Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

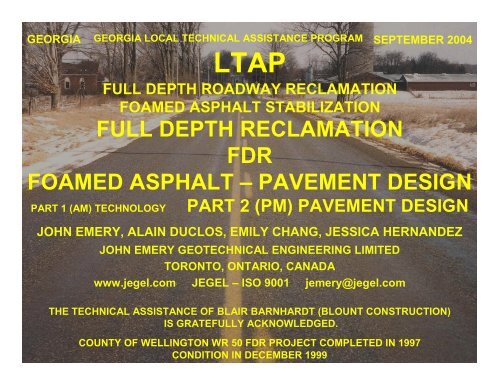

GEORGIA GEORGIA LOCAL TECHNICAL ASSISTANCE PROGRAM SEPTEMBER 2004<br />

LTAP<br />

FULL DEPTH RECLAMATION<br />

FDR<br />

FOAMED ASPHALT – PAVEMENT DESIGN<br />

PART 1 (AM) TECHNOLOGY<br />

FULL DEPTH ROADWAY RECLAMATION<br />

FOAMED ASPHALT STABILIZATION<br />

PART 2 (PM) PAVEMENT DESIGN<br />

JOHN EMERY, ALAIN DUCLOS, EMILY CHANG, JESSICA HERNANDEZ<br />

JOHN EMERY GEOTECHNICAL ENGINEERING LIMITED<br />

TORONTO, ONTARIO, CANADA<br />

www.jegel.com JEGEL – ISO 9001 jemery@jegel.com<br />

THE TECHNICAL ASSISTANCE OF BLAIR BARNHARDT (BLOUNT CONSTRUCTION)<br />

IS GRATEFULLY ACKNOWLEDGED.<br />

COUNTY OF WELLINGTON WR 50 FDR PROJECT COMPLETED IN 1997<br />

CONDITION IN DECEMBER 1999

FOAMED ASPHALT PART 1 CONCLUSIONS<br />

• ADVANTAGES<br />

– EASY APPLICATION<br />

– FLEXIBLE LAYER WITH GOOD RUTTING AND FATIGUE PROPERTIES<br />

– ECONOMIC (LCCA)<br />

– RAPID STRENGTH GAIN - ROAD CAN BE OPENED AFTER COMPACTION<br />

– REFLECTIVE CRACKING MITIGATION<br />

• DISADVANTAGES<br />

– REQUIRES A SUPPLY OF HOT (~160°C, 320°F PLUS) ASPHALT CEMENT<br />

– STABILIZED MATERIAL SHOULD HAVE 5 TO 15 PERCENT PASSING 75 µm<br />

• FOAMED (EXPANDED) ASPHALT STABILIZATION WELL ESTABLISHED, PROVEN<br />

AND COST EFFECTIVE<br />

• REFLECTIVE CRACKING MITIGATION<br />

• PROFILE CORRECTION AND SUPERELEVATION RESTORATION<br />

• RECOMMEND AGENCY EVALUATE PAVEMENT/SET PERFORMANCE<br />

SPECIFICATIONS AND ACCEPTANCE (QA)<br />

• RECOMMEND CONTRACTOR RESPONSIBLE FOR DESIGN/PROCESS/MATERIALS<br />

PERFORMANCE AND QUALITY CONTROL<br />

• RECOMMEND STABILIZATION PROCESS BE SEPARATE PAY ITEM<br />

• a 1 OF ~ 0.35 TO 0.40 FOR AASHTO SN (GBE OF ~ 1.8) FOR PROPERLY DESIGNED<br />

AND CONSTRUCTED FOAMED ASPHALT STABILIZATION (QUALITY VERY<br />

IMPORTANT)

