mogalakwena mine waste managment strategy - SRK Consulting

mogalakwena mine waste managment strategy - SRK Consulting

mogalakwena mine waste managment strategy - SRK Consulting

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PLATINUMMOGALAKWENA MINEWASTE MANAGMENT STRATEGYJune 2011………………………….Environmental Coordinator………………………….SHE Manager………………………….Manager North Concentrator………………..Date………………..Date………………..Date…………………………Manager South Concentrator………………..Date…………………………General Manager………………..Date1

PLATINUMCONTENTS1. INTRODUCTION 32. SCOPE 43. WASTE CATEGORIZATION, CLASSIFICATION & QUANTIFICATION 53.1. IDENTIFICATION AND CLASSIFICATION 54. PERMITTING REQUIREMENTS 174.1 REVISED ACTION PLAN FOR LICENSE AUTHORISATION.185. WASTE MINIMISATION, RE-USE & RECYCLING; AND TARGETS 1186. SAWIS REPORTING217. WASTE TREATMENT AND DISPOSAL22Table 1. Waste Categorisation, Classification Action PlanTable 2. Waste products that have been excluded from this<strong>waste</strong> management <strong>strategy</strong> and reasons for their exclusion.Table 3. Mogalakwena <strong>waste</strong> streams.Table 4. The general non hazardous <strong>waste</strong> found at Mogalakwena PlatinumMine and their end point.Table 5. The recyclable non hazardous <strong>waste</strong> found at Mogalakwena PlatinumMine, site management and the end point or product of the re-cyclingprocess.Table 6. The different hazardous <strong>waste</strong> types found at Mogalakwena Mine, theircurrent disposal methods and controls.Table 7. The Anglo Platinum Permitting Requirements Action Plan 2011Table 8. Mogalakwena Mine Revised Action Plan, May 2011.Table 9. Anglo Waste Minimisation, Re-Use & Recycling Action Plan.Table 10. SAWIS Reporting Action Plan 2011.Table 11. Waste Treatment And Disposal Action Plan 2011.2

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________1. INTRODUCTIONThe elimination of <strong>waste</strong> in its entirety will not be feasible but through the systematicapplication of the <strong>waste</strong> hierarchy (see figure 1) it might be possible to reach a point in futurewhere recovery, reuse and recycling and alternative disposal technologies overtake landfillsas preferred means of disposal. The <strong>strategy</strong> seeks to provide norms and standards toensure group uniformity in managing <strong>waste</strong>.Figure 1: <strong>waste</strong> hierarchy (NWS)Action plans will be instituted to ensure compliance with the <strong>waste</strong> <strong>strategy</strong>. Figure 2 showsthat the <strong>waste</strong> <strong>strategy</strong> aims to change our current practice where disposal to landfill formsthe major component of our <strong>waste</strong> management, to focus on <strong>waste</strong> reduction with disposal asa last resort only.Figure 2: Journey towards an ideal <strong>waste</strong> hierarchy3

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________2. SCOPEThis document is applicable to Mogalakwena Mine including the <strong>mine</strong> and two concentrators.This <strong>waste</strong> <strong>strategy</strong> addresses the Hazardous and Non-hazardous <strong>waste</strong> management asidentified in the National Environmental Management: Waste Act. no.59 of 2008. Thefollowing elements will be considered:• Waste stream identification, catégorisation, classification & quantification;• Permitting requirements as per legislation ;• Waste Minimisation, Reuse & Recycling; and target setting;• Internal (SHE database) and external (SAWIS) Reporting ;• Waste Disposal and treatment.4

