You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

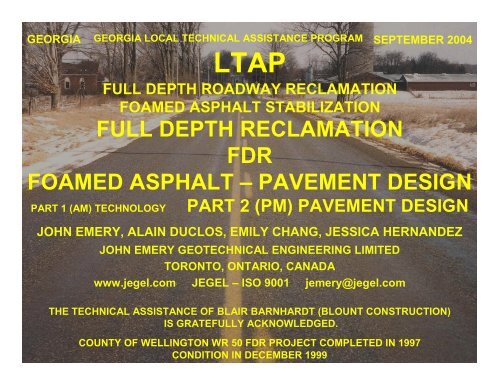

GEORGIA GEORGIA LOCAL TECHNICAL ASSISTANCE PROGRAM SEPTEMBER 2004<br />

LTAP<br />

FULL DEPTH RECLAMATION<br />

FDR<br />

FOAMED ASPHALT – PAVEMENT DESIGN<br />

PART 1 (AM) TECHNOLOGY<br />

FULL DEPTH ROADWAY RECLAMATION<br />

FOAMED ASPHALT STABILIZATION<br />

PART 2 (PM) PAVEMENT DESIGN<br />

JOHN EMERY, ALAIN DUCLOS, EMILY CHANG, JESSICA HERNANDEZ<br />

JOHN EMERY GEOTECHNICAL ENGINEERING LIMITED<br />

TORONTO, ONTARIO, CANADA<br />

www.jegel.com JEGEL – ISO 9001 jemery@jegel.com<br />

THE TECHNICAL ASSISTANCE OF BLAIR BARNHARDT (BLOUNT CONSTRUCTION)<br />

IS GRATEFULLY ACKNOWLEDGED.<br />

COUNTY OF WELLINGTON WR 50 FDR PROJECT COMPLETED IN 1997<br />

CONDITION IN DECEMBER 1999

FOAMED ASPHALT PART 1 CONCLUSIONS<br />

• ADVANTAGES<br />

– EASY APPLICATION<br />

– FLEXIBLE LAYER WITH GOOD RUTTING AND FATIGUE PROPERTIES<br />

– ECONOMIC (LCCA)<br />

– RAPID STRENGTH GAIN - ROAD CAN BE OPENED AFTER COMPACTION<br />

– REFLECTIVE CRACKING MITIGATION<br />

• DISADVANTAGES<br />

– REQUIRES A SUPPLY OF HOT (~160°C, 320°F PLUS) ASPHALT CEMENT<br />

– STABILIZED MATERIAL SHOULD HAVE 5 TO 15 PERCENT PASSING 75 µm<br />

• FOAMED (EXPANDED) ASPHALT STABILIZATION WELL ESTABLISHED, PROVEN<br />

AND COST EFFECTIVE<br />

• REFLECTIVE CRACKING MITIGATION<br />

• PROFILE CORRECTION AND SUPERELEVATION RESTORATION<br />

• RECOMMEND AGENCY EVALUATE PAVEMENT/SET PERFORMANCE<br />

SPECIFICATIONS AND ACCEPTANCE (QA)<br />

• RECOMMEND CONTRACTOR RESPONSIBLE FOR DESIGN/PROCESS/MATERIALS<br />

PERFORMANCE AND QUALITY CONTROL<br />

• RECOMMEND STABILIZATION PROCESS BE SEPARATE PAY ITEM<br />

• a 1 OF ~ 0.35 TO 0.40 FOR AASHTO SN (GBE OF ~ 1.8) FOR PROPERLY DESIGNED<br />

AND CONSTRUCTED FOAMED ASPHALT STABILIZATION (QUALITY VERY<br />

IMPORTANT)

