Anglo American Limited - Mogalakwena Mine ... - SRK Consulting

Anglo American Limited - Mogalakwena Mine ... - SRK Consulting

Anglo American Limited - Mogalakwena Mine ... - SRK Consulting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Anglo</strong> <strong>American</strong> <strong>Limited</strong> -<br />

<strong>Mogalakwena</strong> <strong>Mine</strong> - Final<br />

Environmental Impact<br />

Assessment and Environmental<br />

Management Plan Report for the<br />

Proposed Waste Site project<br />

Report Prepared for<br />

<strong>Anglo</strong> <strong>American</strong> Platinum <strong>Limited</strong> -<br />

<strong>Mogalakwena</strong> <strong>Mine</strong><br />

Report Number 347793/4<br />

DEA reference number: 12/9/11/L621/5<br />

Report Prepared by<br />

August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page i<br />

Final Environmental Impact Assessment and<br />

Environmental Management Plan for the<br />

Proposed Waste Site project<br />

<strong>Anglo</strong> <strong>American</strong> Platinum <strong>Limited</strong> –<br />

<strong>Mogalakwena</strong> <strong>Mine</strong><br />

Private Bag X2463<br />

Mokopane<br />

0600<br />

Limpopo<br />

<strong>SRK</strong> <strong>Consulting</strong> (South Africa) (Pty) Ltd.<br />

265 Oxford Rd<br />

Illovo 2196<br />

Johannesburg<br />

South Africa<br />

e-mail: johannesburg@srk.co.za<br />

website: www.srk.co.za<br />

Tel: +27 (0) 11 441 1111<br />

Fax:+27 (0) 11 880 8086<br />

<strong>SRK</strong> Project Number 347793/4<br />

August 2013<br />

Compiled by:<br />

Olga Nemulenzi<br />

Environmental Scientist<br />

Peer Reviewed by:<br />

Andy Smithen<br />

Partner<br />

Email: onemulenzi@srk.co.za<br />

Authors:<br />

O Nemulenzi; A Owens;<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP Page 1<br />

Executive Summary<br />

Introduction and background<br />

The applicant, <strong>Mogalakwena</strong> Platinum <strong>Mine</strong> (MPM) has currently changed its name to <strong>Anglo</strong><br />

<strong>American</strong> Platinum <strong>Limited</strong> –<strong>Mogalakwena</strong> <strong>Mine</strong> (AAMM). The name MPM was used on the public<br />

documents prepared during the first phase of public participation involvement that is already<br />

completed. However, this report is going to refer to the applicant as AAMM instead of MPM.<br />

AAMM is proposing the development of a waste site on the farm Zwartfontein 818 LR. The waste to<br />

be disposed of at the proposed landfill site will be mainly non-hazardous and domestic waste which<br />

cannot be recycled. Based on the current climatic water balance for the site, it is believed that the<br />

site would be classified as a general communal site, or the smallest site described in terms of<br />

DWAF’s Minimum Requirements for Waste disposal by Landfill (G:C:B-).<br />

The proposed development requires a licence in terms of National Environmental Management:<br />

Waste (Act 59 of 2008) (NEMWA). An Environmental Impact Assessment (EIA) and Environmental<br />

Management Plan (EMP) amendment is required for the environmental authorisation in terms of the<br />

National Environmental; Management Act (NEMA) (Act 107 of 1998). The Department of<br />

Environmental Affairs (DEA) is the competent authority, and the Limpopo Department of Water<br />

Affairs (LDWA) and the Limpopo Department of Economic Development Environment and Tourism<br />

(LDEDET) are the commenting authority for the project.<br />

<strong>SRK</strong> <strong>Consulting</strong> (Pty) Ltd (<strong>SRK</strong>) has been appointed by AAMM as an independent environmental<br />

consultant to carry out an environmental impact assessment (EIA) as required by the National<br />

Environmental Management Act (NEMA) Act 107 of 1998. As such, <strong>SRK</strong> is fulfilling the role of<br />

environmental assessment practitioner (EAP) as specified in the EIA regulations. Included in the EIA<br />

process is the need to develop a draft scoping report (DSR) and final scoping report (FSR), as well<br />

as draft and final environmental impact reports (EIRs). A key component in the finalisation of the<br />

reports is the public participation process which runs throughout the EIA development process.<br />

The application for the project has been accepted by DEA, and has been allocated the following<br />

DEA reference numbers: 12/9/11/L621/5. Key correspondence with DEA relating to the acceptance<br />

of the applications is contained in Appendix F1.<br />

This document represents the Final Environmental Impact Report (FEIR) for the proposed Waste<br />

site. The EIR documents the findings of the impact assessment phase which is part of the EIA<br />

process.<br />

Who is conducting the EIA?<br />

<strong>SRK</strong> <strong>Consulting</strong> has been appointed, as an independent consultant to undertake the EMP/EIA. The<br />

EMP/EIA will be undertaken in the form of an EIA which will be undertaken in two phases: scoping<br />

and assessment. This report is the Final EIR which documents the findings of the second phase<br />

(impact assessment) phase which is part of the EIA process. It will be available for public review and<br />

the stakeholders will have an opportunity to comment on it. Any other comments on the Final EIR<br />

report need to be liaised with DEA.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP Page 2<br />

Who will evaluate the EIA?<br />

Before the proposed AAMM Waste site can be developed, approval has to be obtained from the<br />

regulatory authorities. DEA is the competent authority for the project. The Final EIR will be submitted<br />

to DEA also to the commenting authorities which are LDWA and LDEDET for review. The LDWA will<br />

issue a record of decision in terms of section 49(2) of the NEMWA. DEA will also consult with<br />

various other government departments before making a decision on whether or not to authorise this<br />

project, and to take into account other legislation for example, the National Water Act, the National<br />

Environmental Management: Air Quality Act, the <strong>Mine</strong>s, Health and Safety Act, the Heritage<br />