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________3. WASTE CATEGORIZATION, CLASSIFICATION & QUANTIFICATIONObjectives:• Identify all different <strong>waste</strong> streams• Categorise all different <strong>waste</strong> types• Proper management of the different <strong>waste</strong> types• Waste manifest system (records and quantities) is required to track hazardous <strong>waste</strong>management cycle from generator, transport and final management.• Waste must not be mixed or diluted.• Waste must be managed within 3 months (i.e. no indefinite storage of <strong>waste</strong>).• Consideration of the MSDS on the hazardous material <strong>waste</strong> productsSchedule 1: Pre-classified WasteGeneral Waste• Domestic <strong>waste</strong>;• Building and Demolition <strong>waste</strong>;• Inert <strong>waste</strong>;• Business <strong>waste</strong> (except with components that maybe hazardous);• Waste tyres;• Garden <strong>waste</strong>;• Post consumer packaging (paper, plastic, glass);• Animal carcassesHazardous Waste• Health Care Risk Waste (HCRW);• Asbestos Waste;• General <strong>waste</strong> contaminated with hazardous<strong>waste</strong> / chemicals3.1. Identification and classification of <strong>waste</strong>.Table 1.Waste Categorisation, Classification Action PlanWASTE CATEGORIZATION, CLASSIFICATION ACTION PLANActivities Who? When?Deter<strong>mine</strong> all <strong>waste</strong> generated on site and compile a <strong>waste</strong>inventory,Environmentalcoordinators (ECs)CompletedMay 2011Ensure those <strong>waste</strong> which fall outside schedule 1 are classified inCompletedECsaccordance with SANS 10234:2008May 2011Ensure effective <strong>waste</strong> separation at the source of <strong>waste</strong> generation Environmentalby putting correct telecoms/<strong>waste</strong> paddockscoordinators (ECs)OngoingEnsure effective separation of <strong>waste</strong> through continuous awareness Environmentaland training of all personnelcoordinators (ECs)Ongoing5

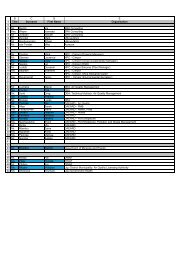

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Water Treatment445Hazardous materialstore 486Compressed aircircuitOffices includingprotection servicesat the gate andporta cabinsTraining centre.x x x x x x x xx x x x x x x x x xx x x x x x x x xx x x x x x x xStores x x x x x x x x x xWorkshops x x x x x x x x x x x xTransformers x x x xGeneralContractorsx x x x x x x x x x x x xChange Area x xTransport to thesmeltersx x x x x x x xVehicles (all) x x x x x x x x xSalvage area /<strong>waste</strong> transfer areaSOUTH CONCENTRATORx x x x x x x x x x x xWorkshops (all) x x x x x x x x x x x xChange houseLaundryxShower Rooms x xConcentrator Plant x x x x x x x x x xSubstations andtransformersHazardous WasteDisposal SitePlant, machineryand otherequipment: inc.Hazardousmaterials stores.Plant, machineryand otherequipmentInstrumentationWorkshopx x xX X X X X X Xx x x x x x x x xx x x x x x x x x x xx x x x x x x x x x XAssay Lab x x x x x x x XCooling Towersincl cleaningx x x8

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Sewage Plant x x x x x XWater softenerplantLDV FuelDispensingx x xx x x x x xMetallurgy x x x x xConcentratetransportationx x x x x x x xFiltration x x x x x xFlotation x x x x x x x x x XMetallurgicalLaboratoryx x x x x xMilling x x x x x xReagent mixingand storagex x x x x xWash Bay x x x x x xCanteen x xHealth centre andClinicMININGx x x x x xExploration drilling x x x x xxHuman ResourceManagementProcurement x x x x x x xSHEBulk Oil StorageTanks (Shell)Workshops (allgeneral)xx x x xx x x x x x x x x x x xLDV Workshop x x x x x x x x x xMining Engineering x x x x x x x x x x x xRoad Works x x x xHanwill Contractor x x x x x x xx x x x x x x x xTerex ShovelWorkshopTrentyre x x x x x x x x x xMetallurgy x x x x x xBlasting x x x xCanteen / eatingareasxx9

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Ablutions andChange House(s)xClinic x x x xLaundry room x x x x xPPE Store x x x x xWaste sortingareasx x x x x x x x x x x xSalvage yards x x x x x x x x x x x xLaboratory x x x x x x x x x x x xWater treatmentplantSewage treatmentplantsx x x x xx x x10