FLEXIBLE PAVEMENT DESIGN<br />

THE QUALITY OF WORK PERFORMED<br />

DIRECTLY INFLUENCES THE USEFUL LIFE OF<br />

THE PAVEMENT, MAINTENANCE COSTS, LEVEL<br />

OF SERVICE AND USER COSTS<br />

CHALLENGING TIME FOR PAVEMENTS<br />

• INCREASING TRAFFIC VOLUMES AND TRUCK LOADINGS<br />

• LIMITED CAPITAL AND MAINTENANCE FUNDS<br />

• NETWORKS IN NEED OF MAINTENANCE AND IMPROVEMENT<br />

• MANY BRIDGES ARE DEFICIENT<br />

DON VALLEY PARKWAY IN TORONTO<br />

LONG-LIFE ASPHALT PAVEMENT – PERPETUAL PAVEMENT

PART 2<br />

F<br />

E<br />

E<br />

D<br />

B<br />

A<br />

C<br />

K<br />

INVENTORY<br />

INVENTORY<br />

FLEXIBLE PAVEMENT DESIGN<br />

INPUT<br />

INPUT<br />

INFORMATION<br />

INFORMATION<br />

PERFORMANCE<br />

PERFORMANCE<br />

CRITERIA<br />

CRITERIA<br />

PAVEMENT<br />

PAVEMENT<br />

MODELS<br />

MODELS<br />

PAVEMENT<br />

PAVEMENT<br />

SERVICEABILITY<br />

SERVICEABILITY<br />

PAVEMENT<br />

PAVEMENT<br />

MATERIALS<br />

MATERIALS<br />

PAVEMENT<br />

PAVEMENT<br />

DESIGN<br />

DESIGN<br />

NEW,<br />

NEW,<br />

OVERLAY,<br />

OVERLAY,<br />

REHABILITATION<br />

REHABILITATION<br />

CONSTRUCT<br />

CONSTRUCT<br />

PAVEMENT<br />

PAVEMENT<br />

OR<br />

OR<br />

OVERLAY<br />

OVERLAY<br />

PAVEMENT<br />

PAVEMENT<br />

OR<br />

OR<br />

REHABILITATE<br />

REHABILITATE<br />

PAVEMENT<br />

PAVEMENT<br />

SYSTEMATIC<br />

SYSTEMATIC<br />

PAVEMENT<br />

PAVEMENT<br />

MAINTENANCE<br />

MAINTENANCE<br />

MAINTENANCE<br />

MAINTENANCE<br />

MANAGEMENT<br />

MANAGEMENT<br />

SYSTEM<br />

SYSTEM<br />

PAVEMENT<br />

PAVEMENT<br />

MANAGEMENT<br />

MANAGEMENT<br />

SYSTEM<br />

SYSTEM<br />

PERFORMANCE<br />

PERFORMANCE<br />

MONITORING<br />

MONITORING<br />

SAFE,<br />

SAFE,<br />

SMOOTH,<br />

SMOOTH,<br />

SURFACES<br />

SURFACES<br />

HAPPY<br />

HAPPY<br />

CUSTOMERS<br />

CUSTOMERS<br />

LIFE-CYCLE COST ANALYSIS AND VALUE ENGINEERING<br />

• TRAFFIC (ESALs)<br />

•SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• BUDGET<br />

• RUTTING<br />

•FATIGUE<br />

• THERMAL<br />

•INITIAL<br />

•TERMINAL<br />

• PCI - PSR<br />

•IRI<br />

• SUBBASE<br />

• BASE<br />

• ASPHALT CONCRETE<br />

SUPERPAVE<br />

PGAC, VOLUMETRIC, PERFORMANCE<br />

•GBE<br />

• AASHTO 93<br />

• COMING SOON - AASHTO 2002<br />

• LCCA AND VE<br />

•QC<br />

•QA<br />

• CRACK SEALING<br />

• SUMMER MAINTENANCE<br />

• WINTER MAINTENANCE<br />

• PAVEMENT PRESERVATION<br />

• INVENTORY (DATA BANK)<br />

• MONITOR PERFORMANCE<br />

• NETWORK LEVEL<br />

• PROJECT LEVEL<br />

• BUDGET<br />

• WINTER SURFACE CONDITION<br />

• MOVING TO PMS/MMS/AMS<br />

•PERPETUAL FLEXIBLE PAVEMENTS

FLEXIBLE PAVEMENT DESIGN<br />

FLEXIBLE PAVEMENTS<br />

• STRONG<br />

• DURABLE<br />

• SMOOTH<br />

• SAFE<br />

• ECONOMIC<br />

HIGHWAY AND AIRPORT<br />

CITY OF TORONTO ROYAL YORK ROAD 1997 CIR PROJECT WITH HMA SURFACE<br />

CURRENT CONDITION

FLEXIBLE PAVEMENT DESIGN<br />

ASPHALT<br />

GRANLAR BASE OR FOAMED ASPHALT<br />

GRANULAR SUBBASE<br />

SUBGRADE<br />

TYPICAL PAVEMENT STRUCTURE

• PERFORMANCE CRITERIA<br />

– RUTTING AND FATIGUE<br />

• PAVEMENT DESIGN INPUT REQUIRED<br />

– TRAFFIC<br />

– SUBGRADE<br />

– DRAINAGE CONDITIONS<br />

- KEY TO PAVEMENT PERFORMANCE<br />

- DRAINAGE, DRAINAGE, DRAINAGE<br />

- TAKE THE WATER OUT, KEEP THE WATER OUT<br />

– ENVIRONMENTAL CONDITIONS<br />

– MATERIALS<br />

- GRANULAR MATERIALS<br />

- FOAMED ASPHALT<br />

- ASPHALT CONCRETE<br />

– SERVICEABILITY<br />

FLEXIBLE PAVEMENT DESIGN<br />

- INITIAL AND TERMINAL

FLEXIBLE PAVEMENT DESIGN<br />

• PERFORMANCE CRITERIA<br />

RUTTING<br />

TOTAL PAVEMENT - SUBGRADE, GRANULAR SUBBASE,<br />

GRANULAR BASE, FOAMED ASPHALT AND/OR ASPHALT<br />

CONCRETE<br />

FATIGUE<br />

ASPHALT CONCRETE AND FOAMED ASPHALT

FLEXIBLE PAVEMENT DESIGN<br />

CRITICAL STRAINS FOR MECHANISTIC ANALYSIS<br />

HORIZONTAL STRAIN AT BOTTOM<br />

OF ASPHALT CONCRETE<br />

OR FOAMED ASPHALT<br />

VERTICAL STRAIN AT TOP OF SUBGRADE

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

•TRAFFIC<br />

TYPE, MASS AND NUMBER (AADT)<br />

ESALs

• TRAFFIC<br />

• SUBGRADE<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

BOREHOLE INVESTIGATION<br />

CBR TESTING<br />

LABORATORY MR TESTING<br />

DYNAMIC CONE PENETROMETER TESTING<br />

FWD TESTING<br />

PARTICULARLY FOR REHABILITATION

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT EVALUATION<br />

• VISUAL CONDITION SURVEY<br />

• CORING/BOREHOLE INVESTIGATION TO DETERMINE THE<br />

THICKNESS OF THE ASPHALT CONCRETE PAVEMENT<br />

LAYER(S) AND GRANULAR BASE/SUBBASE AND TO OBTAIN<br />

SAMPLES FOR LABORATORY TESTING<br />

• FALLING WEIGHT DEFLECTOMETER (FWD) LOAD/DEFLECTION<br />

TESTING TO DETERMINE THE STRUCTURAL CAPACITY OF<br />

THE PAVEMENT<br />

• LABORATORY TESTING OF MATERIALS OBTAINED ON SITE<br />

• EMPIRICAL OR MECHANISTIC-EMPIRICAL PAVEMENT<br />

STRUCTURE ANALYSIS (DESIGN)<br />

IS THIS A SUITABLE SECTION FOR FOAMED ASPHALT<br />

•DRAINAGE?<br />

•STRUCTURAL ADEQUACY? FWD

• TRAFFIC<br />

• SUBGRADE<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• DRAINAGE CONDITIONS<br />