Resources Act and others.<br />

Project location<br />

The proposed project site is located on the farm Zwartfontein 818 LR, within the foortprint of AAMM<br />

mine near Mokopane in the Limpopo Province. Mokopane falls under <strong>Mogalakwena</strong> Local<br />

Municipality which has its administrative offices in Mokopane. <strong>Mogalakwena</strong> is part of the Waterberg<br />

District Municipality which has its headquarters in Modimolle, approximately 100km to the south<br />

west. Figure 1 shows the location of MPM, the surface lease area in relation to the nearest towns,<br />

and major roads<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP Page 3<br />

Figure 1: Locality map for the proposed Waste site project<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page iv<br />

Project description<br />

The waste site will have a footprint of about 4.6 hectares. The waste to be disposed of at the<br />

proposed landfill site will be mainly non-hazardous and domestic waste which cannot be recycled.<br />

Although paper, plastic, wood and metals are sorted for recycling at the various sections of the mine,<br />

additional sorting will be carried out at the waste site.<br />

The mine plans to temporarily store hazardous waste and salvageable items which contains<br />

hazardous substances in containers in a demarcated enclosed area on the site (less than 10 tonnes<br />

per day). It is envisaged that hazardous waste will comprise fluorescent tubes, laboratory effluent<br />

and soil contaminated with fuel or chemicals, and will total a maximum of 150 cubic metres per<br />

annum.<br />

The mine, as part of its commitment to sound environmental management, also plans to establish a<br />

soil remediation site in the same area. A limited amount of about 20 tonnes of<br />

hazardous/contaminated soil will be transported to the new site where it will be bio-remediated at a<br />

rate of 500kg per day. The purpose of this site is to bio-remediate soils that have been polluted with<br />

hydrocarbons elsewhere on the mining footprint area. The establishment and management of this<br />

site are based on three years of experimental trials on this subject. The waste site is to be operated<br />

by the mine together with a contractor specialising in waste management.<br />

Motivation for the proposed project<br />

The current landfill is nearing its capacity. For AAMM to continue managing their waste properly<br />

there is a need for a new facility that can handle general waste and provide temporary storage for<br />

hazardous waste, a bioremediation facility as well as a waste sorting area. The new waste site will<br />

accommodate waste coming from different sections of the mine when the capacity at the current site<br />

is exhausted.<br />

Proposed project schedule<br />

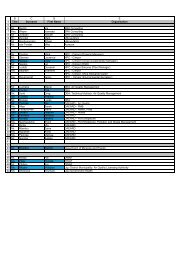

The proposed project schedule is set out in the table below:<br />

Project Stage<br />

Timeframe<br />

EIA Phase and Obtaining of RoD<br />

Construction Phase<br />

Operational Phase<br />

Closure - decommissioning<br />

Closure - post closure<br />

4-5 months<br />

1 year or less<br />

25 years<br />

3-5 years<br />

4-5 years<br />

Baseline environment description<br />

Key aspects of the baseline environment are listed below. A comprehensive baseline description is<br />

provided under Section 4.<br />

Climate<br />

AAMM has a typical summer rainfall climate, receiving the majority of its rainfall in summer in the<br />

period between October and April and having a cool and dry winter.<br />

The region in general has an average maximum monthly temperature of 26.3 °C and an average<br />

minimum monthly temperature of 13.0 °C.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page v<br />

Topography and drainage<br />

The area can generally be described as flat, with granite koppies that gently slope to the west. The<br />

Blinkwater area is drained by the Mohlosana River (Klein Sandsloot) which flows into the Groot<br />

Sandsloot River that drains the region. The Groot Sandsloot runs in a southwesterly direction<br />

draining into the <strong>Mogalakwena</strong> River. The <strong>Mogalakwena</strong> River drains in a northwesterly direction<br />

along the base of the Waterberg Mountains.<br />

Soil and Land Capability<br />

The soils are of moderate to poor quality due to their moderate natural fertility, soil structure, soil<br />

chemical properties, depth and rockiness in places. The soils vary from shallow, rocky sandy loams<br />

to deep, weakly or moderately structured sandy clays. Free lime occurs throughout the site. The<br />

surface rockiness and variable depth, together with the marginal mean annual rainfall and other<br />

climatic conditions, attributes to the low agricultural potential of the soils.<br />

Ecology<br />

AAMM falls into the Savanna Biome. Vegetation types within this biome include Mixed Bushveld and<br />

Clay Thorn Bushveld (Acocks (1953) - Springbok Flats Turf Thornveld). The study area is already<br />

disturbed through activities such as overgrazing, collecting wood for fuel purposes, trampling and<br />

dryland crop production activities.<br />

Surface Water<br />

AAMM is situated in the Limpopo River Catchment Area in quaternary catchment A61G. Streams in<br />

the area are highly seasonal and only flow after larger rainfall events. The Klein Sandsloot and the<br />

Wit River, which confluence with the <strong>Mogalakwena</strong> River drain the Northern extended mine area.<br />

The Mohlosane River flows along the eastern side of the Waste site.<br />

Currently surface water monitoring takes place at two points in the Mohlosane River, namely;<br />

downstream of the Blinkwater Tailings dam and the proposed waste site and downstream of all<br />

mining activities. The upstream Moholosane River monitoring point is the closest current monitoring<br />

point to the proposed landfill site and presents exceedances to the Identified Resource Protection<br />

(IRP) value for sodium and chloride.<br />

Groundwater<br />

Regionally, the water table ranges between 5 – 20 m below ground level, however for the adjacent<br />

boreholes (P122D) are fairly shallow with depths varying from 3 to 8 meters below ground level and<br />

groundwater flow corresponds to the larger regional flow directions and is towards the south southwest<br />

direction, at a velocity of less than 1 m/day. The formations below 50 m contain very little water<br />

and below 250 m may be considered dry. Further details on groundwater are provided in the geohydrological<br />

report contained in Appendix I 1.<br />

Majority of the boreholes directly surrounding the mining areas show elevated electrical conductivity<br />

and Total Dissolved Solids values indicating that mining activities are adding to the salt loads of the<br />

groundwater in the <strong>Mogalakwena</strong> section. Water quality is influenced by the underlying geology and<br />

the impact of human activities in the surrounding communities.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page vi<br />