FLEXIBLE PAVEMENT DESIGN<br />

THE QUALITY OF WORK PERFORMED<br />

DIRECTLY INFLUENCES THE USEFUL LIFE OF<br />

THE PAVEMENT, MAINTENANCE COSTS, LEVEL<br />

OF SERVICE AND USER COSTS<br />

CHALLENGING TIME FOR PAVEMENTS<br />

• INCREASING TRAFFIC VOLUMES AND TRUCK LOADINGS<br />

• LIMITED CAPITAL AND MAINTENANCE FUNDS<br />

• NETWORKS IN NEED OF MAINTENANCE AND IMPROVEMENT<br />

• MANY BRIDGES ARE DEFICIENT<br />

DON VALLEY PARKWAY IN TORONTO<br />

LONG-LIFE ASPHALT PAVEMENT – PERPETUAL PAVEMENT

PART 2<br />

F<br />

E<br />

E<br />

D<br />

B<br />

A<br />

C<br />

K<br />

INVENTORY<br />

INVENTORY<br />

FLEXIBLE PAVEMENT DESIGN<br />

INPUT<br />

INPUT<br />

INFORMATION<br />

INFORMATION<br />

PERFORMANCE<br />

PERFORMANCE<br />

CRITERIA<br />

CRITERIA<br />

PAVEMENT<br />

PAVEMENT<br />

MODELS<br />

MODELS<br />

PAVEMENT<br />

PAVEMENT<br />

SERVICEABILITY<br />

SERVICEABILITY<br />

PAVEMENT<br />

PAVEMENT<br />

MATERIALS<br />

MATERIALS<br />

PAVEMENT<br />

PAVEMENT<br />

DESIGN<br />

DESIGN<br />

NEW,<br />

NEW,<br />

OVERLAY,<br />

OVERLAY,<br />

REHABILITATION<br />

REHABILITATION<br />

CONSTRUCT<br />

CONSTRUCT<br />

PAVEMENT<br />

PAVEMENT<br />

OR<br />

OR<br />

OVERLAY<br />

OVERLAY<br />

PAVEMENT<br />

PAVEMENT<br />

OR<br />

OR<br />

REHABILITATE<br />

REHABILITATE<br />

PAVEMENT<br />

PAVEMENT<br />

SYSTEMATIC<br />

SYSTEMATIC<br />

PAVEMENT<br />

PAVEMENT<br />

MAINTENANCE<br />

MAINTENANCE<br />

MAINTENANCE<br />

MAINTENANCE<br />

MANAGEMENT<br />

MANAGEMENT<br />

SYSTEM<br />

SYSTEM<br />

PAVEMENT<br />

PAVEMENT<br />

MANAGEMENT<br />

MANAGEMENT<br />

SYSTEM<br />

SYSTEM<br />

PERFORMANCE<br />

PERFORMANCE<br />

MONITORING<br />

MONITORING<br />

SAFE,<br />

SAFE,<br />

SMOOTH,<br />

SMOOTH,<br />

SURFACES<br />

SURFACES<br />

HAPPY<br />

HAPPY<br />

CUSTOMERS<br />

CUSTOMERS<br />

LIFE-CYCLE COST ANALYSIS AND VALUE ENGINEERING<br />

• TRAFFIC (ESALs)<br />

•SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• BUDGET<br />

• RUTTING<br />

•FATIGUE<br />

• THERMAL<br />

•INITIAL<br />

•TERMINAL<br />

• PCI - PSR<br />

•IRI<br />

• SUBBASE<br />

• BASE<br />

• ASPHALT CONCRETE<br />

SUPERPAVE<br />

PGAC, VOLUMETRIC, PERFORMANCE<br />

•GBE<br />

• AASHTO 93<br />

• COMING SOON - AASHTO 2002<br />

• LCCA AND VE<br />

•QC<br />

•QA<br />

• CRACK SEALING<br />

• SUMMER MAINTENANCE<br />

• WINTER MAINTENANCE<br />

• PAVEMENT PRESERVATION<br />

• INVENTORY (DATA BANK)<br />

• MONITOR PERFORMANCE<br />

• NETWORK LEVEL<br />

• PROJECT LEVEL<br />

• BUDGET<br />

• WINTER SURFACE CONDITION<br />

• MOVING TO PMS/MMS/AMS<br />

•PERPETUAL FLEXIBLE PAVEMENTS

FLEXIBLE PAVEMENT DESIGN<br />

FLEXIBLE PAVEMENTS<br />

• STRONG<br />

• DURABLE<br />

• SMOOTH<br />

• SAFE<br />

• ECONOMIC<br />

HIGHWAY AND AIRPORT<br />

CITY OF TORONTO ROYAL YORK ROAD 1997 CIR PROJECT WITH HMA SURFACE<br />

CURRENT CONDITION

FLEXIBLE PAVEMENT DESIGN<br />

ASPHALT<br />

GRANLAR BASE OR FOAMED ASPHALT<br />

GRANULAR SUBBASE<br />

SUBGRADE<br />

TYPICAL PAVEMENT STRUCTURE

• PERFORMANCE CRITERIA<br />

– RUTTING AND FATIGUE<br />

• PAVEMENT DESIGN INPUT REQUIRED<br />

– TRAFFIC<br />

– SUBGRADE<br />

– DRAINAGE CONDITIONS<br />

- KEY TO PAVEMENT PERFORMANCE<br />

- DRAINAGE, DRAINAGE, DRAINAGE<br />

- TAKE THE WATER OUT, KEEP THE WATER OUT<br />

– ENVIRONMENTAL CONDITIONS<br />

– MATERIALS<br />

- GRANULAR MATERIALS<br />

- FOAMED ASPHALT<br />

- ASPHALT CONCRETE<br />

– SERVICEABILITY<br />

FLEXIBLE PAVEMENT DESIGN<br />

- INITIAL AND TERMINAL

FLEXIBLE PAVEMENT DESIGN<br />

• PERFORMANCE CRITERIA<br />

RUTTING<br />

TOTAL PAVEMENT - SUBGRADE, GRANULAR SUBBASE,<br />

GRANULAR BASE, FOAMED ASPHALT AND/OR ASPHALT<br />

CONCRETE<br />

FATIGUE<br />

ASPHALT CONCRETE AND FOAMED ASPHALT

FLEXIBLE PAVEMENT DESIGN<br />

CRITICAL STRAINS FOR MECHANISTIC ANALYSIS<br />

HORIZONTAL STRAIN AT BOTTOM<br />

OF ASPHALT CONCRETE<br />

OR FOAMED ASPHALT<br />

VERTICAL STRAIN AT TOP OF SUBGRADE

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

•TRAFFIC<br />

TYPE, MASS AND NUMBER (AADT)<br />

ESALs

• TRAFFIC<br />

• SUBGRADE<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

BOREHOLE INVESTIGATION<br />

CBR TESTING<br />

LABORATORY MR TESTING<br />

DYNAMIC CONE PENETROMETER TESTING<br />

FWD TESTING<br />

PARTICULARLY FOR REHABILITATION

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT EVALUATION<br />

• VISUAL CONDITION SURVEY<br />

• CORING/BOREHOLE INVESTIGATION TO DETERMINE THE<br />

THICKNESS OF THE ASPHALT CONCRETE PAVEMENT<br />

LAYER(S) AND GRANULAR BASE/SUBBASE AND TO OBTAIN<br />

SAMPLES FOR LABORATORY TESTING<br />

• FALLING WEIGHT DEFLECTOMETER (FWD) LOAD/DEFLECTION<br />

TESTING TO DETERMINE THE STRUCTURAL CAPACITY OF<br />

THE PAVEMENT<br />

• LABORATORY TESTING OF MATERIALS OBTAINED ON SITE<br />

• EMPIRICAL OR MECHANISTIC-EMPIRICAL PAVEMENT<br />

STRUCTURE ANALYSIS (DESIGN)<br />

IS THIS A SUITABLE SECTION FOR FOAMED ASPHALT<br />

•DRAINAGE?<br />

•STRUCTURAL ADEQUACY? FWD

• TRAFFIC<br />

• SUBGRADE<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• DRAINAGE CONDITIONS<br />

