Oil and gas production handbook - Process Control and ...

Oil and gas production handbook - Process Control and ...

Oil and gas production handbook - Process Control and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

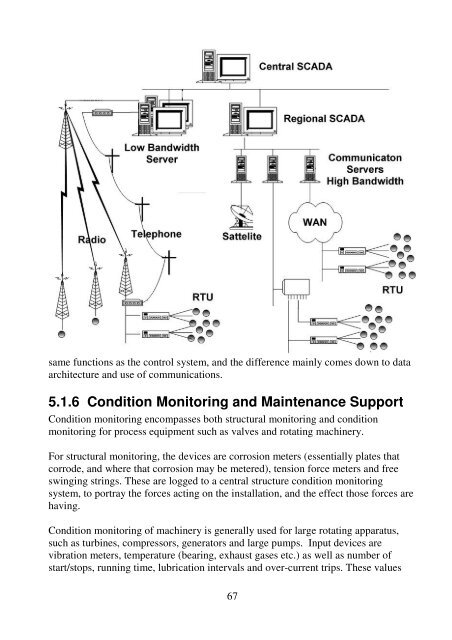

same functions as the control system, <strong>and</strong> the difference mainly comes down to data<br />

architecture <strong>and</strong> use of communications.<br />

5.1.6 Condition Monitoring <strong>and</strong> Maintenance Support<br />

Condition monitoring encompasses both structural monitoring <strong>and</strong> condition<br />

monitoring for process equipment such as valves <strong>and</strong> rotating machinery.<br />

For structural monitoring, the devices are corrosion meters (essentially plates that<br />

corrode, <strong>and</strong> where that corrosion may be metered), tension force meters <strong>and</strong> free<br />

swinging strings. These are logged to a central structure condition monitoring<br />

system, to portray the forces acting on the installation, <strong>and</strong> the effect those forces are<br />

having.<br />

Condition monitoring of machinery is generally used for large rotating apparatus,<br />

such as turbines, compressors, generators <strong>and</strong> large pumps. Input devices are<br />

vibration meters, temperature (bearing, exhaust <strong>gas</strong>es etc.) as well as number of<br />

start/stops, running time, lubrication intervals <strong>and</strong> over-current trips. These values<br />

67