Air Quality<br />

Dust deposition measurements are usually performed over monthly average sampling periods in<br />

accordance with procedures recommended by the South African Nation Standards (SANS). There<br />

are 14 dust monitoring sites at the mine of which 9 locations have single dust buckets and 5 sites<br />

have single and four directional dust buckets. Dust fallout is generally below the allowed limit, and<br />

highest during the winter season, which is the dry season, and therefore expected.<br />

Archaeology<br />

The surface of the terrain (Waste site) is covered in dense vegetation, especially grass. This area<br />

was formerly ploughed (see locality map) and un-inhabited. It is now a piece of land wedged inbetween<br />

other mining activities, i.e., new administrative buildings, workshops, water pipelines, haul<br />

roads and a large tailings dam that is located to the north and north-east of the terrain. No heritage<br />

material of any nature exists at the terrain.<br />

Socio-Economic Structure<br />

AAMM is located in the <strong>Mogalakwena</strong> Municipal Area, within the Waterberg District Municipality of<br />

the Limpopo Province. The Mapela Tribal Authority that forms part of the <strong>Mogalakwena</strong> Municipal<br />

Area has jurisdiction over the farms AAMM is situated on. This area is largely undeveloped, and is<br />

occupied by a large ‘semi-urban’ and/or rural population where unemployment levels are high.<br />

Noise<br />

A noise survey was done on the site. Despite the fact that mining related industrial noise<br />

characterises the area in general, noise levels at the actual site are below the Occupational<br />

Exposure Levels during the day and at night. In terms of impacts, during construction and<br />

decommissioning, there will be noise related to mobile plant on the site.<br />

Project alternatives<br />

The following alternatives were considered for the proposed Waste site:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Location – where is the best place for specific project infrastructure;<br />

Process/activity/operation – are there other ways of meeting the same objective than the<br />

proposed development;<br />

Scheduling – this can be at what stage of the project for major developments or at what time of<br />

the day for routine, ongoing activities;<br />

Inputs – relating to different possible inputs into the system e.g. different types of chemicals,<br />

different types of building materials, different employment strategies, different designs;<br />

Demand – relating to efficiencies and supply e.g. is there any way of reducing the need for the<br />

proposed development i.e. reducing the demand for platinum; and<br />

No-go option: the option for the proposed development not to take place at all.<br />

Two sites alternatives were determined for the project. More details on the consideration of<br />

alternatives are provided in Section 7.<br />

Public participation process<br />

A public participation process is an integral part of EIA process. The process has included the<br />

notification of interested and affected parties (IAPs) through newspaper advertisements, existing<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page vii<br />

databases, and placement of public notices, public meetings and letters / e-mail communications.<br />

Requisite regulatory timeframes have been complied with and stakeholders have been invited to<br />

review public documents and submit their written comment. Affected communities comprise those of<br />

Ga-Mapela, Ga-Molekana, Ga-Masenya and Ga-Malebana. Key authorities have also been kept<br />

informed of the project.<br />

All issues, comments and suggestions received from stakeholders were reviewed and collated into a<br />

comments and responses report contained in Appendix D 6. The IAPs were given opportunity to<br />

comment on the Draft Scoping report and the Final Scoping report. An opportunity to comment on<br />

the Final EIA Report will be announced by letter, and those comments need to be liaised with DEA.<br />

The FEIA Report and Issues and Response sheets will be left in public places throughout the project<br />

area. The FEIR Report will be available for public review for twenty one days starting from as from<br />

01 August 2013 until 21 August 2013.<br />

Key impacts identified for specialist investigation and assessment<br />

Two new specialist studies and the previous specialist studies conducted for the 2002 EMPr<br />

amendment at the proposed mine expansion area were referred to in order to investigate and assess<br />

the significance of the following potential impacts arising from the prosed developed:<br />

<br />

<br />

<br />

<br />

<br />

Social impacts (including public safety, occupational health and safety)<br />

Soils and land capability impacts (including sterilization of soils and erosion)<br />

Water quality and quantity impacts (including pollution of water resources)<br />

Air quality impacts (including dust generation)<br />

Noise (including noise from movement of vehicles during construction and operation).<br />

The assessment was conducted using <strong>SRK</strong>’s standard methodology for assessing and mitigating<br />

impacts. No fatal flaws were identified and management measures were recommended for the<br />

mitigation and enhancement of negative and positive impacts. The detailed assessment findings are<br />

presented in the DEIR, as well as the environmental management plan.<br />

Opinion on authorisation of project<br />

The landfill at the Waste site is considered a General Waste communal landfill (G:C:B - ). No<br />

significant leachate will be generated in terms of the Site Water Balance (Climatic Water Balance<br />

calculations plus Site Specific Factors), so a leachate management system is not required. The<br />

landfill is anticipated not to produce significant leachate that can have potential to pollute<br />

groundwater. Adverse impacts on the environment are not expected to occur during all phases<br />

(preconstruction, construction, operation and closure) of the project. Proper management and<br />

mitigation measures will be in place to manage the short term impacts such as noise, flies, odour, air<br />

pollution, unsightliness and windblown litter; for example unsightliness and windblown litter will be<br />

limited as the unsorted waste will be kept in the salvage yard which will be enclosed by a concrete<br />

fence.<br />

Long term impacts such as water pollution and gas generation are not anticipated as they are not<br />

associated with this particular landfill. The temporary storage of hazardous waste will however be<br />

undertaken as per guidelines provided in the Miminum requirements waste series. Hazardous waste<br />

at the temporary storage facility will be securely contained during handling, storage and transport to<br />

prevent potential impacts to the environment.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page viii<br />