KEY TO PAVEMENT PERFORMANCE<br />

1. DRAINAGE<br />

2. DRAINAGE<br />

3. DRAINAGE<br />

TAKE THE WATER OUT. KEEP THE<br />

WATER OUT.

FLEXIBLE PAVEMENT DESIGN<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

IMPROVE OR INSTALL AS NECESSARY

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL<br />

CONDITIONS<br />

FROST SUSCEPTIBILITY

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

INITIAL<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

LOW TRAFFIC EXAMPLE

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

INITIAL<br />

TERMINAL<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

IS THIS A CANDIDATE FOR FOAMED ASPHALT?<br />

FWD<br />

LOW TRAFFIC EXAMPLE

FLEXIBLE PAVEMENT EMPIRICAL DESIGN METHODS<br />

AASHTO 93 IS COMMONLY USED AASHTO 2002 COMING SOON<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

• MATERIALS<br />

GRANULAR SUBBASE<br />

GRANULAR BASE<br />

FOAMED ASPHALT<br />

ASPHALT CONCRETE<br />

GBE<br />

AASHTO 93 a i<br />

ASPHALT PAVEMENTS<br />

SN = a 1 D 1 + a 2 D 2 m 2 + a 3 D 3 m 3

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

• MATERIALS<br />

GRANULAR SUBBASE<br />

GRANULAR BASE<br />

FOAMED ASPHALT<br />

ASPHALT CONCRETE<br />

GBE<br />

AASHTO 93 α i<br />

AASHTO 93 GRANULAR SUBBASE LAYER COEFFICIENT

FLEXIBLE PAVEMENT DESIGN<br />

PAVEMENT LAYERS THICKNESS DESIGN<br />

AASHTO 93<br />

SN = a 1 D 1 + a 2 D 2 m 2 + a 3 D 3 m 3<br />

WHERE<br />

SN<br />

a 1 , a 2 , a 3<br />

D 1 , D 2 , D 3<br />

m 2 , m 3<br />

=<br />

=<br />

=<br />

=<br />

DESIGN STRUCTURAL NUMBER<br />

LAYER COEFFICIENTS REPRESENTATIVE<br />

OF SURFACE (INCLUDING FOAMED<br />

ASPHALT) BASE, AND SUBBASE<br />

COURSES, RESPECTIVELY<br />

ACTUAL THICKNESS OF SURFACE<br />

(INCLUDING FOAMED ASPHALT), BASE,<br />

AND SUBBASE COURSES, RESPECTIVELY<br />

DRAINAGE COEFFICIENTS FOR BASE<br />

AND SUBBASE COURSES, RESPECTIVELY<br />

CHECK FOR FATIGUE<br />

DESIGN STRUCTURAL NUMBER

FLEXIBLE PAVEMENT DESIGN<br />

WHY AASHTO 93?<br />

AASHTO 93<br />

• STRONG EMPIRICAL BACKGROUND<br />

AASHO ROAD TEST 1960s<br />

• WIDELY RECOGNIZED<br />

• EVOLVING INTO AASHTO 2002<br />

• DARWIN TM

FLEXIBLE PAVEMENT DESIGN<br />

DARWIN IS A PAVEMENT DESIGN SOFTWARE<br />

PROGRAM BASED ON “AASHTO GUIDE FOR THE<br />

DESIGN OF PAVEMENT STRUCTURES, 1993”.

