ML193DF Gas Furnace Installation Manual - Lennox

ML193DF Gas Furnace Installation Manual - Lennox

ML193DF Gas Furnace Installation Manual - Lennox

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Gas</strong> Piping<br />

CAUTION<br />

If a flexible gas connector is required or allowed by<br />

the authority that has jurisdiction, black iron pipe<br />

shall be installed at the gas valve and extend outside<br />

the furnace cabinet. The flexible connector can then<br />

be added between the black iron pipe and the gas<br />

supply line.<br />

WARNING<br />

Do not exceed 600 in−lbs (50 ft−lbs) torque when attaching<br />

the gas piping to the gas valve.<br />

1 − <strong>Gas</strong> piping may be routed into the unit through either<br />

the left- or right-hand side. Supply piping enters into<br />

the gas valve from the side of the valve as shown in<br />

figure 47.<br />

2 − When connecting gas supply, factors such as length of<br />

run, number of fittings and furnace rating must be considered<br />

to avoid excessive pressure drop. Table 10<br />

lists recommended pipe sizes for typical applications.<br />

NOTE − Use two wrenches when connecting gas piping<br />

to avoid transferring torque to the manifold.<br />

3 − <strong>Gas</strong> piping must not run in or through air ducts, clothes<br />

chutes, chimneys or gas vents, dumb waiters or elevator<br />

shafts. Center gas line through piping hole. <strong>Gas</strong><br />

line should not touch side of unit. See figures 47.<br />

4 − Piping should be sloped 1/4 inch per 15 feet (6mm per<br />

5.6m) upward toward the gas meter from the furnace.<br />

The piping must be supported at proper intervals, every<br />

8 to 10 feet (2.44 to 3.05m), using suitable hangers<br />

or straps. Install a drip leg in vertical pipe runs to serve as<br />

a trap for sediment or condensate.<br />

5 − A 1/8" N.P.T. plugged tap or pressure post is located<br />

on the gas valve to facilitate test gauge connection.<br />

See figure 54.<br />

6 − In some localities, codes may require installation of a<br />

manual main shut-off valve and union (furnished by installer)<br />

external to the unit. Union must be of the<br />

ground joint type.<br />

IMPORTANT<br />

Compounds used on threaded joints of gas piping<br />

must be resistant to the actions of liquified petroleum<br />

gases.<br />

Leak Check<br />

After gas piping is completed, carefully check all piping<br />

connections (factory− and field−installed) for gas leaks. Use<br />

a leak detecting solution or other preferred means.<br />

The furnace must be isolated from the gas supply system<br />

by closing its individual manual shut-off valve during any<br />

pressure testing of the gas supply system at pressures less<br />

than or equal to 1/2 psig (3.48 kPa, 14 inches w.c.).<br />

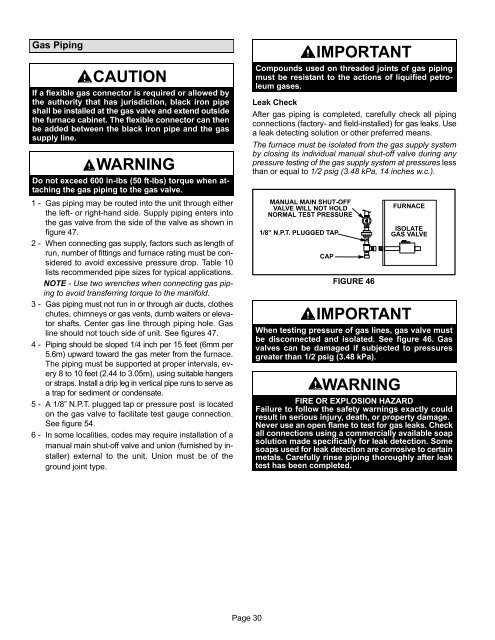

MANUAL MAIN SHUT−OFF<br />

VALVE WILL NOT HOLD<br />

NORMAL TEST PRESSURE<br />

1/8" N.P.T. PLUGGED TAP<br />

CAP<br />

FIGURE 46<br />

FURNACE<br />

ISOLATE<br />

GAS VALVE<br />

IMPORTANT<br />

When testing pressure of gas lines, gas valve must<br />

be disconnected and isolated. See figure 46. <strong>Gas</strong><br />

valves can be damaged if subjected to pressures<br />

greater than 1/2 psig (3.48 kPa).<br />

WARNING<br />

FIRE OR EXPLOSION HAZARD<br />

Failure to follow the safety warnings exactly could<br />

result in serious injury, death, or property damage.<br />

Never use an open flame to test for gas leaks. Check<br />

all connections using a commercially available soap<br />

solution made specifically for leak detection. Some<br />

soaps used for leak detection are corrosive to certain<br />

metals. Carefully rinse piping thoroughly after leak<br />

test has been completed.<br />

Page 30