bauer - Zanshin

bauer - Zanshin

bauer - Zanshin

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BAUER<br />

COMPRESSORS<br />

Junior II, Yachting<br />

3.2.3 Telescope Intake Tube<br />

See Figure 3-2. The telescopic intake tube is inserted in the intake opening (5). This is necessary to<br />

ensure clean intake air on engine driven compressor units. It’s use is also recommended with electric<br />

motor driven compressor units.<br />

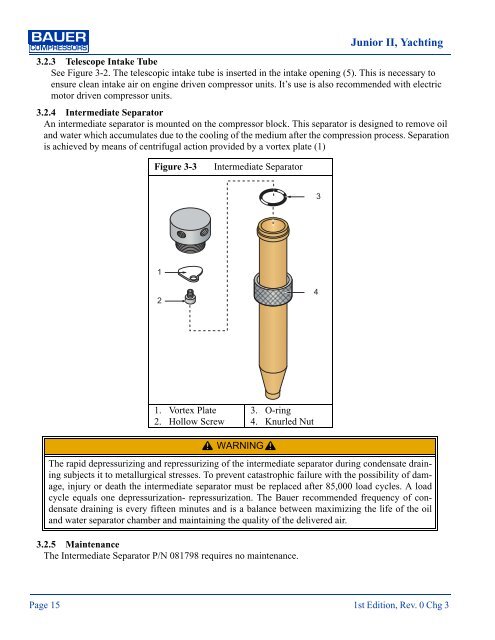

3.2.4 Intermediate Separator<br />

An intermediate separator is mounted on the compressor block. This separator is designed to remove oil<br />

and water which accumulates due to the cooling of the medium after the compression process. Separation<br />

is achieved by means of centrifugal action provided by a vortex plate (1)<br />

Figure 3-3<br />

Intermediate Separator<br />

3<br />

1<br />

2<br />

4<br />

1. Vortex Plate<br />

2. Hollow Screw<br />

3. O-ring<br />

4. Knurled Nut<br />

^ WARNING ^<br />

The rapid depressurizing and repressurizing of the intermediate separator during condensate draining<br />

subjects it to metallurgical stresses. To prevent catastrophic failure with the possibility of damage,<br />

injury or death the intermediate separator must be replaced after 85,000 load cycles. A load<br />

cycle equals one depressurization- repressurization. The Bauer recommended frequency of condensate<br />

draining is every fifteen minutes and is a balance between maximizing the life of the oil<br />

and water separator chamber and maintaining the quality of the delivered air.<br />

3.2.5 Maintenance<br />

The Intermediate Separator P/N 081798 requires no maintenance.<br />

Page 15 1st Edition, Rev. 0 Chg 3