KEY TO PAVEMENT PERFORMANCE<br />

1. DRAINAGE<br />

2. DRAINAGE<br />

3. DRAINAGE<br />

TAKE THE WATER OUT. KEEP THE<br />

WATER OUT.

FLEXIBLE PAVEMENT DESIGN<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

IMPROVE OR INSTALL AS NECESSARY

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL<br />

CONDITIONS<br />

FROST SUSCEPTIBILITY

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

INITIAL<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

LOW TRAFFIC EXAMPLE

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

INITIAL<br />

TERMINAL<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

IS THIS A CANDIDATE FOR FOAMED ASPHALT?<br />

FWD<br />

LOW TRAFFIC EXAMPLE

FLEXIBLE PAVEMENT EMPIRICAL DESIGN METHODS<br />

AASHTO 93 IS COMMONLY USED AASHTO 2002 COMING SOON<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

• MATERIALS<br />

GRANULAR SUBBASE<br />

GRANULAR BASE<br />

FOAMED ASPHALT<br />

ASPHALT CONCRETE<br />

GBE<br />

AASHTO 93 a i<br />

ASPHALT PAVEMENTS<br />

SN = a 1 D 1 + a 2 D 2 m 2 + a 3 D 3 m 3

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• MATERIALS<br />

GRANULAR SUBBASE<br />

GRANULAR BASE<br />

FOAMED ASPHALT<br />

ASPHALT CONCRETE<br />

GBE<br />

AASHTO 93 α i<br />

AASHTO 93 GRANULAR SUBBASE LAYER COEFFICIENT

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT LAYERS THICKNESS DESIGN<br />

AASHTO 93<br />

SN = a 1 D 1 + a 2 D 2 m 2 + a 3 D 3 m 3<br />

WHERE<br />

SN<br />

a 1 , a 2 , a 3<br />

D 1 , D 2 , D 3<br />

m 2 , m 3<br />

=<br />

=<br />

=<br />

=<br />

DESIGN STRUCTURAL NUMBER<br />

LAYER COEFFICIENTS REPRESENTATIVE<br />

OF SURFACE (INCLUDING FOAMED<br />

ASPHALT) BASE, AND SUBBASE<br />

COURSES, RESPECTIVELY<br />

ACTUAL THICKNESS OF SURFACE<br />

(INCLUDING FOAMED ASPHALT), BASE,<br />

AND SUBBASE COURSES, RESPECTIVELY<br />

DRAINAGE COEFFICIENTS FOR BASE<br />

AND SUBBASE COURSES, RESPECTIVELY<br />

CHECK FOR FATIGUE<br />

DESIGN STRUCTURAL NUMBER

FLEXIBLE PAVEMENT DESIGN<br />

WHY AASHTO 93?<br />

AASHTO 93<br />

• STRONG EMPIRICAL BACKGROUND<br />

AASHO ROAD TEST 1960s<br />

• WIDELY RECOGNIZED<br />

• EVOLVING INTO AASHTO 2002<br />

• DARWIN TM

FLEXIBLE PAVEMENT DESIGN<br />

DARWIN IS A PAVEMENT DESIGN SOFTWARE<br />

PROGRAM BASED ON “AASHTO GUIDE FOR THE<br />

DESIGN OF PAVEMENT STRUCTURES, 1993”.

