Corporate responsibility report / Responsible brand - PKN Orlen

Corporate responsibility report / Responsible brand - PKN Orlen

Corporate responsibility report / Responsible brand - PKN Orlen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Environmental and social <strong>responsibility</strong><br />

Two accelerators (A-4 and A-5) from water decarbonisation<br />

process were used in the 3rd stage of wastewater<br />

treatment. Here it was possible to repeatedly use sediment<br />

from raw water decarbonisation process in wastewater<br />

coagulation process.<br />

Wastewater is used as industrial water for cleaning,<br />

washing and fire fighting purposes.<br />

The new technologies yielded environmental and economic<br />

benefits. The volume of water uptaken from and wastewater<br />

discharged to the Vistula has significantly dropped.<br />

However, the closed water circuit, apart from advantages,<br />

caused certain problems and restrictions. In 2000,<br />

we resigned from directing reversed wastewater to cooling<br />

systems, as it resulted in excessive salinity of water at water<br />

blocks. High salinity of circulating water made it necessary<br />

to desalt cooling systems and as a consequence caused<br />

increased ballast water discharge to the wastewater<br />

treatment plant. Thus, in order to be able to still use<br />

recycled water, we will have to reduce salt consumption<br />

in the water and wastewater system. Proposal to be applied<br />

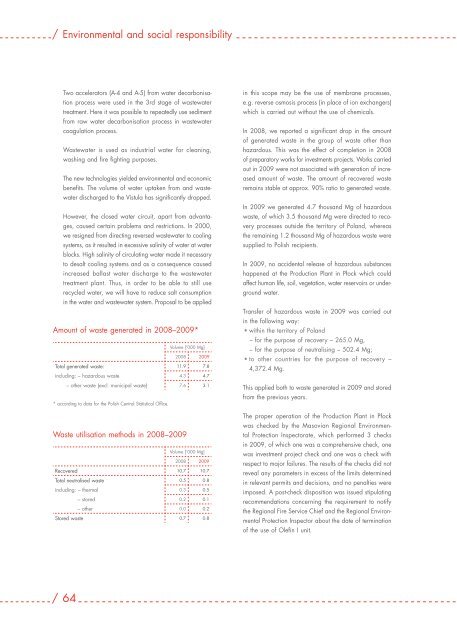

Amount of waste generated in 2008–2009*<br />

Volume [‘000 Mg]<br />

2008 2009<br />

Total generated waste: 11.9 7.8<br />

including: – hazardous waste 4.3 4.7<br />

– other waste (excl. municipal waste) 7.6 3.1<br />

* according to data for the Polish Central Statistical Office.<br />

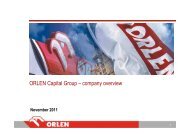

Waste utilisation methods in 2008–2009<br />

Volume [‘000 Mg]<br />

2008 2009<br />

Recovered 10.7 10.7<br />

Total neutralised waste 0.5 0.8<br />

including: – thermal 0.3 0.5<br />

– stored 0.2 0.1<br />

– other 0.0 0.2<br />

Stored waste 0.7 0.8<br />

in this scope may be the use of membrane processes,<br />

e.g. reverse osmosis process (in place of ion exchangers)<br />

which is carried out without the use of chemicals.<br />

In 2008, we <strong>report</strong>ed a significant drop in the amount<br />

of gene rated waste in the group of waste other than<br />

hazardous. This was the effect of completion in 2008<br />

of preparatory works for investments projects. Works carried<br />

out in 2009 were not associated with generation of increased<br />

amount of waste. The amount of recovered waste<br />

remains stable at approx. 90% ratio to generated waste.<br />

In 2009 we generated 4.7 thousand Mg of hazardous<br />

waste, of which 3.5 thousand Mg were directed to recovery<br />

processes outside the territory of Poland, whereas<br />

the remaining 1.2 thousand Mg of hazardous waste were<br />

supplied to Polish recipients.<br />

In 2009, no accidental release of hazardous substances<br />

happened at the Production Plant in Płock which could<br />

affect human life, soil, vegetation, water reservoirs or underground<br />

water.<br />

Transfer of hazardous waste in 2009 was carried out<br />

in the following way:<br />

• within the territory of Poland<br />

– for the purpose of recovery – 265.0 Mg,<br />

– for the purpose of neutralising – 502.4 Mg;<br />

• to other countries for the purpose of recovery –<br />

4,372.4 Mg.<br />

This applied both to waste generated in 2009 and stored<br />

from the previous years.<br />

The proper operation of the Production Plant in Płock<br />

was checked by the Masovian Regional Environmental<br />

Protection Inspectorate, which performed 3 checks<br />

in 2009, of which one was a comprehensive check, one<br />

was investment project check and one was a check with<br />

respect to major failures. The results of the checks did not<br />

reveal any parameters in excess of the limits determined<br />

in relevant permits and decisions, and no penalties were<br />

imposed. A post-check disposition was issued stipulating<br />

recommendations concerning the requirement to notify<br />

the Regional fire Service Chief and the Regional Environmental<br />

Protection Inspector about the date of termination<br />

of the use of Olefin I unit.<br />

/ 64