechanical Engineer (Diesel)<br />

N.E. Railway, Diesel Locomotive Shed<br />

Gonda – 271002<br />

Phone / fax : 05262 – 260216<br />

E.mail : srdmegd@gmail.com

Page 23 of 34<br />

The envelop must bear the following details on top :<br />

Quot<strong>at</strong>ion for [ Name of Work ]<br />

Tender Number : [ Tender No. ]<br />

Tender opening d<strong>at</strong>e : [ Tender opening d<strong>at</strong>e ]<br />

Tender opening time : [ Tender opening time ]<br />

When tender is sent by post. It is the responsibility of the tenderer to ensure th<strong>at</strong> the<br />

tender should reach before the due d<strong>at</strong>e and time. Tenders reaching l<strong>at</strong>e on account of postal<br />

delay will not be accepted.<br />

Rejection of Tender :<br />

Tender will be liable to be rejected out right if :<br />

Tender is received after the schedule d<strong>at</strong>e and time.<br />

Not submitted on prescribed form.<br />

Unsigned by either the issuing authority and / or the authorized sign<strong>at</strong>ory.<br />

Not accompanied with requi<strong>site</strong> earnest money in acceptable form.<br />

Details of Sign<strong>at</strong>ory for Tender :<br />

While signing the tender papers, the tenderer should specify whether he is a sole<br />

proprietor or he is a partner or he is signing on behalf of the firm as an <strong>at</strong>torney. (In this case<br />

the power of <strong>at</strong>torney in prescribed form should be submitted). In case of partnership, a copy of<br />

partnership deed should also be furnished. The original should be kept ready as and when<br />

required for verific<strong>at</strong>ion.<br />

Quoting for r<strong>at</strong>es and taxes :<br />

The r<strong>at</strong>e must be filled both in words and figures and should be inclusive of all charges.<br />

(ie. Raw m<strong>at</strong>erial and labour charges etc.) Details of taxes levied should be shown separ<strong>at</strong>ely<br />

against the column of taxes if any. Railway will issue Form ‘D’ or Form III D for sales tax<br />

concessions of if desired by the tenderer.<br />

Penalty and Recovery :<br />

The contractor should complete whole of the work in all respects on or before the d<strong>at</strong>e<br />

fixed by the Railways or any authorized extension or thereof. The railway administr<strong>at</strong>ion is<br />

entitled to recover penalty.<br />

The contractor shall accept reduction in total amount payable to him by Railway administr<strong>at</strong>ion<br />

@ 1- ½ % per week of the contract value to the actual delay occurred on the part of the<br />

contractor and until the work shall have been completed under the contract and such reduction<br />

shall be accept by the Railway administr<strong>at</strong>ion in full s<strong>at</strong>isfaction in the contractor liability<br />

arising from delay only. The Railway administr<strong>at</strong>ion shall <strong>at</strong> his sole discretion, specify a time<br />

limit within which the unfinished portion of the work shall be completed. In the event of failure<br />

of the contractor , the Railway administr<strong>at</strong>ion shall be <strong>at</strong> liberty to take action in accordance<br />

with the provision in clause 62 of general conditions of contract 1999.<br />

Sub-Contracting :<br />

The contractor shall not sub-contract this contract or allow any person for any reason to<br />

become interested there in any manner. In the event of contractor sub-contracting Railway<br />

administr<strong>at</strong>ion shall be free to cancelled the contract under clause 61 of general condition of<br />

contracts and also to initi<strong>at</strong>e recovery of losses caused due to such cancell<strong>at</strong>ions. Sr. Divisional<br />

Mechanical Engineer (Diesel)/N.E. Railway, Gonda would asses the extent of these losses.<br />

Foreign Exchange :<br />

Railway administr<strong>at</strong>ion will make no arrangement for making available any Foreign<br />

exchange for this work, if any foreign exchange contents involved in the work.

Page 24 of 34<br />

Documentary Evidence of Experience:<br />

Certific<strong>at</strong>e regarding experience in the line of work for which this tender has been<br />

flo<strong>at</strong>ed and documentary proof of current financial st<strong>at</strong>us in the form of bank balance<br />

certific<strong>at</strong>e. Certified by bank authority should be submitted along with the tender form,<br />

preference will be given to those tenderers who have done similar projects for Indian Railways<br />

successfully.<br />

Transport M<strong>at</strong>erial :<br />

The contractor should make necessary arrangement to pick-up the m<strong>at</strong>erial up to the<br />

<strong>site</strong> of the work. No transport would normally be provided to the contractor.<br />

Income Tax Clearance Certific<strong>at</strong>e:<br />

Unless the tendering firm has been extended by the Commissioner of Income tax from<br />

the production of income tax clearance certific<strong>at</strong>e / income tax valid certific<strong>at</strong>e (Proof of the<br />

exemption should be produced along with their tender). They should submit their current ITCC<br />

along with the tender. They should confirm in their tender to the condition th<strong>at</strong> in the event of<br />

their tender being accepted no payment shall be made to them for the m<strong>at</strong>erial / work under the<br />

contract they should not make claim for any such payment unless and until their valid ITCC is<br />

produced.<br />

Earnest Money :<br />

(a) Condition of earnest money : The tenderer shall be required to deposit prescribed<br />

amount of earnest money as specified page no. – 3 of this document with standard for<br />

the due performance stipul<strong>at</strong>ion to keep his offer open till such d<strong>at</strong>e as specified and<br />

stipul<strong>at</strong>ed on page no. -3 of this render document. No adjustment of the earnest money<br />

submitted earlier tenders, including tender, which have already been accepted shall be<br />

done. The tenders received without the aforesaid earnest money shall be summarily<br />

rejected. The forms, in which such earnest money shall be depo<strong>site</strong>d, are as under.<br />

(b) Mode of payment of earnest money: The earnest money as stipul<strong>at</strong>ed in this tender<br />

document can be paid by tenderer in any one of the following forms and no other<br />

forms:<br />

(i) Deposit in cash with the Divisional Cashier, N.E. Railway, Gonda / Lucknow and to<br />

<strong>at</strong>tach the money receipt obtained thereof with this tender document.<br />

(ii) Deposit Receipts or Pay Orders or Demands Drafts from the St<strong>at</strong>e Bank of India or<br />

from of the N<strong>at</strong>ionalised Banks drawn in favour of Financial Adviser and Divisional<br />

Cashier, N.E. Railway, Gonda / Lucknow and duly endorsed as Account Payee and<br />

valid for a period of 6 (six) months from the d<strong>at</strong>e of opening of the tender.<br />

(c) Deposit Receipts executed by the Scheduled banks (other than the St<strong>at</strong>e Bank of India<br />

and the N<strong>at</strong>ionalised Banks) approved by the Reserve Bank of India for this purpose.<br />

Refund of Earnest Money :<br />

(a) Earnest money of unsuccessful tenderers shall, save as herein provided, be returned to<br />

them within a responsible time. However, the Railway shall neither be responsible for<br />

any loss or depreci<strong>at</strong>ion th<strong>at</strong> may happen thereto while in possession of the Railway nor<br />

it will be liable to pay interest thereon.<br />

(b) Earnest money depo<strong>site</strong>d in cash shall be refunded by a cheque drawn in favour of<br />

unsuccessful tenderers and shall be sent to them by Registered Post <strong>at</strong> the address given<br />

by them in this documents.<br />