FLEXIBLE PAVEMENT DESIGN<br />

LANE DISTRIBUTION FACTOR<br />

AASHTO 93<br />

NUMBER OF LANES<br />

IN EACH DIRECTION<br />

PERCENT OF 18-kip<br />

ESAL IN DESIGN<br />

LANE<br />

1 100<br />

2 80 – 100<br />

3 60 – 80<br />

4 50 - 75

FLEXIBLE PAVEMENT DESIGN<br />

LEVELS OF RELIABILITY<br />

AASHTO 93<br />

FUNCTIONAL<br />

CLASIFICATION<br />

INTERSTATE<br />

AND OTHER<br />

FREEWAYS<br />

PRINCIPAL<br />

ARTERIALS<br />

LEVEL OF RELIABILITY<br />

URBAN RURAL<br />

85 – 99.9 80 – 99.9<br />

80 – 99 75 – 95<br />

COLLECTORS 80 – 95 75 – 95<br />

LOCAL 50 - 80 50 - 80

FLEXIBLE PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

AASHTO 93 DRAINAGE COEFFICIENTS<br />

FOR FLEXIBLE PAVEMENTS

FLEXIBLE PAVEMENT DESIGN<br />

CHECK FOR FATIGUE<br />

AASHTO 93<br />

SHELL

RMRC RESEARCH

FLEXIBLE PAVEMENT EMPIRICAL DESIGN METHODS<br />

~ GRANULAR BASE EQUIVALENCY (GBE) FACTORS<br />

ONTARIO EXPERIENCE<br />

• NEW PROJECTS<br />

• HOT-MIX ASPHALT (INCLUDING RECYCLED) 2.0<br />

• GRANULAR BASE (CRUSHED, CBR ≥ 60) 1.0<br />

• GRANULAR SUBBASE (CBR < 60) 0.67<br />

• OGDL (NOT RECOMMENDED) 1.0<br />

• RESURFACING PROJECTS<br />

• OLD HOT-MIX ASPHALT 1.25<br />

• OLD GRANULAR BASE 0.75<br />

• OLD GRANULAR SUBBASE 0.50<br />

• RECONSTRUCTION PROJECTS<br />

• OLD HOT-MIX ASPHALT 1.0<br />

• OLD GRANULAR BASE 0.6<br />

• OLD GRANULAR SUBBASE 0.4<br />

• PULVERIZED RAP/GRANULAR BLEND 1.00<br />

• CIP 1.80<br />

• FOAMED/EXPANDED ASPHALT 1.80<br />

• RUBBLIZED BASE CONCRETE 1.0+

FLEXIBLE PAVEMENT DESIGN<br />

MTO GBE STRUCTURAL DESIGN GUIDELINES FOR FLEXIBLE<br />

PAVEMENTS - SECONDARY HIGHWAYS

FLEXIBLE PAVEMENT DESIGN<br />

LOW TRAFFIC ROAD EXAMPLE<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

• MATERIALS<br />

AASHTO 93

FLEXIBLE PAVEMENT DESIGN<br />

DARWIN BASED ON AASHTO 93<br />

EXAMPLE LOW VOLUME

FLEXIBLE PAVEMENT DESIGN<br />

AASHTO 93 DARWIN

FLEXIBLE PAVEMENT DESIGN<br />

CHECK FOR FATIGUE<br />

AASHTO 93 SHELL BISAR EXAMPLE COMPLETED

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

DEFLECTION OF PAVEMENT SECTION<br />

IN ADDITION TO THE SEASONAL VARIATIONS, THE DEFLECTION OF A PAVEMENT<br />

SECTION MAY VARY ALONG ITS LENGTH. TO REDUCE THE EFFECT OF BOTH<br />

VARIABLES, A STATISTICAL PROCESS IS USED WHEN ESTIMATING THE MAXIMUM<br />

DEFLECTION.<br />

• DIVIDE THE PAVEMENT INTO SECTIONS WHICH ARE 300M LONG. THE SECTIONS CAN BE<br />

OF VARIABLE LENGTH PROVIDED THEY ARE HOMOGENEOUS WITH RESPECT TO THE<br />

FACTORS WHICH INFLUENCE THE PAVEMENT DESIGN (E.G., SUBGRADE AND TRAFFIC)<br />

• SELECT AT LEAST 10 STRATIFIED TEST POINTS WITHIN EACH SECTION USING A TABLE<br />

OF RANDOM NUMBERS<br />

• OBTAIN THE DEFLECTION MEASUREMENT AT THE SELECTED TEST POINTS USING THE<br />

FALLING WEIGHT DEFLECTOMETER<br />

• CALCULATE THE AVERAGE DEFLECTION (X) AND THE STANDARD DEVIATION (σ x<br />

)<br />

• CALCULATE THE ESTIMATED MAXIMUM PROBABLE DEFLECTION VALUE<br />

D max = ( X + 2σ x )<br />

WATCH FOR OUTLIERS (LOCAL REPAIR), ADJUST FOR SEASON, SPRING ~ 1.5 x FALL,<br />

CONVERT TO STATIC (BENKELMAN BEAM EQUIVALENT), BENKELMAN BEAM ~ 1.5 X FWD

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

FWD<br />

• DEFLECTION<br />

• LAYER MODULI<br />

GRAPHICAL REPRESENTATION OF TYPICAL FWD DEFLECTION BASIN

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

MTO<br />

ONTARIO PAVEMENT OVERLAY DESIGN CRITERIA<br />