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Table 4.The general non hazardous <strong>waste</strong> found at MogalakwenaPlatinum Mine and their end point.TypeAreaFood / catering <strong>waste</strong> Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.Domestic <strong>waste</strong> Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.Garden <strong>waste</strong>Gardens, Cleaning vegetationfrom Concentrator and MineWorkshop sites.Current Site managementand disposalGeneral Non Hazardous WasteCollected in White Bins orSkips and taken to theLandfill Site by FELAWaste.Collected in White Bins or Landfill Site.Skips and taken to theLandfill Site by FELA Wastewhere sorting takes place.A log book records thenumber of skips tipped atthe Landfill Site and theamount of recyclablesremoved from site.Collected in White Bins or Landfill Site.Skips and taken to LandfillSite by FELA Waste. A logbook records the number ofskips tipped at the LandfillSite.End Point or recycledproduct.Very small volumes of <strong>waste</strong>food are taken to the LandfillSite.Building rubble Mogalakwena Mine, Collected in White Skipsand taken to the LandfillLandfill Site. Often used toconstruct berms and to coverSite by FELA Waste. A log compacted <strong>waste</strong>.book records the number ofskips tipped at the LandfillSiteTable 5.The recyclable non hazardous <strong>waste</strong> found at MogalakwenaPlatinum Mine, site management and the end point or product ofthe re-cycling process.TypeAreaCurrent Sitemanagement anddisposalEnd Point and / or therecycled product.Recyclable <strong>waste</strong>PaperTins (cool drink)Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaSorted into Orange trolleybins, Orange Cages andWhite Skips at source.Resorted at the LandfillSite.Security monitor loads andissue Way Bills for theloads removed from site.Sorted into Blue TrolleyBins or White Skips atsource.From site, paper and boxesare taken directly to Anti-Waste Mokopane andweighed.Weights are forwarded toFela Waste for inclusion inthe SHE database.Anti Waste are an agent forMondi.From site, the cans are takendirectly to Anti-WasteMokopane and weighed.11

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________PlasticMetalNorth Concentrator.Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.Mogalakwena NorthConcentrator, MogalakwenaSouth Concentrator, SalvageYardCans are counted. Securitymonitor loads and issueWay Bills for the loadsremoved from site.Sorted into Green TrolleyBins or White Skips atsource.Plastic bottles are counted.Security monitor loads andissue Way Bills for theloads removed from site.Weights are forwarded toFela Waste for inclusion inthe SHE database. AntiWaste crush and forward toCollect-A-Can in Pretoria.From site, the plastic is takendirectly to Anti-WasteMokopane and weighed.Weights are forwarded toFela Waste for inclusion inthe SHE database. AntiWaste crush and forward toExtrupet in JohannesburgSmall items are sorted into Metals are resorted atBlack Skips and forwarded Nieuwco Steelwith larger items to thenearest Salvage Yard. Send onwards to Mittal Steel.Wood (especiallypallets)Mogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.FELA Waste hassubcontracted the collectionof metal <strong>waste</strong> to NieuwcoSteel.Security monitor loads andissue Way Bills for theloads removed from site.Wood is stored in theSalvage Yard, where it issorted and removed fromsite by FELA Waste.Contaminated wood isremoved and processedwith hazardous materials.Clean wood is removedfrom site whole.Security monitor loads andissue Way Bills for theloads removed from site.Salvageable items Salvage yard Sold at scrap sales or bytender.Way Bills are issued uponpayment.Conveyor belting andrubber includinghydraulic hoses.Small tyres.Mogalakwena Mine,Mogalakwena NorthConcentrator, MogalakwenaSouth ConcentratorFELA Waste hassubcontracted the collectionof conveyor belting toNieuwco Steel.Security monitor loads andissue Way Bills for theloads removed from site.Small tyres are transportedoff site to recognisedClean wood is taken tostorage at a plot owned byFela Waste.Pallets are rehabilitated andsold.Some wood is sold toindividual buyers for shacks,furniture etc.The balance is stockpileduntil it is worthwhile bringing aheavy duty chipper to site.Nails are separated andrecycled, while sawdust issent for composting.Nieuwco Steel stockpileconveyor belting at their sitein Mokopane. Long lengthsare sold and small cuts areused in bakkies etc.There is not much of a marketat this time for scrapconveyor belting.Off cuts can be processed in12