Since the new landfill site will be situated between existing tailings storage facility, any pollution<br />

generated from the landfill site will be joining the current groundwater flow direction and mix or dilute<br />

with seepage from the tailings facilities. Thus the groundwater pollution by the facility will be<br />

relatively low. The EAP is of the opinion that the management measures proposed will adequately<br />

mitigate potential impacts. The extent of the anticipated cumulative impact such as soil, air and water<br />

will be minimised during preconstruction, construction and operation due to the current monitoring<br />

and remedial management plans that are currently in place.<br />

It can be concluded that the proposed development will comply with the principles of National<br />

Environmental Management: Waste Management Act, 2008 (Act No. 59 of 2008) and the NEMA (Act<br />

No. 107 of 1998), which embraces sustainable development. The public participation process has<br />

been undertaken as per NEMA and the EIA Regulations (2010) as corrected; it is believed that the<br />

issues raised by stakeholders have been adequately addressed.<br />

Environmental impact assessment and environmental<br />

management programme development<br />

AAMM will make every effort, not only to satisfy minimum legal requirements, but strive to minimize<br />

the potential impact the waste site might have on the environment. Detailed plans have been<br />

developed in the Environmental Management Plan (Section 11).<br />

Conclusions and recommendations<br />

This Final EIR report incorporates the following components:<br />

<br />

<br />

<br />

<br />

A description of the EIA process and a detailed plan of study for the EIA.<br />

An outline of the baseline environment, detailed description of the proposed activity<br />

A detailed description of alternative sites as well as process considered to select the preferred<br />

options.<br />

The key issues and concerns raised by stakeholders during the scoping process.<br />

<br />

EAP assessment of the potential impacts of the preconstruction and construction, operational as<br />

well as closure phases of the project.<br />

The project is anticipated to bring sustainable waste management to the <strong>Mogalakwena</strong> mine since<br />

the facility will render waste service such as sorting of waste for reuse and recycling, temporary<br />

storage of hazardous waste as well as disposal of non-hazardous and domestic waste which is<br />

unrecyclable. The mine, as part of its commitment to sound environmental management, also plans<br />

to establish a soil remediation site in the same area. This will reduce the amount of about 20% of<br />

hazardous/contaminated soil that would have been transported to the registered hazardous waste,<br />

Holfontein landfill in Springs, Gauteng.<br />

Findings from the existing data collected by the mine, specialists reports (Geo-hydrological report,<br />

Archaeological and cultural report and Closure plan) and the EAP assessment of the potential<br />

impacts of all phases of the project have addressed concerns raised in the scoping phase. Impact<br />

assessment has been undertaken for both alternative sites for the proposed development. Further,<br />

both alternative sites have been assessed with respect to potential environmental impacts.<br />

Key negative impacts for the proposed site relate to water and soil impacts expected to be<br />

intensively experienced specifically by the operation of the temporary storage of hazardous waste as<br />

well as by the other activities that will occur during construction phase and operation phase.<br />

It is anticipated that it will be possible to successfully manage and mitigate impacts associated with<br />

the development. The EMP includes plans that are incorporated in the detailed design phase, and<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page ix<br />

has been developed as part of the EIA process to manage potential impacts. Programmes and plans<br />

developed and implemented through the EMP will be monitored and audited to ensure compliance.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page x<br />

Figure 2: Location of alternative for the proposed Waste site<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xi<br />

Table of Contents<br />

Executive Summary ..................................................................................................................................... 1<br />

Disclaimer ................................................................................................................................................... xx<br />

List of Abbreviations .................................................................................................................................. xxi<br />

1 Introduction .................................................................................................................. 1<br />

1.1 General Background of the project ..................................................................................................... 1<br />

1.2 Overview of project location and land ownership ............................................................................... 2<br />

1.3 Structure of this report......................................................................................................................... 2<br />

1.4 Project team ........................................................................................................................................ 3<br />

1.4.1 Environmental assessment practitioners ................................................................................ 3<br />

1.4.2 Specialists ............................................................................................................................... 4<br />

1.5 Applicant details .................................................................................................................................. 5<br />

1.6 Key overarching environmental Legislation ........................................................................................ 6<br />

1.6.1 Environmental impact assessment requirements ................................................................... 7<br />

1.6.2 DEA information requirements from the Waste Licence Application form .............................. 9<br />

1.6.3 LDEDET information requirements and the manner in which they are addressed. .............. 12<br />

1.7 Overview of the EIA process ............................................................................................................. 13<br />

1.8 Terms of reference for the EIA .......................................................................................................... 13<br />

1.8.1 Environmental assessment practitioners .............................................................................. 13<br />

1.9 Purpose of the EIA phase ................................................................................................................. 14<br />

1.10 Details of current and previous specialist studies ............................................................................. 14<br />

2 Description of proposed project ............................................................................... 15<br />

2.1 Project overview ................................................................................................................................ 15<br />

2.2 Project location .................................................................................................................................. 15<br />

2.3 Structure of the Waste Site ............................................................................................................... 17<br />

2.3.1 Landfill ................................................................................................................................... 17<br />

2.3.2 Stockpiling ............................................................................................................................. 17<br />

2.3.3 Temporary storage of hazardous waste ................................................................................ 18<br />

2.3.4 Dirty water dam ..................................................................................................................... 18<br />

2.3.5 Bioremediation ...................................................................................................................... 18<br />

2.3.6 Salvage yard ......................................................................................................................... 18<br />

2.3.7 A waste sorting area .............................................................................................................. 18<br />

2.4 Type of waste that AAMM generates ................................................................................................ 18<br />

2.5 Sources of waste ............................................................................................................................... 19<br />

2.6 Transportation of waste .................................................................................................................... 19<br />

2.7 Handling of waste at the waste site .................................................................................................. 19<br />

2.7.1 Scrap metal ........................................................................................................................... 19<br />

2.7.2 General waste ....................................................................................................................... 19<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xii<br />

2.7.3 Contaminated soil .................................................................................................................. 20<br />

2.7.4 Hazardous waste ................................................................................................................... 20<br />

2.8 Project layout .................................................................................................................................... 22<br />