PAVEMENT THICKNESS/DEFLECTION RELATIONSHIP<br />

ASPHALT<br />

INSTITUTE<br />

HAS<br />

SIMILAR<br />

APPROACH

TESTING OF FOAMED ASPHALT AND HMA<br />

PERFORMANCE AND CHARACTERIZATION TESTING<br />

APA<br />

ASPHALT<br />

PAVEMENT<br />

ANALYZER<br />

(PTI)<br />

APA<br />

DESIGN<br />

LABORATORY<br />

PROOF<br />

TESTER<br />

ASPHALT<br />

PLANT<br />

PLACEMENT<br />

LINK BETWEEN LABORATORY TESTING<br />

AND FIELD PERFORMANCE<br />

NAT<br />

RESILIENT MODULUS<br />

PERMANENT DEFORMATION<br />

FATIGUE ENDURANCE<br />

FOR RESILIENT MODULUS OF SUBGRADES AND GRANULAR MATERIALS<br />

JEGEL USES FWD, DCP AND LABORATORY SOIL DYNAMICS TESTING<br />

ASPHALT PAVEMENT ANALYZER AND NOTTINGHAM ASPHALT TESTER IN JEGEL LABORATORY

TECHNICAL LITERATURE INDICATES THE STRUCTURAL<br />

COEFFICIENTS FOR FOAMED ASPHALT ARE GENERALLY<br />

SIMILAR TO THOSE FOR CIR FOR PROPERLY DESIGNED<br />

AND CONSTRUCTED FOAMED ASPHALT STABILIZATION<br />

(QUALITY VERY IMPORTANT)<br />

MTO HIGHWAY 3 CIR COMPLETED IN 1992<br />

1.4 PERCENT HF 150P, CONDITION IN 1997

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

CORES FROM MTO HIGHWAY 3<br />

THE CIR BASE HAS THE APPEARANCE OF HMA

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

MECHANISTIC DESIGN MODULI<br />

GRANULAR BASE EQUIVALENCY (GBE)<br />

• NOTTINGHAM ASPHALT TESTER (NAT)<br />

– RESILIENT PROPERTIES<br />

– LABORATORY AND FIELD SAMPLES<br />

• REPRESENTATIVE FIELD SAMPLES TESTED<br />

– PROJECTS COMPLETED FROM 1991 TO 1996<br />

• MECHANISTIC DESIGN SUBGRADE STRAINS<br />

(BISAR)<br />

• GBE OF ~ 1.8 (a 1 ~ 0.35 - 0.40) NOTE – GBE AND a 1 ARE FOR<br />

PROPERLY DESIGNED AND CONSTRUCTED FOAMED<br />

ASPHALT STABILIZATION (QUALITY VERY IMPORTANT)

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

GRANULAR BASE EQUIVALENCY (GBE) FACTOR INCREASE WITH AGE<br />

OF COLD IN-PLACE RECYCLED ASPHALT

FOAMED ASPHALT STABILIZATION<br />

CHARACTERIZATION IN JEGEL NAT<br />

• RESILIENT MODULUS<br />

• PERMANENT DEFORMATION (RUTTING)<br />

• FATIGUE ENDURANCE

CHARACTERIZATION OF HMA AND FDR (FOAMED ASPHALT) CORES<br />

FROM TYPICAL GEORGIA PROJECTS – BLOUNT CONSTRUCTION<br />

LOCATION AND DEPTH OF CORES SUPPLIED BY CONTRACTOR<br />

GEORGIA<br />

LOCATION<br />

HOUZE WAY<br />

CORE<br />

ID.<br />

AVERAGE LAYER<br />

DEPTH<br />

HMA FOAMED<br />

(mm) ASPHALT<br />

(mm)<br />

DESCRIPTION<br />

H-1 44 125 CENTERLINE EB TURNING LANE INTO FUDDRUCKERS<br />

H-2 35 132 CENTERLINE WB TURNING LANE INTO ROSWELL BICYCLE PATH<br />

H-3 32 118 CENTERLINE WB TURNING LANE INTO 600 HOUZE WAY<br />

TRAMMEL<br />

ROAD<br />

JOTTEM DOWN<br />

ROAD<br />

MCGINNIS<br />

FERRY ROAD<br />

T-1 32 189 CENTERLINE LEFT SIDE, APPROX. 150M FROM PROJECT END<br />

T-2 38 159 CENTERLINE RIGHT SIDE, IN FRONT OF MAIL BOX 3711<br />

T-3 25 150 CENTERLINE LEFT SIDE, IN FRONT OF MAIL BOX 378<br />

J-1 49 156 CENTERLINE OF LANE, IN FRONT OF MAIL BOX 8700<br />

J-2 41 151 CENTERLINE OF LANE, ACROSS FROM MAIL BOX 9030<br />

J-3 50 152 CENTERLINE OF LANE, IN FRONT OF MAIL BOX 7865<br />

M-1 35 120 CENTER TURNING LANE AT WINDWARD RIDGE<br />

M-2 32 152 CENTER TURNING LANE AT JOHN DEERE LANDSCAPE<br />

M-3 25 165 CENTER TURNING LANE AT BROOKWOOD SUBWAY<br />

NOTE: 1. THREE CORES WERE SUPPLIED BY THE CONTRACTOR AT EACH LOCATION DESCRIBED ABOVE.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF FOAMED ASPHALT MIX DESIGN PROPORTIONS<br />