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________recyclers by theEngineering section.kilns when available.A new process for recyclingthe metal and rubber fromhydraulic hoses is in trial.Electrical cable Electrical workshops Collected in Orange Skipsor drums and stored at theElectrical Salvage Yard.FELA Waste hassubcontracted the collectionof metal <strong>waste</strong> to NieuwcoSteel.Results may be expected inJuly 2011.Metal cores are strippedaway and sold by NieuwcoSteel.Polyurethane screenPanelsMogalakwena Mine,Mogalakwena NorthConcentrator, MogalakwenaSouth ConcentratorSecurity monitor loads andissue Way Bills for theloads removed from site.The metal and rubberscreens are stockpiled inthe Salvage Yard forcollection by the suppliers.Some are sent to aHazardous Landfill becausethey can’t be separated.A new process for recyclingthe metal and rubber from thescreens is in trialPlastic containers(e.g. 25 litre drumsand buckets)Mogalakwena Mine,Mogalakwena NorthConcentrator, MogalakwenaSouth ConcentratorSewageMogalakwena Mine,Mogalakwena SouthConcentrator, MogalakwenaNorth Concentrator.Dried Sewage Sludge Sewage worksMost are Collected by thesuppliers.Fela Waste remove othercontainers from site.Treated in the sewageworks and <strong>waste</strong> water isreturned back to theprocessing cycle.Loaded periodically intoWhite Skips and taken tothe Landfill Site by FELAWaste.Results may be expected inJuly 2011.Washed at Eco Mokopaneand reused for collectingother <strong>waste</strong>Run and monitored by theHygiene Department.Landfill Site. Often used toconstruct berms and to covercompacted <strong>waste</strong>.Table 6.The different hazardous <strong>waste</strong> types found at Mogalakwena Mine,their current disposal methods and controls.Type Area Current Disposal Control MeasuresHazardous WasteOil Sludge / spilled oil Mogalakwena Platinum Mine Oil Separations Service Safe Disposal Certificatesworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andcollects sludge from oiltraps and oil contaminatedsoil, for disposal at eitherHolfontein or Ekurhuleni,from the registered landfillsite and Oil SeparationServices will be handed in tothe Environmentalworkshops. Ultra City,Contractor Sites, Materialsregistered hazardous <strong>waste</strong> Coordinator and Filedlandfill sites.13

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Type Area Current Disposal Control MeasuresDepartmentExpired or SpilledChemicals /ReagentsMogalakwena Platinum Mineworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City,Metallurgical Laboratories,Materials Department,Workshops, Analytical Lab.The Health Section hasdeveloped and maintainsthe Chemalert database.An extensive database forall substances which enterthe <strong>mine</strong>. The databasecontains a wide amount ofinformation on eachsubstance or product andrecords the suppliers MSDSfor each, including theSANS 10234:2008classification and codes.The database can generatean inventory of all sitebased, or Anglo groupsubstances on record.Oil Separation Servicescleans up spilledchemicals/reagents fordisposal at Holfontein orEkurhuleni, registeredhazardous <strong>waste</strong> landfillsites.MSDS are posted for eachsubstance at the variousworkshops where bulkproducts are used. Theseguide the safety and clean-upprocess for all concerned.Safe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.Suppliers are contacted bythe Materials Department toremove expired chemicals /reagents.Lead Oxide Analytical Lab Oil Separation Servicescollects lead oxide from thelab for disposal atHolfontein or Ekurhuleni,registered hazardous <strong>waste</strong>landfill sites.Small Ceramic Analytical Lab..Cupels (contaminatedwith lead) and slagUsed RadioactivesourcesEmpty chemicalcontainersMogalakwena SouthConcentrator, MogalakwenaNorth Concentrator,Analytical Lab.Mogalakwena Platinum Mineworkshops, MogalakwenaOil Separation servicescollects the small ceramiccupels and slag from theAnalytical Lab.Large cupels are collectedand taken to the <strong>mine</strong>landfill site.Refer all concerns to thelegal appointees for GroupIV hazardous substancesSent to MaterialsDepartment and then to theThe toxicity of all cupels <strong>waste</strong>sted and reported, by theCSIR in 2003.Safe Disposal Certificatesfrom the registered landfillsites (Haulfontein has aspecific dump site) and OilSeparation Services will behanded in to theEnvironmental Coordinatorand Filed.Safe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.14