2.9 Project phasing and timing ................................................................................................................ 22<br />

2.10 Infrastructure that will be required for the project ............................................................................. 23<br />

2.11 Construction and duration of the process ......................................................................................... 23<br />

2.12 Operation and duration of the process.............................................................................................. 24<br />

2.12.1 Employment .......................................................................................................................... 25<br />

2.12.2 Monitoring of pollution at the waste site ................................................................................ 25<br />

The locations of the monitoring points are provided in Figure 4-9. ................................................... 26<br />

2.12.3 Accommodation / housing ..................................................................................................... 26<br />

2.13 Water requirements........................................................................................................................... 26<br />

2.13.1 Source of water ..................................................................................................................... 26<br />

2.13.2 Water for construction ........................................................................................................... 27<br />

2.13.3 Water for consumption .......................................................................................................... 27<br />

2.13.4 Water for sanitation ............................................................................................................... 28<br />

2.13.5 Water for bioremediation ....................................................................................................... 28<br />

2.14 Power supply ..................................................................................................................................... 28<br />

2.14.1 Source of power .................................................................................................................... 28<br />

2.15 Solid waste ........................................................................................................................................ 28<br />

2.16 Vehicle access .................................................................................................................................. 28<br />

2.17 Decommissioning, closure and duration of the processes ............................................................... 28<br />

3 Need and desirability of the project .......................................................................... 29<br />

4 Description of the baseline environment ................................................................. 30<br />

4.1 Climate .............................................................................................................................................. 30<br />

4.2 Topography and drainage ................................................................................................................. 30<br />

4.3 Geology ............................................................................................................................................. 30<br />

4.4 Soil and land capability ..................................................................................................................... 33<br />

4.5 Ecology ............................................................................................................................................. 33<br />

4.6 Surface water .................................................................................................................................... 38<br />

4.6.1 Surface water quality ............................................................................................................. 41<br />

4.7 Ground water .................................................................................................................................... 42<br />

4.7.1 Ground water quality ............................................................................................................. 42<br />

4.7.2 Groundwater level and flow direction .................................................................................... 46<br />

4.8 Air quality .......................................................................................................................................... 49<br />

4.9 Site of archaeological and cultural interest ....................................................................................... 54<br />

4.10 Noise 55<br />

4.11 Regional socio-economic structure ................................................................................................... 58<br />

4.12 Regional Context of the <strong>Mogalakwena</strong> Municipality ......................................................................... 58<br />

4.13 Administrative Structures .................................................................................................................. 59<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xiii<br />

4.13.1 Institutional and Organisational Structure of <strong>Mogalakwena</strong> Local Municipality .................... 59<br />

4.13.2 Roles and Responsibilities .................................................................................................... 60<br />

4.13.3 Ward Committee Management ............................................................................................. 61<br />

4.13.4 Community Development Workers (CDWs).......................................................................... 61<br />

4.13.5 Traditional Authority Leaders (TAL) ...................................................................................... 61<br />

4.13.6 Traditional Leadership ........................................................................................................... 62<br />

4.13.7 Community Needs per Settlement ........................................................................................ 63<br />

4.14 Demographics ................................................................................................................................... 63<br />

4.15 Ethnicity and language ...................................................................................................................... 64<br />

4.16 Economic activity .............................................................................................................................. 64<br />

4.17 Income and Poverty levels ................................................................................................................ 65<br />

4.18 Education .......................................................................................................................................... 65<br />

4.19 Health 66<br />

4.19.1 HIV ......................................................................................................................................... 66<br />

4.20 Local Economic Development and Employment .............................................................................. 67<br />

4.21 Housing and services infrastructure .................................................................................................. 67<br />

4.22 Social infrastructure and services ..................................................................................................... 68<br />

5 Potential environmental impacts .............................................................................. 69<br />

5.1 Cumulative impacts ........................................................................................................................... 69<br />

6 Public participation .................................................................................................... 70<br />

6.1 Public Participation Process during Scoping and Impact Assessment Phase ................................. 71<br />

6.1.1 Notification of interested and affected parties ....................................................................... 71<br />

6.1.2 Identification of District and Local Municipality ..................................................................... 71<br />

6.1.3 Identification of relevant Governments Departments ............................................................ 71<br />

6.1.4 Consultation with authorities and landowners ....................................................................... 72<br />

6.1.5 Background information document ....................................................................................... 72<br />

6.1.6 Site notices ............................................................................................................................ 72<br />

6.1.7 Advertisement ....................................................................................................................... 72<br />

6.1.8 Public participation meetings ................................................................................................ 72<br />

6.1.9 Registered interested and affected parties ........................................................................... 72<br />

6.1.10 Obtaining comments from the IAPs ...................................................................................... 72<br />

Submission of Scoping and EIA Reports to Authorities ............................................................................. 73<br />

7 Comparative assessment of alternative identified .................................................. 73<br />

7.1 Consideration of alternative .............................................................................................................. 73<br />

7.1.1 Location alternative 1 (LA1) .................................................................................................. 74<br />

7.1.2 Location alternative 2 (LA2) .................................................................................................. 74<br />

7.2 Process for location alternative selection ......................................................................................... 74<br />

7.3 Advantages and disadvantages ........................................................................................................ 74<br />

7.4 No-go option ...................................................................................................................................... 76<br />

8 Objectives, approach and methodology for the EIA ............................................... 77<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xiv<br />

8.1 Description and timing of the EIA process ........................................................................................ 77<br />

8.2 Project schedule ................................................................................................................................ 78<br />

8.3 Objectives and approach of environmental assessment phase of the EIA process ......................... 78<br />

8.4 The public participation process ....................................................................................................... 79<br />

8.5 Development of the Draft EIR ........................................................................................................... 79<br />

8.6 Availability of the EIR ........................................................................................................................ 79<br />

9 Environmental impact assessment ........................................................................... 81<br />

9.1 List of potential impacts .................................................................................................................... 81<br />

