CATALOGUE 201ME JANUARY 2004

CATALOGUE 201ME JANUARY 2004

CATALOGUE 201ME JANUARY 2004

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

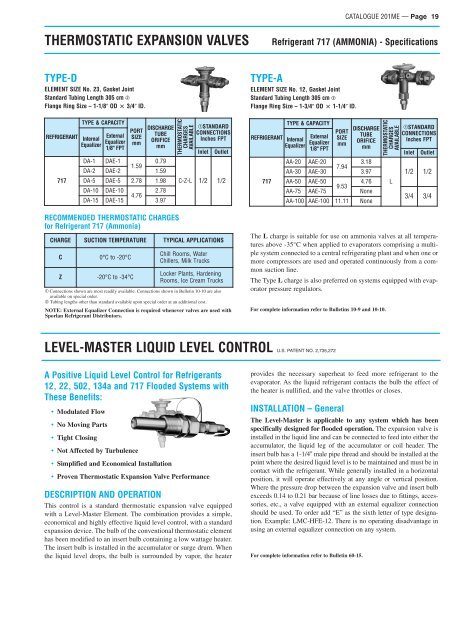

<strong>CATALOGUE</strong> <strong>201ME</strong> — Page 19<br />

THERMOSTATIC EXPANSION VALVES<br />

Refrigerant 717 (AMMONIA) - Specifications<br />

TYPE-D<br />

ELEMENT SIZE No. 23, Gasket Joint<br />

Standard Tubing Length 305 cm @<br />

Flange Ring Size – 1-1/8 OD 3/4 ID.<br />

REFRIGERANT<br />

717<br />

CHARGE<br />

TYPE & CAPACITY<br />

Internal<br />

Equalizer<br />

External<br />

Equalizer<br />

1/8" FPT<br />

PORT<br />

SIZE<br />

mm<br />

DISCHARGE<br />

TUBE<br />

ORIFICE<br />

mm<br />

DA-1<br />

DAE-1<br />

0.79<br />

1.59<br />

DA-2<br />

DAE-2<br />

1.59<br />

DA-5<br />

DAE-5<br />

2.78<br />

1.98<br />

DA-10<br />

DAE-10<br />

2.78<br />

4.76<br />

DA-15<br />

DAE-15<br />

3.97<br />

RECOMMENDED THERMOSTATIC CHARGES<br />

for Refrigerant 717 (Ammonia)<br />

SUCTION TEMPERATURE<br />

C 0° C to -20°C<br />

Z - 20° C to -34°C<br />

THERMOSTATIC<br />

CHARGES<br />

AVAILABLE<br />

! STANDARD<br />

CONNECTIONS<br />

Inches FPT<br />

Inlet<br />

Outlet<br />

C-Z-L<br />

1/<br />

2 1/ 2<br />

TYPICAL APPLICATIONS<br />

Chill Rooms, Water<br />

Chillers, Milk Trucks<br />

Locker Plants, Hardening<br />

Rooms, Ice Cream Trucks<br />

! Connections shown are most readily available. Connections shown in Bulletin 10-10 are also<br />

available on special order.<br />

@ Tubing lengths other than standard available upon special order at an additional cost.<br />

NOTE: External Equalizer Connection is required whenever valves are used with<br />

Sporlan Refrigerant Distributors.<br />

TYPE-A<br />

ELEMENT SIZE No. 12, Gasket Joint<br />

Standard Tubing Length 305 cm @<br />

Flange Ring Size – 1-3/4 OD 1-1/4 ID.<br />

REFRIGERANT<br />

717<br />

TYPE & CAPACITY<br />

Internal<br />

Equalizer<br />

External<br />

Equalizer<br />

1/8" FPT<br />

PORT<br />

SIZE<br />

mm<br />

DISCHARGE<br />

TUBE<br />

ORIFICE<br />

mm<br />

AA-20<br />

AAE-20<br />

3.18<br />

7.94<br />

AA-30<br />

AAE-30<br />

3.97<br />

AA-50<br />

AAE-50<br />

4.76<br />

9.53<br />

AA-75<br />

AAE-75<br />

None<br />

AA-100<br />

AAE-100<br />

11.11<br />

None<br />

L<br />

! STANDARD<br />

CONNECTIONS<br />

Inches FPT<br />

Inlet<br />

Outlet<br />

1/2<br />

1/ 2<br />

3/4<br />

3/ 4<br />

The L charge is suitable for use on ammonia valves at all temperatures<br />

above -35°C when applied to evaporators comprising a multiple<br />

system connected to a central refrigerating plant and when one or<br />

more compressors are used and operated continuously from a common<br />

suction line.<br />

The Type L charge is also preferred on systems equipped with evaporator<br />

pressure regulators.<br />

For complete information refer to Bulletins 10-9 and 10-10.<br />

THERMOSTATIC<br />

CHARGES<br />

AVAILABLE<br />

LEVEL-MASTER LIQUID LEVEL CONTROL U.S. PATENT NO. 2,735,272<br />

A Positive Liquid Level Control for Refrigerants<br />

12, 22, 502, 134a and 717 Flooded Systems with<br />

These Benefits:<br />

• Modulated Flow<br />

• No Moving Parts<br />

• Tight Closing<br />

• Not Affected by Turbulence<br />

• Simplified and Economical Installation<br />

• Proven Thermostatic Expansion Valve Performance<br />

DESCRIPTION AND OPERATION<br />

This control is a standard thermostatic expansion valve equipped<br />

with a Level-Master Element. The combination provides a simple,<br />

economical and highly effective liquid level control, with a standard<br />

expansion device. The bulb of the conventional thermostatic element<br />

has been modified to an insert bulb containing a low wattage heater.<br />

The insert bulb is installed in the accumulator or surge drum. When<br />

the liquid level drops, the bulb is surrounded by vapor, the heater<br />

provides the necessary superheat to feed more refrigerant to the<br />

evaporator. As the liquid refrigerant contacts the bulb the effect of<br />

the heater is nullified, and the valve throttles or closes.<br />

INSTALLATION – General<br />

The Level-Master is applicable to any system which has been<br />

specifically designed for flooded operation. The expansion valve is<br />

installed in the liquid line and can be connected to feed into either the<br />

accumulator, the liquid leg of the accumulator or coil header. The<br />

insert bulb has a 1-1/4 male pipe thread and should be installed at the<br />

point where the desired liquid level is to be maintained and must be in<br />

contact with the refrigerant. While generally installed in a horizontal<br />

position, it will operate effectively at any angle or vertical position.<br />

Where the pressure drop between the expansion valve and insert bulb<br />

exceeds 0.14 to 0.21 bar because of line losses due to fittings, accessories,<br />

etc., a valve equipped with an external equalizer connection<br />

should be used. To order add “E” as the sixth letter of type designation.<br />

Example: LMC-HFE-12. There is no operating disadvantage in<br />

using an external equalizer connection on any system.<br />

For complete information refer to Bulletin 60-15.