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Type Area Current Disposal Control MeasuresSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City,Metallurgical Laboratories,Materials Department,Workshops, Analytical Lab.suppliers or collecteddirectly by the supplier orOil Separation ServicesFluorescent tubesMercury vapor andother specialist bulbs.Oil and Degreaserdrums.Waste contaminatedby hazardoussubstancesOffices and workshops.Security spotlights.Oil Separations Servicescollects crushed fluorescenttubes from the offices andworkshops at Process andMiningEntire Mogalakwena Section Collected in brown teleconskips and at the salvageyard for collection by OilSeparation Services.Mogalakwena Platinum Mineworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City,Metallurgical Laboratories,Materials Department,Workshops, Analytical Lab.Contractor Sites.Collected in brown telekonskips for collection by OilSeparation ServicesMedical <strong>waste</strong> Clinic Collected for removal bySANUMED.Anti freezeUsed LubricantsSludgeMogalakwena Platinum Mineworkshops, Contractor Sites.Mogalakwena Platinum Mineworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City.Contractor SitesMogalakwena Platinum Mineworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City.Contractor Sites. Random oilspills across the site.From the workshops, antifreeze drains into a pollutioncontrol dam, where it isdiluted. From the dam, itcan be put onto the roads,or into pits for collection withsludge.Oil Separation Servicescollects used lubricants intankers.At oil separation services,oils and water areseparated out through aseries of tanks. Oil isresold.Oil Separation Servicescollects sludge andcontaminated soils in 200kgdrums.At oil separation services,oils and water areseparated out through aseries of tanks. Oil isresold. Sludge is dried andsent to Haulfontein.Safe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.Drums are cleaned and usedfor the removal of other <strong>waste</strong>oils from the site by OilSeparation Services.Safe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.Safe Disposal Certificatesfrom SANUMED for ClinicrecordsIf a dedicated tank isavailable, it can be collectedand taken to landfill, orrecycled on plant.The management andrecycling of anti freeze is apossible new project for AO.Tankers are weighed on siteand the <strong>mine</strong> issues weighbills.Drums are counted orweighed on site and the <strong>mine</strong>issues weigh bills. (1 drum =200kg from trial)Safe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.15

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Type Area Current Disposal Control MeasuresItems contaminatedwith oilSample <strong>waste</strong> fromthe labsMogalakwena Platinum Mineworkshops, MogalakwenaSouth Concentrator andworkshops, MogalakwenaNorth Concentrator andworkshops. Ultra City.Contractor Sites.Analytical Lab, Met LabCollected by Oil SeparationServicesStored in white telecon skipoutside Analytical Lab andthen sent back to the plantVehicle Batteries Vehicle Workshops Sent to the Salvage Yardand then traded for newones with the supplierSafe Disposal Certificatesfrom the registered landfillsites and Oil SeparationServices will be handed in tothe EnvironmentalCoordinator and Filed.Very small quantities.Records kept at MaterialsDepartment16