9.2 Methodology for assessment of impacts........................................................................................... 82<br />

9.3 Overview of location alternatives assessed ...................................................................................... 85<br />

9.3.1 Location alternative 1 (LA1) .................................................................................................. 85<br />

9.3.2 Location alternative 2 (LA2) .................................................................................................. 85<br />

9.4 Impact assessments for LA1 ............................................................................................................. 85<br />

9.4.1 Social ..................................................................................................................................... 85<br />

9.5 Impact assessments associated with LA2, which differ from impacts which are the same for both<br />

sites ................................................................................................................................................... 87<br />

9.5.1 Social ..................................................................................................................................... 87<br />

9.6 Impacts rated equally for the two (LA1And LA2) sites ...................................................................... 90<br />

9.6.1 SL4: Contamination of soils .................................................................................................. 90<br />

9.6.2 W1: Deterioration of groundwater quality .............................................................................. 92<br />

9.6.3 W2: Deterioration of surface water quality ............................................................................ 93<br />

9.6.4 AQ 1: Air quality impacts ....................................................................................................... 96<br />

9.6.5 N1: Increased noise .............................................................................................................. 98<br />

9.6.6 -IWM1: Waste management dedicated facility .................................................................... 100<br />

9.7 Cumulative impacts from the development ..................................................................................... 101<br />

10 Environmental impact statement ............................................................................ 102<br />

11 Environmental management plan ........................................................................... 105<br />

11.1 Key definitions used in this EMP ..................................................................................................... 106<br />

11.2 Drafters of the EMPr ....................................................................................................................... 106<br />

11.3 Approach to environmental impact management ........................................................................... 107<br />

12 Responsibility and accountability ........................................................................... 107<br />

12.1 Corporate structure ......................................................................................................................... 107<br />

12.2 Environmental management structure ............................................................................................ 108<br />

12.3 Management contractors ................................................................................................................ 109<br />

12.4 Contractor arrangement during construction and operator ............................................................. 110<br />

12.5 Training awareness and compliance assessment .......................................................................... 110<br />

12.6 Monitoring and compliance assessment ......................................................................................... 111<br />

12.7 Incident handling and reporting ....................................................................................................... 111<br />

12.7.1 Checking and corrective mode ............................................................................................ 112<br />

12.7.2 Corrective actions ................................................................................................................ 112<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xv<br />

12.7.3 Reporting ............................................................................................................................. 112<br />

12.7.4 Management review ............................................................................................................ 112<br />

12.7.5 Liaison ................................................................................................................................. 112<br />

12.7.6 Monitoring and safety .......................................................................................................... 113<br />

13 Overview of development activities ........................................................................ 113<br />

13.1 Planning and design........................................................................................................................ 113<br />

13.2 Pre-construction and construction .................................................................................................. 114<br />

13.2.1 Operation ............................................................................................................................. 114<br />

13.2.2 Construction phase ............................................................................................................. 115<br />

13.2.3 Operation phase .................................................................................................................. 115<br />

13.2.4 Decommissioning and closure ............................................................................................ 116<br />

13.2.5 Schedule ............................................................................................................................. 116<br />

14 Impact mitigation and management ....................................................................... 117<br />

14.1 Links with EIA .................................................................................................................................. 117<br />

14.2 Impact and mitigation / management measures ............................................................................. 117<br />

14.3 Management principles ................................................................................................................... 126<br />

14.3.1 Rationale ............................................................................................................................. 126<br />

14.3.2 Soil conservation and management principle ..................................................................... 126<br />

14.3.3 Air quality management principles ...................................................................................... 127<br />

14.3.4 Conservation and natural habitat management principles .................................................. 127<br />

14.3.5 Noise management principle ............................................................................................... 127<br />

14.4 Management plans.......................................................................................................................... 127<br />

14.4.1 Construction management and control plan ....................................................................... 128<br />

14.5 Operational management and control plan ..................................................................................... 133<br />

14.6 Labour, human resource and social responsibility plan .................................................................. 134<br />

14.7 Health and safety plan .................................................................................................................... 135<br />

14.8 Emergency management and response plan ................................................................................. 136<br />

14.9 Remedial actions ............................................................................................................................. 137<br />

14.10 Rehabilitation and closure management plan ................................................................................. 137<br />

15 Assumption, uncertainties and gaps in knowledge .............................................. 139<br />

15.1 Assumption ..................................................................................................................................... 139<br />

15.2 Uncertainties ................................................................................................................................... 139<br />

15.3 Gaps in knowledge.......................................................................................................................... 139<br />

16 Opinion on authorisation of project ........................................................................ 140<br />

17 Conclusion ................................................................................................................ 141<br />

18 Documents consulted .............................................................................................. 142<br />

Appendices .................................................................................................................... 144<br />

Appendix A: Recent projects undertaken by <strong>SRK</strong> ...................................................... 145<br />

Appendix B: CVs of the EAP team ............................................................................... 146<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xvi<br />

Appendix C: Statement of independence by EAP and current specialists ............... 147<br />

Appendix D: Public participation materials and issues and responses report ........ 148<br />

Appendix D 1: Background Information Document .................................................... 149<br />

Appendix D 2: Text and Photos of site notices ........................................................... 150<br />

Appendix D 3: Proof of Newspaper advertisement ..................................................... 151<br />

Appendix D 4: Copies of comments received ............................................................. 152<br />

Appendix D 5: Minutes from the meeting with the landowners (Langas) and the<br />

attendance register .................................................................................................. 153<br />

Appendix D 6: Issues and response report and attendance registers ...................... 154<br />

Appendix D 7: Telephone Consultation ....................................................................... 155<br />

Appendix E: IAP database ............................................................................................ 156<br />

Appendix F: Key correspondence with competent authority .................................... 157<br />

Appendix F 1: Letter of acceptance for the Waste License application.................... 158<br />

Appendix F 2: Letter of acceptance for the Draft Scoping report ............................. 159<br />

Appendix F 3: Letter of acceptance for the Final Scoping report ............................. 160<br />