FLEXIBLE PAVEMENT DESIGN<br />

LANE DISTRIBUTION FACTOR<br />

AASHTO 93<br />

NUMBER OF LANES<br />

IN EACH DIRECTION<br />

PERCENT OF 18-kip<br />

ESAL IN DESIGN<br />

LANE<br />

1 100<br />

2 80 – 100<br />

3 60 – 80<br />

4 50 - 75

FLEXIBLE PAVEMENT DESIGN<br />

LEVELS OF RELIABILITY<br />

AASHTO 93<br />

FUNCTIONAL<br />

CLASIFICATION<br />

INTERSTATE<br />

AND OTHER<br />

FREEWAYS<br />

PRINCIPAL<br />

ARTERIALS<br />

LEVEL OF RELIABILITY<br />

URBAN RURAL<br />

85 – 99.9 80 – 99.9<br />

80 – 99 75 – 95<br />

COLLECTORS 80 – 95 75 – 95<br />

LOCAL 50 - 80 50 - 80

FLEXIBLE PAVEMENT DESIGN<br />

INPUT REQUIRED<br />

AASHTO 93 DRAINAGE COEFFICIENTS<br />

FOR FLEXIBLE PAVEMENTS

FLEXIBLE PAVEMENT DESIGN<br />

CHECK FOR FATIGUE<br />

AASHTO 93<br />

SHELL

RMRC RESEARCH

FLEXIBLE PAVEMENT EMPIRICAL DESIGN METHODS<br />

~ GRANULAR BASE EQUIVALENCY (GBE) FACTORS<br />

ONTARIO EXPERIENCE<br />

• NEW PROJECTS<br />

• HOT-MIX ASPHALT (INCLUDING RECYCLED) 2.0<br />

• GRANULAR BASE (CRUSHED, CBR ≥ 60) 1.0<br />

• GRANULAR SUBBASE (CBR < 60) 0.67<br />

• OGDL (NOT RECOMMENDED) 1.0<br />

• RESURFACING PROJECTS<br />

• OLD HOT-MIX ASPHALT 1.25<br />

• OLD GRANULAR BASE 0.75<br />

• OLD GRANULAR SUBBASE 0.50<br />

• RECONSTRUCTION PROJECTS<br />

• OLD HOT-MIX ASPHALT 1.0<br />

• OLD GRANULAR BASE 0.6<br />

• OLD GRANULAR SUBBASE 0.4<br />

• PULVERIZED RAP/GRANULAR BLEND 1.00<br />

• CIP 1.80<br />

• FOAMED/EXPANDED ASPHALT 1.80<br />

• RUBBLIZED BASE CONCRETE 1.0+

FLEXIBLE PAVEMENT DESIGN<br />

MTO GBE STRUCTURAL DESIGN GUIDELINES FOR FLEXIBLE<br />

PAVEMENTS - SECONDARY HIGHWAYS

FLEXIBLE PAVEMENT DESIGN<br />

LOW TRAFFIC ROAD EXAMPLE<br />

• TRAFFIC<br />

• SUBGRADE<br />

• DRAINAGE CONDITIONS<br />

• ENVIRONMENTAL CONDITIONS<br />

• PAVEMENT SERVICEABILITY<br />

• MATERIALS<br />

AASHTO 93

FLEXIBLE PAVEMENT DESIGN<br />

DARWIN BASED ON AASHTO 93<br />

EXAMPLE LOW VOLUME

FLEXIBLE PAVEMENT DESIGN<br />

AASHTO 93 DARWIN

FLEXIBLE PAVEMENT DESIGN<br />

CHECK FOR FATIGUE<br />

AASHTO 93 SHELL BISAR EXAMPLE COMPLETED

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

DEFLECTION OF PAVEMENT SECTION<br />

IN ADDITION TO THE SEASONAL VARIATIONS, THE DEFLECTION OF A PAVEMENT<br />

SECTION MAY VARY ALONG ITS LENGTH. TO REDUCE THE EFFECT OF BOTH<br />

VARIABLES, A STATISTICAL PROCESS IS USED WHEN ESTIMATING THE MAXIMUM<br />

DEFLECTION.<br />

• DIVIDE THE PAVEMENT INTO SECTIONS WHICH ARE 300M LONG. THE SECTIONS CAN BE<br />

OF VARIABLE LENGTH PROVIDED THEY ARE HOMOGENEOUS WITH RESPECT TO THE<br />

FACTORS WHICH INFLUENCE THE PAVEMENT DESIGN (E.G., SUBGRADE AND TRAFFIC)<br />

• SELECT AT LEAST 10 STRATIFIED TEST POINTS WITHIN EACH SECTION USING A TABLE<br />

OF RANDOM NUMBERS<br />

• OBTAIN THE DEFLECTION MEASUREMENT AT THE SELECTED TEST POINTS USING THE<br />

FALLING WEIGHT DEFLECTOMETER<br />

• CALCULATE THE AVERAGE DEFLECTION (X) AND THE STANDARD DEVIATION (σ x<br />

)<br />

• CALCULATE THE ESTIMATED MAXIMUM PROBABLE DEFLECTION VALUE<br />

D max = ( X + 2σ x )<br />

WATCH FOR OUTLIERS (LOCAL REPAIR), ADJUST FOR SEASON, SPRING ~ 1.5 x FALL,<br />

CONVERT TO STATIC (BENKELMAN BEAM EQUIVALENT), BENKELMAN BEAM ~ 1.5 X FWD

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

FWD<br />

• DEFLECTION<br />

• LAYER MODULI<br />

GRAPHICAL REPRESENTATION OF TYPICAL FWD DEFLECTION BASIN

FLEXIBLE PAVEMENT OVERLAY DESIGN<br />

MTO<br />