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________4. PERMITTING REQUIREMENTSAnglo Platinum has proposed an assessment methodology that could assist operations inorder to deter<strong>mine</strong> whether a legal obligation arises to obtain a <strong>waste</strong> management license inrespect of a particular activity or <strong>waste</strong> type. The two phased assessment to deter<strong>mine</strong>whether the Waste Act applies can therefore be illustrated as follows:Q1: Is the <strong>waste</strong>matter one of thefollowing:Debris, discard, tailings, slimes,screening, slurry, <strong>waste</strong> rock, foundrysand, beneficiation plant <strong>waste</strong>YesWasteAct doesnot applyQ2: If not, is the<strong>waste</strong> matter:Any other <strong>waste</strong> product which is objectivelyviewed as forming a legitimate part of the miningapplication concerned with mining of a <strong>mine</strong>ral orany activity directly incidental thereto.WASTE ACT APPLIES: FURTHER ASSESSMENTREQUIREDNoIs it <strong>waste</strong> as defined in theWaste Act?YesIs it a listed <strong>waste</strong> management activity?YesNoNoWastemanagementlicence notrequiredIs it lawful?YesNoWaste Management LicenserequiredAll operations are therefore required to deter<strong>mine</strong> whether the <strong>waste</strong> Act applies by doing theassessment before end of March 2011. Those that are found to have landfill/storagecapacities which are above the required thresholds will apply for <strong>waste</strong> authorisation in termsof the Waste Act.17

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________Table 7. The Anglo Platinum Permitting Requirements Action Plan 2011ANGLO PERMITTING REQUIREMENTS ACTION PLAN 2011Confirm <strong>waste</strong> storage capacities per <strong>waste</strong> type/categoryActivities Who? When?Deter<strong>mine</strong> whether the Waste Act applies by doing the assessmentas per above.Apply for <strong>waste</strong> authorization in terms of the Waste Act, if found tobe above thresholdsECsECsCompletedMarch 2011CompletedMarch 2011ECs December 20114.1 REVISED ACTION PLAN FOR LICENSE AUTHORISATION.In following the above procedure to assess <strong>waste</strong> areas, the situation on Mogalakwena Mineand Concentrators has progressed substantially. A revised action plan for the authorisation of<strong>waste</strong> sites, has been developed Table 8.Table 8. Mogalakwena Mine Revised Action Plan, May 2011.MOGALAKWENA : REVISED ACTION PLAN MAY 2011Activities Who? When?The existing landfill was licensed by the Department of Water Affairsand Forestry. It is nearing the designed maximum capacity. A landfillclosure plan is on hand, but a formal closure assessment must becompleted and submitted to DWA, when the Mine takes a decision toclose the area.ECWhen necessary.On closure, the landfill must be rehabilitated.A new landfill site has been identified. The site has been registeredwith LEDET and a Basic Assessment has been conducted. The EIAprocedure must be completed.• The Basic Assessment must still be submitted to LEDET.• Public Consultation Process.• Completion of a full EIA.• An authorisation through a Record of Decision from LEDETmust be obtained.• The landfill must be developed and commissioned.Five non hazardous salvage and <strong>waste</strong> transfer areas have beenidentified between the North and South Concentrators, that exceedthe threshold limit and which require an EIA.• A consultant must be appointed to conduct a joint EIA for the 5sites.• Completion of the EIA process.• An authorisation through a Record of Decision from LEDETmust be obtained.Mine<strong>SRK</strong><strong>SRK</strong><strong>SRK</strong>LEDETMineConcentrators.Consultant.LEDETJune 2011July 2011Dec 201120122012June 20112012201218