Appendix G: Plan of study for EIA ............................................................................... 161<br />

Appendix H: Layout of the project ............................................................................... 162<br />

Appendix I: Specialists reports .................................................................................... 163<br />

Appendix I 1: Geo-hydrological report ......................................................................... 164<br />

Appendix I 2: Closure plan ............................................................................................ 165<br />

Appendix I 3: Socio economic report ........................................................................... 166<br />

Appendix I 4: Ecology report ........................................................................................ 167<br />

Appendix I 5: Air quality report .................................................................................... 168<br />

Appendix I 6: Water management ................................................................................ 169<br />

Appendix I 7: Noise report ............................................................................................ 170<br />

Appendix I 8: Soil and Land capability ........................................................................ 171<br />

Appendix I 9: Archaeology and Cultural Resources report ....................................... 172<br />

Appendix I 10: Risk Assessment Opinion ................................................................... 173<br />

Appendix J: Floodlines ................................................................................................. 174<br />

Appendix K: Waste license Application form .............................................................. 175<br />

Appendix L: Operational plan ....................................................................................... 176<br />

Appendix M: Other waste handling site ....................................................................... 177<br />

Appendix N: Waste hierarchy ....................................................................................... 178<br />

Appendix O: Emergency preparedness ....................................................................... 179<br />

Appendix P: Impact assessment methodology .......................................................... 180<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xvii<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xviii<br />

List of Tables<br />

Table 1-1: Details of specialists’ studies undertaken ......................................................................................... 4<br />

Table 1-2: Key environmental legislation pertinent to the Waste site ................................................................ 6<br />

Table 1-3: Listed activities .................................................................................................................................. 8<br />

Table 1-4: Requested information from the Waste licence application form ...................................................... 9<br />

Table 1-5: Requested information by LDEDET ................................................................................................ 12<br />

Table 2-1: Infrastructure required for the proposed waste site........................................................................ 23<br />

Table 2-2: Activities and duration during construction ..................................................................................... 23<br />

Table 2-3: Activities and duration during operations ....................................................................................... 24<br />

Table 2-4: Groundwater monitoring system at the Waste site (monitoring point, location and frequency of<br />

sampling ..................................................................................................................................... 25<br />

Table 2-5: Newly-drilled boreholes for purposes of abstraction ....................................................................... 26<br />

Table 2-6: Boreholes yield information ............................................................................................................. 26<br />

Table 2-7: Well fields within AMMM ................................................................................................................. 27<br />

Table 2-8: Activities and duration during decommissioning and closure ........................................................ 28<br />

Table 4-1: Summary of current land capability ................................................................................................ 33<br />

Table 4-2: Description of vegetation units ........................................................................................................ 35<br />

Table 4-3: Air quality data collected from January 2013 until May 2013 ......................................................... 50<br />

Table 4-4: Dust fallout standards, targets, action and threshold dust deposition (SANS 1929:2005) ............ 52<br />

Table 4-5: Measurement data ......................................................................................................................... 56<br />

Table 4-6: Day time ambient noise levels ......................................................................................................... 57<br />

Table 4-7: Night time ambient noise level ........................................................................................................ 57<br />

Table 4-8: Villages in proximity to the existing mine and proposed development........................................... 58<br />

Table 5-1: Anticipated impacts associated with the Waste site....................................................................... 69<br />

Table 6-1: Contact details of the District and Local Municipality ...................................................................... 71<br />

Table 6-2: National, provincial, as well as local authorities who have been notified of the availability of the<br />

DEIR ........................................................................................................................................... 71<br />

Table 6-3: Public places at which BIDs were made available ......................................................................... 72<br />

Table 7-1: Evaluation of alternatives ............................................................................................................... 73<br />

Table 7-2: Comparison of implication of development proceeding with LA1 or LA2 ....................................... 74<br />

Table 8-1: Envisaged project schedule ............................................................................................................ 78<br />

Table 9-1: Criteria for assessing significance of impacts ................................................................................ 83<br />

Table 9-2: Positive / negative migration ratings .............................................................................................. 84<br />

Table 10-1: Summary of impacts ................................................................................................................... 103<br />

Table 11-1: Key definitions used in the EMPr ............................................................................................... 106<br />

Table 11-2: Approaches to impact management .......................................................................................... 107<br />

Table 12-1: Responsibilities of staff involved in environmental management at AAMM Waste site ............. 109<br />

Table 14-1: Mitigation and management measures relating to impacts caused by project activities during all<br />

project phases. For further detail refer to the relevant sections noted under ‘principles’ and<br />

‘plans’ ....................................................................................................................................... 118<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xix<br />

List of Figures<br />

Figure 2-1: Locality map for the proposed Waste site project ......................................................................... 16<br />

Figure 2-2: <strong>Anglo</strong> <strong>American</strong> <strong>Mogalakwena</strong> <strong>Mine</strong> Waste flow Chart ................................................................ 21<br />

Figure 4-1: Geology of the area ........................................................................................................................ 32<br />

Figure 4-2: Vegetation cover map in relation to the proposed project area ..................................................... 37<br />

Figure 4-3: Summary of hydrology at the project site (Aqua earth, 2012) ....................................................... 39<br />

Figure 4-4: Surface water monitoring points in relation to proposed project area............................................ 40<br />

Figure 4-5: Mohlosana River monitoring points water quality chart ................................................................ 41<br />

Figure 4-6: Upstream Mohlosane River monitoring point data trend analysis ................................................ 42<br />

Figure 4-7: landfill position and position of the groundwater monitoring boreholes ......................................... 44<br />

Figure 4-8: Groundwater quality results from boreholes adjacent to the proposed landfill site ...................... 46<br />

Figure 4-9: Location of project’s adjacent boreholes and direction of groundwater flow ................................. 47<br />

Figure 4-10: Background boreholes and groundwater levels from 2011 Groundwater modelling (Aqua earth,<br />

2012) .......................................................................................................................................... 48<br />