ONTARIO PAVEMENT OVERLAY DESIGN CRITERIA<br />

PAVEMENT THICKNESS/DEFLECTION RELATIONSHIP<br />

ASPHALT<br />

INSTITUTE<br />

HAS<br />

SIMILAR<br />

APPROACH

TESTING OF FOAMED ASPHALT AND HMA<br />

PERFORMANCE AND CHARACTERIZATION TESTING<br />

APA<br />

ASPHALT<br />

PAVEMENT<br />

ANALYZER<br />

(PTI)<br />

APA<br />

DESIGN<br />

LABORATORY<br />

PROOF<br />

TESTER<br />

ASPHALT<br />

PLANT<br />

PLACEMENT<br />

LINK BETWEEN LABORATORY TESTING<br />

AND FIELD PERFORMANCE<br />

NAT<br />

RESILIENT MODULUS<br />

PERMANENT DEFORMATION<br />

FATIGUE ENDURANCE<br />

FOR RESILIENT MODULUS OF SUBGRADES AND GRANULAR MATERIALS<br />

JEGEL USES FWD, DCP AND LABORATORY SOIL DYNAMICS TESTING<br />

ASPHALT PAVEMENT ANALYZER AND NOTTINGHAM ASPHALT TESTER IN JEGEL LABORATORY

TECHNICAL LITERATURE INDICATES THE STRUCTURAL<br />

COEFFICIENTS FOR FOAMED ASPHALT ARE GENERALLY<br />

SIMILAR TO THOSE FOR CIR FOR PROPERLY DESIGNED<br />

AND CONSTRUCTED FOAMED ASPHALT STABILIZATION<br />

(QUALITY VERY IMPORTANT)<br />

MTO HIGHWAY 3 CIR COMPLETED IN 1992<br />

1.4 PERCENT HF 150P, CONDITION IN 1997

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

CORES FROM MTO HIGHWAY 3<br />

THE CIR BASE HAS THE APPEARANCE OF HMA

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

MECHANISTIC DESIGN MODULI<br />

GRANULAR BASE EQUIVALENCY (GBE)<br />

• NOTTINGHAM ASPHALT TESTER (NAT)<br />

– RESILIENT PROPERTIES<br />

– LABORATORY AND FIELD SAMPLES<br />

• REPRESENTATIVE FIELD SAMPLES TESTED<br />

– PROJECTS COMPLETED FROM 1991 TO 1996<br />

• MECHANISTIC DESIGN SUBGRADE STRAINS<br />

(BISAR)<br />

• GBE OF ~ 1.8 (a 1 ~ 0.35 - 0.40) NOTE – GBE AND a 1 ARE FOR<br />

PROPERLY DESIGNED AND CONSTRUCTED FOAMED<br />

ASPHALT STABILIZATION (QUALITY VERY IMPORTANT)

CIR STRUCTURAL EQUIVALENCY FACTOR<br />

GRANULAR BASE EQUIVALENCY (GBE) FACTOR INCREASE WITH AGE<br />

OF COLD IN-PLACE RECYCLED ASPHALT

FOAMED ASPHALT STABILIZATION<br />

CHARACTERIZATION IN JEGEL NAT<br />

• RESILIENT MODULUS<br />

• PERMANENT DEFORMATION (RUTTING)<br />

• FATIGUE ENDURANCE

CHARACTERIZATION OF HMA AND FDR (FOAMED ASPHALT) CORES<br />

FROM TYPICAL GEORGIA PROJECTS – BLOUNT CONSTRUCTION<br />

LOCATION AND DEPTH OF CORES SUPPLIED BY CONTRACTOR<br />

GEORGIA<br />

LOCATION<br />

HOUZE WAY<br />

CORE<br />

ID.<br />

AVERAGE LAYER<br />

DEPTH<br />

HMA FOAMED<br />

(mm) ASPHALT<br />

(mm)<br />

DESCRIPTION<br />

H-1 44 125 CENTERLINE EB TURNING LANE INTO FUDDRUCKERS<br />

H-2 35 132 CENTERLINE WB TURNING LANE INTO ROSWELL BICYCLE PATH<br />

H-3 32 118 CENTERLINE WB TURNING LANE INTO 600 HOUZE WAY<br />

TRAMMEL<br />

ROAD<br />

JOTTEM DOWN<br />

ROAD<br />

MCGINNIS<br />

FERRY ROAD<br />

T-1 32 189 CENTERLINE LEFT SIDE, APPROX. 150M FROM PROJECT END<br />

T-2 38 159 CENTERLINE RIGHT SIDE, IN FRONT OF MAIL BOX 3711<br />

T-3 25 150 CENTERLINE LEFT SIDE, IN FRONT OF MAIL BOX 378<br />

J-1 49 156 CENTERLINE OF LANE, IN FRONT OF MAIL BOX 8700<br />

J-2 41 151 CENTERLINE OF LANE, ACROSS FROM MAIL BOX 9030<br />

J-3 50 152 CENTERLINE OF LANE, IN FRONT OF MAIL BOX 7865<br />

M-1 35 120 CENTER TURNING LANE AT WINDWARD RIDGE<br />

M-2 32 152 CENTER TURNING LANE AT JOHN DEERE LANDSCAPE<br />

M-3 25 165 CENTER TURNING LANE AT BROOKWOOD SUBWAY<br />

NOTE: 1. THREE CORES WERE SUPPLIED BY THE CONTRACTOR AT EACH LOCATION DESCRIBED ABOVE.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF FOAMED ASPHALT MIX DESIGN PROPORTIONS<br />