AT VARIOUS PROJECT LOCATIONS<br />

GEORGIA<br />

LOCATION<br />

ASPHALT<br />

MATERIAL<br />

(%)<br />

EXISTING<br />

GRANULAR<br />

(%)<br />

MATERIAL<br />

ASPHALT<br />

CEMENT<br />

(67-22)<br />

(%)<br />

HYDRATED<br />

LIME<br />

ADDITION<br />

(%)<br />

ASPHALT<br />

MATERIAL<br />

(%)<br />

EXISTING<br />

GRANULAR<br />

(%)<br />

MIX<br />

ASPHALT<br />

CEMENT<br />

(67-22)<br />

(%)<br />

HYDRATED<br />

LIME<br />

ADDITION<br />

(%)<br />

TOTAL TOTAL<br />

ASPHALT MOISTURE<br />

CEMENT CONTENT<br />

CONTENT (%) [2]<br />

(%) [1]<br />

HOUZE WAY<br />

(SECTION A)<br />

HOUZE WAY<br />

(SECTION B)<br />

TRAMMEL<br />

ROAD<br />

JOTTEM<br />

DOWN ROAD<br />

MCGINNIS<br />

FERRY ROAD<br />

85.0 15.0 - - 83.1 14.7 2.2 - 6.73 6.3<br />

49.5 49.5 - 1.0 48.2 48.2 2.6 1.0 5.22 5.9<br />

75.0 25.0 - - 73.1 24.4 2.5 - 7.14 6.0<br />

74.5 24.5 - 1.0 73.0 24.0 2.0 1.0 6.72 6.5<br />

- - - - - - - - - -<br />

NOTES: 1. INCLUDING RESIDUAL PLUS ADDED.<br />

2. INCLUDING IN-SITU PLUS ADDED.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

FOAMED ASPHALT MIX DESIGN DATA VS. LABORATORY TESTING RESULTS<br />

AT VARIOUS PROJECT LOCATIONS<br />

GEORGIA<br />

SIEVE<br />

SIZE<br />

PERCENT<br />

PASSING<br />

Section<br />

A,<br />

JMF<br />

HOUZE WAY TRAMMELL ROAD JOTTON DOWN<br />

ROAD<br />

Section Top Lower JMF Top Lower JMF Top Lower<br />

B, FDR FDR<br />

FDR FDR<br />

FDR FDR<br />

JMF Layer Layer Layer Layer Layer Layer<br />

MCGINNIS FERRY<br />

ROAD<br />

JMF Top Lower<br />

FDR FDR<br />

Layer Layer<br />

50.0 mm 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

37.5 mm 100.0 95.8 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

26.5 mm 98.9 91.7 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

19.0 mm 97.7 82.6 98.6 98.3 97.6 100.0 100.0 97.0 94.7 100.0 - 98.6 98.9<br />

16.0 mm 94.7 77.1 98.2 97.1 94.5 96.9 99.1 94.2 92.2 99.0 - 97.9 98.9<br />

13.2 mm 89.2 73.3 95.7 95.0 91.8 96.0 99.1 92.3 90.2 97.2 - 97.7 98.5<br />

9.5 mm 81.8 68.1 88.8 91.4 86.7 94.1 96.9 89.5 87.6 94.7 - 96.5 95.1<br />

4.75 mm 62.4 49.8 73.4 76.4 60.8 76.4 82.0 72.8 74.9 84.5 - 81.4 77.9<br />

2.36 mm 46.8 39.5 57.4 60.1 43.1 58.2 62.5 61.5 63.5 72.9 - 62.5 60.6<br />

1.18 mm 38.3 34.4 47.1 49.0 34.5 45.7 50.9 54.0 53.9 62.7 - 51.4 49.1<br />

600 µm 31.9 30.6 38.8 40.1 28.6 35.9 43.4 48.3 44.2 51.6 - 44.1 39.5<br />

300 µm 25.3 25.6 30.4 31.1 22.5 26.9 35.8 35.5 32.2 37.3 - 36.4 30.3<br />

150 µm 18.9 19.6 21.2 21.6 15.6 17.2 25.1 24.2 19.4 21.9 - 25.2 19.8<br />

75 µm 13.9 14.4 13.3 14.3 9.9 9.7 15.7 15.5 10.9 12.6 - 15.0 12.0<br />

ASPHALT CEMENT<br />

CONTENT 6.73 5.22 5.83 5.59 7.14 5.97 6.27 6.72 6.03 3.89 - 6.43 5.36<br />

Percent by Mass<br />

AIR VOIDS (%) 8.2 10.1 11.8 14.9 9.8 14.1 14.9 8.9 19.4 24.8 - 15.8 19.4<br />

BRD 2.118 2.100 2.197 2.127 2.198 2.065 2.044 2.091 1.974 1.907 - 2.018 1.956

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF AVERAGE BRD, MRD, AIR VOIDS AND RESILIENT MODULUS<br />

OF ASPHALT CONCRETE SURFACE COURSE, TOP FOAMED ASPHALT<br />

COURSE AND BOTTOM FOAMED ASPHALT COURSE SAMPLES<br />

GEORGIA<br />

SAMPLE<br />

HMA<br />

TOP<br />

FOAMED<br />

ASPHALT<br />

LOWER<br />

FOAMED<br />

ASPHALT<br />

SAMPLE<br />

LOCATION<br />

AVERAGE<br />

BULK<br />

RELATIVE<br />

DENSITY<br />

(BRD)<br />

COMPOSITE<br />

MAXIMUM<br />

RELATIVE<br />

DENSITY<br />

(MRD)<br />

AVERAGE<br />

AIR<br />

VOIDS<br />

(%)<br />

AVERAGE<br />

RESILIENT<br />

MODULUS<br />

@ 20°C<br />

(MPa)<br />

AVERAGE<br />

RESILIENT<br />

MODULUS<br />

AFTER<br />

CONDITIONING<br />

@ 20°C<br />

(MPa) [2]<br />

HOUZE WAY 2.363 2.538 6.9 7957 -<br />

TRAMMEL ROAD 2.303 2.498 7.8 9031 -<br />

JOTTEM DOWN ROAD 2.380 2.492 4.5 7668 -<br />

MCGINNIS FERRY ROAD 2.296 2.535 9.4 4442 -<br />

HOUZE WAY 2.197 2.491 11.8 4804 -<br />

TRAMMEL ROAD 2.065 2.405 14.1 2398 -<br />

JOTTEM DOWN ROAD 1.974 2.450 19.4 2989 -<br />

MCGINNIS FERRY ROAD 2.018 2.396 15.8 3337 -<br />

HOUZE WAY 2.127 2.499 14.9 2540 -<br />

TRAMMEL ROAD 2.044 2.403 14.9 2492 1564<br />

JOTTEM DOWN ROAD 1.907 2.535 24.8 1829 1199<br />

MCGINNIS FERRY ROAD 1.956 2.424 19.4 2566 1786<br />

NOTES: 1. ALL AVERAGE VALUES WERE OBTAINED BASED ON THE TEST OF THREE SAMPLES<br />

EXCLUDING OUTLIERS.<br />

2. LOWER LAYER FOAMED ASPHALT SAMPLES WERE IMMERSED IN WATER FOR 24 HOURS AT<br />

TEMPERATURE RANGED BETWEEN 20 TO 25°C, THEN DRAINED AND DRIED UNDER<br />

LABORATORY AMBIENT AIR FOR 1 HOUR PRIOR TO TESTING.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF RESILIENT MODULUS TESTING RESULTS<br />