Figure 4-11: Dust Monitoring results ............................................................................................................... 52<br />

Figure 4-12: location of dust buckets in relation to the project site .................................................................. 53<br />

Figure 4-13: The current view of the site .......................................................................................................... 54<br />

Figure 4-14: Day time ambient noise level ....................................................................................................... 57<br />

Figure 4-15: Night time ambient noise levels ................................................................................................... 58<br />

Figure 4-16: Institutional and Organisational Structures of <strong>Mogalakwena</strong> Local Municipality ......................... 60<br />

Figure 4-17: Roles and Responsibilities of each of the departments within the <strong>Mogalakwena</strong> Local<br />

Municipality. ............................................................................................................................... 61<br />

Figure 4-18: Traditional authority leaders ........................................................................................................ 62<br />

Figure 4-19: Traditional communication structure ............................................................................................ 63<br />

Figure 4-20: Graphical representation of <strong>Mogalakwena</strong> Municipality Population ........................................... 64<br />

Figure 4-21: Health care facilities in the <strong>Mogalakwena</strong> Municipality ............................................................... 66<br />

Figure 6-1: Public participation steps for the consolidated EIA process being undertaken for the Waste site<br />

projects ....................................................................................................................................... 70<br />

Figure 7-1: Location of alternative Waste sites LA1 and LA2 (preferred one) ................................................ 75<br />

Figure 9-1: Significance Rating Matrix ............................................................................................................. 83<br />

Figure 12-1: Proposed organizational structure for AAMM Waste site Project showing the position of staff<br />

involved in environmental management .................................................................................. 108<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xx<br />

Disclaimer<br />

The opinions expressed in this Report have been based on the information supplied to <strong>SRK</strong><br />

<strong>Consulting</strong> (South Africa)(Pty) Ltd (<strong>SRK</strong>) by <strong>Anglo</strong> <strong>American</strong> Platinum <strong>Limited</strong> <strong>Mogalakwena</strong> <strong>Mine</strong><br />

(AAMM). <strong>SRK</strong> has exercised all due care in reviewing the supplied information. Whilst <strong>SRK</strong> has<br />

compared key supplied data with expected values, the accuracy of the results and conclusions from<br />

the review are entirely reliant on the accuracy and completeness of the supplied data. <strong>SRK</strong> does not<br />

accept responsibility for any errors or omissions in the supplied information and does not accept any<br />

consequential liability arising from commercial decisions or actions resulting from them. Opinions<br />

presented in this report apply to the site conditions and features as they existed at the time of <strong>SRK</strong>’s<br />

investigations, and those reasonably foreseeable. These opinions do not necessarily apply to<br />

conditions and features that may arise after the date of this Report, about which <strong>SRK</strong> had no prior<br />

knowledge nor had the opportunity to evaluate.<br />

NEMO/SMTN G:\347793 Mokgalekwena 2010\7Reports\Final EIR\<strong>SRK</strong> website\Main report\Waste site Final EIR_Aug 2013.docx August 2013

<strong>SRK</strong> <strong>Consulting</strong>: 347793: Waste site FEIA & EMP<br />

Page xxi<br />

List of Abbreviations<br />

AAMM<br />

<strong>Anglo</strong> <strong>American</strong> Platinum <strong>Limited</strong> - <strong>Mogalakwena</strong> <strong>Mine</strong><br />

AQMP<br />

Air Quality Management Plan<br />

BBBEE<br />

Broad Based Black Economic Empowerment<br />

BID<br />

Background Information Document<br />

CDW<br />

Community Development Workers<br />

DEA<br />

Department of Environmental Affairs<br />

DEIR<br />

Draft Environmental Impact Report<br />

FEIR<br />

Final Environmental Impact Report<br />

DSR<br />

Draft Scoping Report<br />

DWAF<br />

Department of Water Affairs and Forestry<br />

DWD<br />

Dirty Water Dam<br />

EAP<br />

Environmental Assessment Practitioner<br />

ECO<br />

Environmental Control Officer<br />

EIA<br />

Environmental Impact Assessment<br />

EMP<br />

Environmental Management Plan<br />

EMPr<br />

Environmental Management Plan report<br />

FEIR<br />

Final Environmental Impact Report<br />

FSR<br />

Final Scoping Report<br />

G:CB-<br />

General Communal site<br />

GDP<br />

Gross Domestic Product<br />

HSE<br />

Health and Safety Environment<br />

IAPs<br />

Interested and Affected Parties<br />

IDP<br />

Integrated Development Plan<br />

IES<br />

Independent Environmental Specialist<br />

IRP<br />

Identified Resource Protection value<br />

ISO<br />

International Organization for Standardization<br />

IWWMP<br />

Integrated Water and Waste Management Plan<br />

LDEDET<br />

Limpopo Department of Economic Development<br />

Environment and Tourism<br />

LDWA<br />

Limpopo Department of Water Affairs<br />

LED<br />

Local Economic Development<br />

MLM<br />

<strong>Mogalakwena</strong> Local Municipality<br />

MPM<br />

<strong>Mogalakwena</strong> Platinum <strong>Limited</strong><br />

NEMA<br />

National Environmental Management Act<br />

NEMAQA<br />

National Environmental Management – Air Quality Act<br />

NEMWA<br />

National Environmental Management – Waste Act<br />

NGL<br />

National Ground Level<br />

NWA<br />

National Water Act<br />

OEL<br />

Occupational Exposure Limits<br />

OHS Act<br />

Occupational Health and Safety Act<br />

PGM<br />

Platinum Group <strong>Mine</strong>rals<br />

PPL<br />

Potgietersrus Platinum <strong>Limited</strong><br />

SANS<br />

South African National Standards<br />

SLP<br />

Social and Labour Plan<br />

<strong>SRK</strong><br />

Steffen Robertson and Kirstin <strong>Consulting</strong> Company<br />

TRP<br />

Tailing Retreatment Plant<br />

TAL<br />

Traditional Authority Leaders<br />