AT VARIOUS PROJECT LOCATIONS<br />

GEORGIA<br />

LOCATION<br />

ASPHALT<br />

MATERIAL<br />

(%)<br />

EXISTING<br />

GRANULAR<br />

(%)<br />

MATERIAL<br />

ASPHALT<br />

CEMENT<br />

(67-22)<br />

(%)<br />

HYDRATED<br />

LIME<br />

ADDITION<br />

(%)<br />

ASPHALT<br />

MATERIAL<br />

(%)<br />

EXISTING<br />

GRANULAR<br />

(%)<br />

MIX<br />

ASPHALT<br />

CEMENT<br />

(67-22)<br />

(%)<br />

HYDRATED<br />

LIME<br />

ADDITION<br />

(%)<br />

TOTAL TOTAL<br />

ASPHALT MOISTURE<br />

CEMENT CONTENT<br />

CONTENT (%) [2]<br />

(%) [1]<br />

HOUZE WAY<br />

(SECTION A)<br />

HOUZE WAY<br />

(SECTION B)<br />

TRAMMEL<br />

ROAD<br />

JOTTEM<br />

DOWN ROAD<br />

MCGINNIS<br />

FERRY ROAD<br />

85.0 15.0 - - 83.1 14.7 2.2 - 6.73 6.3<br />

49.5 49.5 - 1.0 48.2 48.2 2.6 1.0 5.22 5.9<br />

75.0 25.0 - - 73.1 24.4 2.5 - 7.14 6.0<br />

74.5 24.5 - 1.0 73.0 24.0 2.0 1.0 6.72 6.5<br />

- - - - - - - - - -<br />

NOTES: 1. INCLUDING RESIDUAL PLUS ADDED.<br />

2. INCLUDING IN-SITU PLUS ADDED.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

FOAMED ASPHALT MIX DESIGN DATA VS. LABORATORY TESTING RESULTS<br />

AT VARIOUS PROJECT LOCATIONS<br />

GEORGIA<br />

SIEVE<br />

SIZE<br />

PERCENT<br />

PASSING<br />

Section<br />

A,<br />

JMF<br />

HOUZE WAY TRAMMELL ROAD JOTTON DOWN<br />

ROAD<br />

Section Top Lower JMF Top Lower JMF Top Lower<br />

B, FDR FDR<br />

FDR FDR<br />

FDR FDR<br />

JMF Layer Layer Layer Layer Layer Layer<br />

MCGINNIS FERRY<br />

ROAD<br />

JMF Top Lower<br />

FDR FDR<br />

Layer Layer<br />

50.0 mm 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

37.5 mm 100.0 95.8 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

26.5 mm 98.9 91.7 100.0 100.0 100.0 100.0 100.0 100.0 100.0 100.0 - 100.0 100.0<br />

19.0 mm 97.7 82.6 98.6 98.3 97.6 100.0 100.0 97.0 94.7 100.0 - 98.6 98.9<br />

16.0 mm 94.7 77.1 98.2 97.1 94.5 96.9 99.1 94.2 92.2 99.0 - 97.9 98.9<br />

13.2 mm 89.2 73.3 95.7 95.0 91.8 96.0 99.1 92.3 90.2 97.2 - 97.7 98.5<br />

9.5 mm 81.8 68.1 88.8 91.4 86.7 94.1 96.9 89.5 87.6 94.7 - 96.5 95.1<br />

4.75 mm 62.4 49.8 73.4 76.4 60.8 76.4 82.0 72.8 74.9 84.5 - 81.4 77.9<br />

2.36 mm 46.8 39.5 57.4 60.1 43.1 58.2 62.5 61.5 63.5 72.9 - 62.5 60.6<br />

1.18 mm 38.3 34.4 47.1 49.0 34.5 45.7 50.9 54.0 53.9 62.7 - 51.4 49.1<br />

600 µm 31.9 30.6 38.8 40.1 28.6 35.9 43.4 48.3 44.2 51.6 - 44.1 39.5<br />

300 µm 25.3 25.6 30.4 31.1 22.5 26.9 35.8 35.5 32.2 37.3 - 36.4 30.3<br />

150 µm 18.9 19.6 21.2 21.6 15.6 17.2 25.1 24.2 19.4 21.9 - 25.2 19.8<br />

75 µm 13.9 14.4 13.3 14.3 9.9 9.7 15.7 15.5 10.9 12.6 - 15.0 12.0<br />

ASPHALT CEMENT<br />

CONTENT 6.73 5.22 5.83 5.59 7.14 5.97 6.27 6.72 6.03 3.89 - 6.43 5.36<br />

Percent by Mass<br />

AIR VOIDS (%) 8.2 10.1 11.8 14.9 9.8 14.1 14.9 8.9 19.4 24.8 - 15.8 19.4<br />

BRD 2.118 2.100 2.197 2.127 2.198 2.065 2.044 2.091 1.974 1.907 - 2.018 1.956

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF AVERAGE BRD, MRD, AIR VOIDS AND RESILIENT MODULUS<br />