HOT MIX ASPHALT AND FOAMED ASPHALT MIX<br />

HOUZE WAY, CITY OF ROSWELL, GEORGIA<br />

LAYER<br />

TYPE<br />

AVERAGE RESILIENT MODULUS (MPa)<br />

10°C 25°C 35°C 20°C<br />

HMA 11809 5236 2115 7957<br />

TOP FOAMED ASPHALT 6582 4947 3087 5319<br />

LOWER FOAMED ASPHALT 5831 4536 2566 4457<br />

BOTTOM FOAMED ASPHALT 1970 1639 994 2540<br />

NOTES: 1. ALL RESILIENT MODULUS VALUES WERE OBTAINED BASED ON THE TEST OF THREE<br />

SAMPLES EXCLUDING OUTLIERS.<br />

2. TESTING RESULTS AT 20°C WERE CONDUCTED USING A DIFFERENT SET OF SAMPLE<br />

SPECIMENS FROM THE SAME CORING LOCATION AS THE REST OF THE TESTING<br />

SPECIMENS.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

RESILIENT MODULUS (MPa)<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

RESILIENT MODULUS VS. TEMPERATURE RELATIONSHIP<br />

HOT MIX ASPHALT AND EXPANDED ASPHALT MIX<br />

(HOUZE WAY, CITY OF ROSWELL, GEORGIA)<br />

HMA<br />

TOP FOAMED ASPHALT<br />

LOWER FOAMED ASPHALT<br />

BOTTOM FOAMED ASPHALT<br />

HMA AT 20°C<br />

TOP FOAMED ASPHALT AT 20°C<br />

MIDDLE FOAMED ASPHALT AT 20°C<br />

LOWER FOAMED ASPHALT AT 20°C<br />

TYPICAL RANGE OF RESILIENT MODULUS<br />

FOR DENSE-GRADED ASPHALT MIXTURES<br />

4000<br />

2000<br />

0<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE (°C)

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

LTPP DESIGN SUMMER PAVEMENT TEMPERATURES ( O C)<br />

98% RELIABILITY<br />

CITY<br />

DEPTH (mm)<br />

0 50 100 150<br />

ATLANTA, GEORGIA 60.1 55.2 52.4 50.5<br />

DETROIT, MICHIGAN 56.4 51.5 48.7 46.8<br />

KANSAS CITY, MISSOURI 60.6 55.7 52.9 50.9<br />

TORONTO, ONTARIO 54.9 50 47.2 45.2

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

RESILIENT MODULUS (MPa)<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

RESILIENT MODULUS VS. TEMPERATURE RELATIONSHIP<br />

HOT MIX ASPHALT AND EXPANDED ASPHALT MIX<br />

(HOUZE WAY, CITY OF ROSWELL, GEORGIA)<br />

HMA<br />

TOP FOAMED ASPHALT<br />

LOWER FOAMED ASPHALT<br />

BOTTOM FOAMED ASPHALT<br />

HMA AT 20°C<br />

TOP FOAMED ASPHALT AT 20°C<br />

MIDDLE FOAMED ASPHALT AT 20°C<br />

LOWER FOAMED ASPHALT AT 20°C<br />

TYPICAL RANGE OF RESILIENT MODULUS<br />

FOR DENSE-GRADED ASPHALT MIXTURES<br />

4000<br />

2000<br />

0<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE (°C)