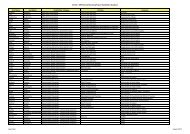

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________5. WASTE MINIMISATION, RE-USE & RECYCLING; AND TARGETSTarget:We will strive to reduce the quantities of <strong>waste</strong> disposed of, in our landfill by 15% (2008baseline) by 2014. Hence, we aim to reduce quantities of <strong>waste</strong> disposed to landfill by 2.5%a year. To achieve the latter target, <strong>waste</strong> minimization will be included in the scope of worksfor all our <strong>waste</strong> management contractors as a key performance indicator.Projects will focus on further increasing re-use and recycling of <strong>waste</strong> streams to decreasethe volume of <strong>waste</strong> currently sent to landfill.Mogalakwena graph40001200000035001000000030002500800000020006000000150040000001000500200000002008 2009 2010 YTD201111-Jan 11-Feb 11-Mar 11-Apr 11-May 11-Jun 11-Jul 11-Aug 11-Sep 11-Oct 11-Nov 11-Dec0Waste recycled Waste to Landfill Tonnes Milled TargetCurrent 2010 data indicates that the general <strong>waste</strong> disposed to landfill increased by 15% ofthe total <strong>waste</strong> disposed as compared to 2009. The <strong>waste</strong> figures for 2008 were extraordinary due to the fact that the North Concentrator was being commissioned during thisperiod.Table 9.Anglo Waste Minimisation, Re-Use & Recycling Action Plan.ANGLO WASTE MINIMISATION, RE-USE & RECYCLING: TARGETS AND ACTION PLAN2011Activities Who? When?Investigate Projects to focus on further increasing re-use and Waste contractor Apr 2011recycling of <strong>waste</strong> streams to decrease the volume of <strong>waste</strong>currently sent to landfillSeparation at source is as means to both improve the quantity of Waste contractor Apr 2011recyclables, and reduce <strong>waste</strong> sent to landfillEducation and awareness of the benefits associated with recovery,EC Apr 2011re-use and recycling to ensure full participation in re-use andrecycling initiativesSupply chain to consider putting <strong>waste</strong> minimization clause in the Supply chain/EC Dec 2011current contract of the <strong>waste</strong> contractorSupply chain to incorporate <strong>waste</strong> reduction principles into thedesign and packaging of products from suppliers to contribute toSupply chain Dec 201119

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________<strong>waste</strong> minimizationSupply chain to request reduced weight and size reduction of Supply chain Dec 2011material where possible.Supply chain to request for cleaner production and technology to Supply chain Dec 2011reduce <strong>waste</strong> where possibleAbatement plan for Mogalakwena <strong>waste</strong> tyre stockpile to minimise EC –Mick Angliss Apr 2011<strong>waste</strong> stored on siteMonthly Monitor and reporting of <strong>waste</strong> target to management EC Monthly20

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________6. SAWIS REPORTINGTable 10. SAWIS Reporting Action Plan 2011SAWIS REPORTING ACTION PLAN 2011Activities Who? When?All <strong>waste</strong> collected for disposal shall be quantified for reporting Contractor Apr 2011purposes.The <strong>waste</strong> quantity removed from the site will be recorded according Contractor Apr 2011to the different <strong>waste</strong> categories.These quantities will be reported in the monthly SHE database Site ECs OngoingTo ensure cradle to crave principle Landfill Inspections shall beEC Dec 2011conducted on all external sites to ensure responsible disposal atleast once in every two yearsTask procedures and policies should provide the foundation EC Apr 2011Reporting to SAWIS EC Whenrequired21

Mogalakwena <strong>waste</strong> <strong>strategy</strong> February 2011__________________________________________________________________________________7. WASTE TREATMENT AND DISPOSALSection.2 (a) (iv) of the Waste Act clearly indicates that the treatment and disposal of <strong>waste</strong> isa “last resort” within the hierarchy of <strong>waste</strong> management measures. In terms of <strong>waste</strong>treatment and processing, DEA supports the development of alternatives to landfill, includingincineration and gasification in so far as they generate energy.Table 11. Waste Treatment And Disposal Action Plan 2011WASTE TREATMENT AND DISPOSAL ACTION PLAN 2011Activities Who? When?Contract of the <strong>waste</strong> contractor to include legal requirements Supply chain/EC Dec 2011(regulations from NEMWA) regarding duties for collection andtransportationDraft appropriate operational standards for <strong>waste</strong> management,including monitoring and reporting requirements.EC/Contractor Dec 2011Investigate development of alternatives to landfill, including,pyrolosis treatment, incineration, and gasification in so far as theygenerate energyEC/EM:Mining Dec 201122