OF ASPHALT CONCRETE SURFACE COURSE, TOP FOAMED ASPHALT<br />

COURSE AND BOTTOM FOAMED ASPHALT COURSE SAMPLES<br />

GEORGIA<br />

SAMPLE<br />

HMA<br />

TOP<br />

FOAMED<br />

ASPHALT<br />

LOWER<br />

FOAMED<br />

ASPHALT<br />

SAMPLE<br />

LOCATION<br />

AVERAGE<br />

BULK<br />

RELATIVE<br />

DENSITY<br />

(BRD)<br />

COMPOSITE<br />

MAXIMUM<br />

RELATIVE<br />

DENSITY<br />

(MRD)<br />

AVERAGE<br />

AIR<br />

VOIDS<br />

(%)<br />

AVERAGE<br />

RESILIENT<br />

MODULUS<br />

@ 20°C<br />

(MPa)<br />

AVERAGE<br />

RESILIENT<br />

MODULUS<br />

AFTER<br />

CONDITIONING<br />

@ 20°C<br />

(MPa) [2]<br />

HOUZE WAY 2.363 2.538 6.9 7957 -<br />

TRAMMEL ROAD 2.303 2.498 7.8 9031 -<br />

JOTTEM DOWN ROAD 2.380 2.492 4.5 7668 -<br />

MCGINNIS FERRY ROAD 2.296 2.535 9.4 4442 -<br />

HOUZE WAY 2.197 2.491 11.8 4804 -<br />

TRAMMEL ROAD 2.065 2.405 14.1 2398 -<br />

JOTTEM DOWN ROAD 1.974 2.450 19.4 2989 -<br />

MCGINNIS FERRY ROAD 2.018 2.396 15.8 3337 -<br />

HOUZE WAY 2.127 2.499 14.9 2540 -<br />

TRAMMEL ROAD 2.044 2.403 14.9 2492 1564<br />

JOTTEM DOWN ROAD 1.907 2.535 24.8 1829 1199<br />

MCGINNIS FERRY ROAD 1.956 2.424 19.4 2566 1786<br />

NOTES: 1. ALL AVERAGE VALUES WERE OBTAINED BASED ON THE TEST OF THREE SAMPLES<br />

EXCLUDING OUTLIERS.<br />

2. LOWER LAYER FOAMED ASPHALT SAMPLES WERE IMMERSED IN WATER FOR 24 HOURS AT<br />

TEMPERATURE RANGED BETWEEN 20 TO 25°C, THEN DRAINED AND DRIED UNDER<br />

LABORATORY AMBIENT AIR FOR 1 HOUR PRIOR TO TESTING.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

SUMMARY OF RESILIENT MODULUS TESTING RESULTS<br />

HOT MIX ASPHALT AND FOAMED ASPHALT MIX<br />

HOUZE WAY, CITY OF ROSWELL, GEORGIA<br />

LAYER<br />

TYPE<br />

AVERAGE RESILIENT MODULUS (MPa)<br />

10°C 25°C 35°C 20°C<br />

HMA 11809 5236 2115 7957<br />

TOP FOAMED ASPHALT 6582 4947 3087 5319<br />

LOWER FOAMED ASPHALT 5831 4536 2566 4457<br />

BOTTOM FOAMED ASPHALT 1970 1639 994 2540<br />

NOTES: 1. ALL RESILIENT MODULUS VALUES WERE OBTAINED BASED ON THE TEST OF THREE<br />

SAMPLES EXCLUDING OUTLIERS.<br />

2. TESTING RESULTS AT 20°C WERE CONDUCTED USING A DIFFERENT SET OF SAMPLE<br />

SPECIMENS FROM THE SAME CORING LOCATION AS THE REST OF THE TESTING<br />

SPECIMENS.

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

RESILIENT MODULUS (MPa)<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

RESILIENT MODULUS VS. TEMPERATURE RELATIONSHIP<br />

HOT MIX ASPHALT AND EXPANDED ASPHALT MIX<br />

(HOUZE WAY, CITY OF ROSWELL, GEORGIA)<br />

HMA<br />

TOP FOAMED ASPHALT<br />

LOWER FOAMED ASPHALT<br />

BOTTOM FOAMED ASPHALT<br />

HMA AT 20°C<br />

TOP FOAMED ASPHALT AT 20°C<br />

MIDDLE FOAMED ASPHALT AT 20°C<br />

LOWER FOAMED ASPHALT AT 20°C<br />

TYPICAL RANGE OF RESILIENT MODULUS<br />

FOR DENSE-GRADED ASPHALT MIXTURES<br />

4000<br />

2000<br />

0<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE (°C)

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

LTPP DESIGN SUMMER PAVEMENT TEMPERATURES ( O C)<br />

98% RELIABILITY<br />

CITY<br />

DEPTH (mm)<br />

0 50 100 150<br />

ATLANTA, GEORGIA 60.1 55.2 52.4 50.5<br />

DETROIT, MICHIGAN 56.4 51.5 48.7 46.8<br />

KANSAS CITY, MISSOURI 60.6 55.7 52.9 50.9<br />

TORONTO, ONTARIO 54.9 50 47.2 45.2

CHARACTERIZATION OF HMA AND FOAMED ASPHALT<br />

RESILIENT MODULUS (MPa)<br />

20000<br />

18000<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

RESILIENT MODULUS VS. TEMPERATURE RELATIONSHIP<br />

HOT MIX ASPHALT AND EXPANDED ASPHALT MIX<br />

(HOUZE WAY, CITY OF ROSWELL, GEORGIA)<br />

HMA<br />

TOP FOAMED ASPHALT<br />

LOWER FOAMED ASPHALT<br />

BOTTOM FOAMED ASPHALT<br />

HMA AT 20°C<br />

TOP FOAMED ASPHALT AT 20°C<br />

MIDDLE FOAMED ASPHALT AT 20°C<br />

LOWER FOAMED ASPHALT AT 20°C<br />

TYPICAL RANGE OF RESILIENT MODULUS<br />

FOR DENSE-GRADED ASPHALT MIXTURES<br />

4000<br />

2000<br />

0<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE (°C)