FOAMED ASPHALT STABILIZATION CHARACTERIZATION IN JEGEL NAT<br />

0.7<br />

AASHTO 93 a 1 STRUCTURAL LAYER COEFFICIENT<br />

FOR HOT-MIX ASPHALT AND FOAMED ASPHALT<br />

0.65<br />

STRUCTURAL LAYER COEFFICIENT a 1<br />

0.6<br />

0.55<br />

0.5<br />

0.45<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

HMA<br />

UPPER FOAMED<br />

ASPHALT<br />

LOWER FOAMED<br />

ASPHALT<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE ( o C)<br />

a 1 DETERMINED FROM<br />

a<br />

⎡ E ⎤<br />

0.40Log<br />

⎢ 450⎥<br />

⎣ ⎦<br />

RT<br />

1<br />

= +<br />

0.44<br />

a 1 IS DOTTED WHEN GREATER THAN 0.5<br />

AS GIVEN IN FHWA-RD-97-077

FOAMED ASPHALT STABILIZATION CHARACTERIZATION IN JEGEL NAT<br />

2.45<br />

GRANULAR BASE EQUIVALENCY FOR HOT-MIX ASPHALT<br />

AND FOAMED ASPHALT BASED ON MTO (GBE OF HMA = 2)<br />

GRANULAR BASE EQUIVALENCY<br />

2.25<br />

2.05<br />

1.85<br />

1.65<br />

1.45<br />

HMA<br />

UPPER FOAMED<br />

ASPHALT<br />

LOWER<br />

FOAMED<br />

ASPHALT<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE ( o C)<br />

GRANULAR BASE EQUIVALENCY (GBE) OF HOT-MIX ASPHALT<br />

TAKEN AS 2 BASED ON MTO<br />

GBE IS DOTTED WHEN GREATER THAN 2.0

LIFE-CYCLE COST ANALYSIS<br />

“WE GO OUT AND BUY PAVEMENTS LIKE WE WOULD ZUCCHINI.<br />

ALL WE CARE ABOUT IS PRICE.”<br />

DAMIAN J. KULASH, EXECUTIVE DIRECTOR, STRATEGIC<br />

HIGHWAY RESEARCH PROGRAM, 1993

LIFE-CYCLE COST ANALYSIS<br />

• ECONOMIC ASSESSMENT OF COMPETING, TECHNICALLY<br />

SUITABLE SYSTEMS OVER DESIGN LIFE<br />

• COST COMPONENTS<br />

INITIAL COSTS (CAPITAL COSTS)<br />

MAINTENANCE COSTS<br />

REHABILITATION COSTS<br />

RESIDUAL/SALVAGE VALUES<br />

USER COSTS (TRAFFIC DELAY FOR INSTANCE)<br />

• PRESENT WORTH METHOD<br />

ANALYSIS PERIOD (TYPICALLY 30 TO 40 YEARS – AT LEAST ONE<br />

REHABILITATION)<br />

DISCOUNT RATE (TYPICALLY ABOUT 4 PERCENT)<br />

PRESENT WORTH (REMEMBER RULE OF 72)<br />

• FOAMED ASPHALT WITH HMA OVERLAY LIFE-CYCLE COST<br />

ANALYSES GENERALLY VERY FAVOURABLE COMPARED TO<br />

PULVERIZE/'THICKER ' HMA OR MILL/RECYCLED HMA/HMA

LIFE-CYCLE COST ANALYSIS<br />

INITIAL COSTS<br />

LARGELY DETERMINE THE LIFE-CYCLE COST<br />

FOR 20 YEAR PAVEMENT DESIGNS<br />

TYPICAL ONTARIO FDR PROJECT

LIFE-CYCLE COST ANALYSIS<br />

MAINTENANCE COST EFFECTIVENESS<br />

ASSET MANAGEMENT

EXAMPLE OF FOAMED ASPHALT OR CIR<br />

LIFE-CYCLE COST ANALYSIS<br />

• INTEREST RATE 8 PERCENT, INFLATION RATE 4 PERCENT<br />

- DISCOUNT RATE 3.85 PERCENT<br />

• ALTERNATIVES BASED ON EQUIVALENT GRANULAR BASE<br />

EQUIVALENCIES (GBE)<br />

- EXISTING PAVEMENT 100 mm ASPHALT CONCRETE<br />

150 mm GRANULAR BASE<br />

GRANULAR SUBBASE<br />

SUBGRADE<br />

• GBE OF 1.8 USED FOR FOAMED ASPHALT AND CIR<br />

• INITIAL COST OF PAVEMENT STRUCTURE ONLY<br />

- AVERAGE MTO 1996 UNIT PRICES<br />

• MAINTENANCE AND REHABILITATION SCHEDULE BASED ON<br />

JEGEL EXPERIENCE

FLEXIBLE PAVEMENT DESIGN<br />

LIFE-CYCLE COST ANALYSIS<br />

PULVERIZE 200 mm<br />

40 mm HL 8<br />

50 mm OF HL 3<br />

EXAMPLE<br />

FOAMED COLD IN-PLACE ASPHALT<br />

OR RECYCLE CIR 100 mm<br />

50 mm OF HL 3<br />

MILL 40 mm<br />

65 mm OF RECYCLED HL 8<br />

50 mm OF HL 3<br />

INITIAL COST 29,526 31,275 35,700<br />

PRESENT<br />

WORTH OF<br />

MAINT. COSTS<br />

PRESENT<br />

WORTH OF<br />

REHAB. COSTS<br />

PRESENT<br />

WORTH OF<br />

RESIDUAL<br />

COSTS<br />

TOTAL<br />

PRESENT<br />

WORTH OF<br />

COSTS<br />

12,322 13,715 12,332<br />

22,478 8,706 22,478<br />

(10,178) (2,175) (10,277)<br />

54,158 51,521 60,233<br />

RANK 2 1 3

EXAMPLE OF VALUE ENGINEEING<br />

SUPERPAVE PLUS<br />

FOAMED ASPHALT OR CIR AND<br />

SUPERPAVE OVERLAY

AASHTO 2002<br />

AT EARLY IMPLEMENTATION STAGE<br />

GENERAL DESIGN APPROACH<br />

ENVIRONMENT<br />

MATERIALS<br />

<br />

TRAFFIC<br />

PROCESS RAW INPUT FOR DISTRESS MODELING<br />

<br />

ASSEMBLE INPUT AND TRIAL DESIGN<br />

INFORMATION FOR EACH DISTRESS MODEL<br />

<br />

STRESS DEFLECTION ANALYSIS<br />

CALCULATE STRESS ∪ CALCULATE DAMAGE ∪ PREDICT AMOUNT OF DISTRESS<br />

<br />

PREDICT SMOOTHNESS OVER TIME<br />

<br />

CHECK PREDICTED PERFORMANCE<br />

AGAINST DESIGN STANDARDS<br />

<br />

[ REVISE DESIGN AS NECESSARY ]<br />

TO SATISFY DESIGN STANDARD<br />

<br />

DESIGN COMPLETE

QUESTIONS ?<br />

PLEASE CONTACT JOHN EMERY AT JEGEL WITH YOUR QUESTIONS<br />

416-213-1060 jemery@jegel.com www.jegel.com