FOAMED ASPHALT STABILIZATION CHARACTERIZATION IN JEGEL NAT<br />

0.7<br />

AASHTO 93 a 1 STRUCTURAL LAYER COEFFICIENT<br />

FOR HOT-MIX ASPHALT AND FOAMED ASPHALT<br />

0.65<br />

STRUCTURAL LAYER COEFFICIENT a 1<br />

0.6<br />

0.55<br />

0.5<br />

0.45<br />

0.4<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

HMA<br />

UPPER FOAMED<br />

ASPHALT<br />

LOWER FOAMED<br />

ASPHALT<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE ( o C)<br />

a 1 DETERMINED FROM<br />

a<br />

⎡ E ⎤<br />

0.40Log<br />

⎢ 450⎥<br />

⎣ ⎦<br />

RT<br />

1<br />

= +<br />

0.44<br />

a 1 IS DOTTED WHEN GREATER THAN 0.5<br />

AS GIVEN IN FHWA-RD-97-077

FOAMED ASPHALT STABILIZATION CHARACTERIZATION IN JEGEL NAT<br />

2.45<br />

GRANULAR BASE EQUIVALENCY FOR HOT-MIX ASPHALT<br />

AND FOAMED ASPHALT BASED ON MTO (GBE OF HMA = 2)<br />

GRANULAR BASE EQUIVALENCY<br />

2.25<br />

2.05<br />

1.85<br />

1.65<br />

1.45<br />

HMA<br />

UPPER FOAMED<br />

ASPHALT<br />

LOWER<br />

FOAMED<br />

ASPHALT<br />

0 5 10 15 20 25 30 35 40<br />

TEMPERATURE ( o C)<br />

GRANULAR BASE EQUIVALENCY (GBE) OF HOT-MIX ASPHALT<br />

TAKEN AS 2 BASED ON MTO<br />

GBE IS DOTTED WHEN GREATER THAN 2.0

LIFE-CYCLE COST ANALYSIS<br />

“WE GO OUT AND BUY PAVEMENTS LIKE WE WOULD ZUCCHINI.<br />

ALL WE CARE ABOUT IS PRICE.”<br />

DAMIAN J. KULASH, EXECUTIVE DIRECTOR, STRATEGIC<br />

HIGHWAY RESEARCH PROGRAM, 1993

LIFE-CYCLE COST ANALYSIS<br />

• ECONOMIC ASSESSMENT OF COMPETING, TECHNICALLY<br />

SUITABLE SYSTEMS OVER DESIGN LIFE<br />

• COST COMPONENTS<br />

INITIAL COSTS (CAPITAL COSTS)<br />

MAINTENANCE COSTS<br />

REHABILITATION COSTS<br />

RESIDUAL/SALVAGE VALUES<br />

USER COSTS (TRAFFIC DELAY FOR INSTANCE)<br />

• PRESENT WORTH METHOD<br />

ANALYSIS PERIOD (TYPICALLY 30 TO 40 YEARS – AT LEAST ONE<br />

REHABILITATION)<br />

DISCOUNT RATE (TYPICALLY ABOUT 4 PERCENT)<br />

PRESENT WORTH (REMEMBER RULE OF 72)<br />

• FOAMED ASPHALT WITH HMA OVERLAY LIFE-CYCLE COST<br />

ANALYSES GENERALLY VERY FAVOURABLE COMPARED TO<br />

PULVERIZE/'THICKER ' HMA OR MILL/RECYCLED HMA/HMA

LIFE-CYCLE COST ANALYSIS<br />

INITIAL COSTS<br />

LARGELY DETERMINE THE LIFE-CYCLE COST<br />

FOR 20 YEAR PAVEMENT DESIGNS<br />

TYPICAL ONTARIO FDR PROJECT

LIFE-CYCLE COST ANALYSIS<br />

MAINTENANCE COST EFFECTIVENESS<br />

ASSET MANAGEMENT

EXAMPLE OF FOAMED ASPHALT OR CIR<br />

LIFE-CYCLE COST ANALYSIS<br />

• INTEREST RATE 8 PERCENT, INFLATION RATE 4 PERCENT<br />

- DISCOUNT RATE 3.85 PERCENT<br />

• ALTERNATIVES BASED ON EQUIVALENT GRANULAR BASE<br />

EQUIVALENCIES (GBE)<br />

- EXISTING PAVEMENT 100 mm ASPHALT CONCRETE<br />

150 mm GRANULAR BASE<br />

GRANULAR SUBBASE<br />

SUBGRADE<br />

• GBE OF 1.8 USED FOR FOAMED ASPHALT AND CIR<br />

• INITIAL COST OF PAVEMENT STRUCTURE ONLY<br />

- AVERAGE MTO 1996 UNIT PRICES<br />

• MAINTENANCE AND REHABILITATION SCHEDULE BASED ON<br />

JEGEL EXPERIENCE

FLEXIBLE PAVEMENT DESIGN<br />

LIFE-CYCLE COST ANALYSIS<br />

PULVERIZE 200 mm<br />

40 mm HL 8<br />

50 mm OF HL 3<br />

EXAMPLE<br />

FOAMED COLD IN-PLACE ASPHALT<br />

OR RECYCLE CIR 100 mm<br />

50 mm OF HL 3<br />

MILL 40 mm<br />

65 mm OF RECYCLED HL 8<br />

50 mm OF HL 3<br />

INITIAL COST 29,526 31,275 35,700<br />

PRESENT<br />

WORTH OF<br />

MAINT. COSTS<br />

PRESENT<br />

WORTH OF<br />

REHAB. COSTS<br />

PRESENT<br />

WORTH OF<br />

RESIDUAL<br />

COSTS<br />

TOTAL<br />

PRESENT<br />

WORTH OF<br />

COSTS<br />

12,322 13,715 12,332<br />

22,478 8,706 22,478<br />

(10,178) (2,175) (10,277)<br />

54,158 51,521 60,233<br />

RANK 2 1 3

EXAMPLE OF VALUE ENGINEEING<br />

SUPERPAVE PLUS<br />

FOAMED ASPHALT OR CIR AND<br />

SUPERPAVE OVERLAY

AASHTO 2002<br />

AT EARLY IMPLEMENTATION STAGE<br />

GENERAL DESIGN APPROACH<br />

ENVIRONMENT<br />

MATERIALS<br />

<br />

TRAFFIC<br />

PROCESS RAW INPUT FOR DISTRESS MODELING<br />

<br />

ASSEMBLE INPUT AND TRIAL DESIGN<br />

INFORMATION FOR EACH DISTRESS MODEL<br />

<br />

STRESS DEFLECTION ANALYSIS<br />

CALCULATE STRESS ∪ CALCULATE DAMAGE ∪ PREDICT AMOUNT OF DISTRESS<br />

<br />

PREDICT SMOOTHNESS OVER TIME<br />

<br />

CHECK PREDICTED PERFORMANCE<br />

AGAINST DESIGN STANDARDS<br />

<br />

[ REVISE DESIGN AS NECESSARY ]<br />

TO SATISFY DESIGN STANDARD<br />

<br />

DESIGN COMPLETE

QUESTIONS ?<br />

PLEASE CONTACT JOHN EMERY AT JEGEL WITH YOUR QUESTIONS<br />

416-213-1060 jemery@jegel.com www.jegel.com