DESIGN NOTE

DESIGN NOTE

DESIGN NOTE

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

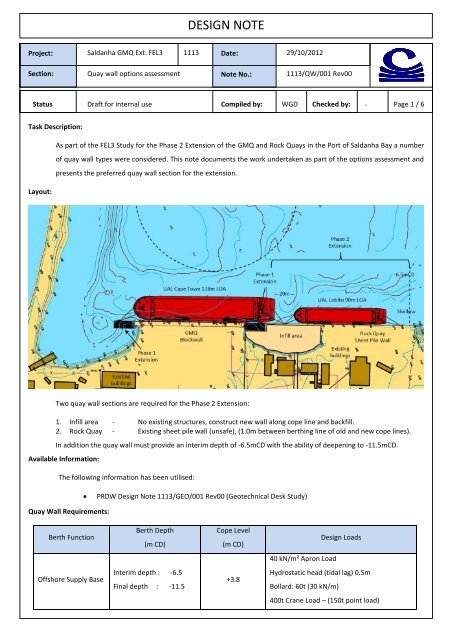

<strong>DESIGN</strong> <strong>NOTE</strong>Project:Saldanha GMQ Ext. FEL31113Date:29/10/2012Section:Quay wall options assessmentNote No.:1113/QW/001 Rev00Status Draft Compiled by: WGD Checked by: - Page 5 / 6knots3. Reinforced Concrete Counterfort WallAssessment CriteriaAbility to meetfunctional requirementsAvailability of skills:Availability of materials:CommentsMeets all requirementsSatisfactory –– Local concreting skills and marine placing skills for heavyprecast block are available – the availability of large heavy lift marine plant islimited.All materials can be locally procuredConstructabilityExtent of temporary works:Contractors site camp:Extensive – Reasonable sized casting yard, launching dockExtensive – Large footprint required mostly precast block stock pile, andspoil stock pile from the pla trench excavation.MaintainabilityRisk associated with unknownground conditions:Interaction with existing wallAccess for maintenance:Localisation and repairability ofdamage:Low – MPT is a counterfort structure - excavate material and extend stonebed if poor sub strata is encounteredExtensive – Requires complete removal of existing sheet pile wall at RockQuay as well as extensive excavation for the foundation trench - Tempsupport or removal of blocks required for tie in with existing blockwallEasy access to face of structureEasy to repair with FRP or concrete patch (joints require diver)Ease of Deepening From -6.5mCD to -11.5mCD Structure constructed at -11.5m CD – no interim optionCost and ValueConstructionprogrammeEnvironmental ImpactCapital Cost:Maintenance and OperationalCost:Duration:R 1 160 000/m (ROM -40 to +50% quay wall only construction cost, itemscommon to all walls types excluded i.e. quay furniture, paving, berth pocketdredging etc – Not to be used to calculate project costs - for comparisonpurposes only)Low – joint maintenance and Serviceability crack repairs to capping beam asrequired± 17 Months Average - Speed of construction is average – limited byproduction rate of casting yard, foundation trench construction and placingrate of marine plant –numerous interfaces between unit production, trenchexcavation, stone bed placing, unit placing, preloading and backfilling – Thesize of the units does have a positive impact on the placing speed.Significant – The construction of the foundation trench for the wall requiresthe removal of ± 60 000m³ of material, most of this this material will be stockpiled and reusedSEE FIGURE 5:The counterfort wall presents a more efficient concrete gravity option than the blockwall. However, TNPA have expressed concerns over thejoints in the counterforts at previous quay wall MCA meetings.This option also requires the full removal of the existing wall and extensive dredging to create the foundation trench. In addition the extensivetemporary works required for the unit construction of this quay type must be considered.This wall type has been successfully used in the Port of Saldanha at the MPT and has the advantage of Saldanha TNPA being familiar withoperational and maintenance requirements.

<strong>DESIGN</strong> <strong>NOTE</strong>Project:Saldanha GMQ Ext. FEL31113Date:29/10/2012Section:Quay wall options assessmentNote No.:1113/QW/001 Rev00Status Draft Compiled by: WGD Checked by: - Page 6 / 6knots4. Reinforced Concrete Deck with Steel Tubular Bearing PilesAssessment CriteriaAbility to meetfunctional requirementsCommentsHeavy lift loading on a deck structure is a concernAvailability of skills:Satisfactory – Local marine piling skills are availableConstructabilityMaintainabilityEase of DeepeningCost and ValueConstructionprogrammeEnvironmental ImpactAvailability of materials:Extent of temporary works:Contractors site camp:Risk associated with unknownground conditions:Interaction with existing wallAccess for maintenance:Localisation and repairability ofdamage:From -6.5mCD to -11.5mCDCapital Cost:Maintenance and OperationalCost:Duration:All materials can be locally procuredMinimal – Pile headstocks and deck support, casting yard for precast deckelementsMinimal – Small footprint required mostly pile stock pile, and spoil stock pilefrom existing sheet pile removalHigh – very hard layers and very soft layers pose potential design, cost andduration risks to a piling solutionExtensive – Requires complete removal of existing wall as well as extensiveexcavation for the revetment slope – Construction of a return wall requiredfor the tie in at the existing blockwall GMQEasy access to face of structure and deck top, limited access to underside ofdeckDeck easy to repair, damage to pile is much harderCutting slope and installing revetment after construction of the deck isdifficult therefore will construct to -11.5mCD atR 1 200 000/m (ROM -40 to +50% quay wall only construction cost, itemscommon to all walls types excluded i.e. quay furniture, paving, berth pocketdredging etc – Not to be used to calculate project costs - for comparisonpurposes only)Medium – Anode replacement, serviceability repairs to cracking deckconcrete, revetment maintenance± 22 Months Slow - Speed of construction is slow – with option foracceleration through the mobilisation of additional piling rigs (additionalcost) – Number of interfaces with excavation, pile driving, precast beam andpanel placing and insitu concreting of deckSignificant – Installation of the wall requires the removal and disposal of ±40 000m³ of material -- Revetment is a positiveSEE FIGURE 6:The deck on piles option provides an alternative to the material intensive gravity options. The piling risks associated with the sheet pile are stilla concern. However the use of steel tubular piles allows for grabbing out or chiselling through the tube to progress through the harder layers.This option also requires the full removal of the existing wall and extensive dredging to create the revetment slope.The heavy lift requirement for the deck structure results in heavy beams, a thick deck and a close pile spacing, which result in higherconstruction costs and a longer construction programme.

Precast cope panel – extended to -0.5m CD andgrout filled behind to protect against corrosionReinforced concrete capping beam+3.8mCDM100(500 MPa) 35m long0.0 mCDStone DrainBackfill SandFilter LayerAZ18 (350 MPa) Anchor Wall- Length of 7m - oversized due toincreased liquefaction risk in uppersoil strataQuarry RunInterim dredge depth -6.5mCDExisting materialDesign dredge depth -11.5mCDAZ46 (430 MPa)Main WallPotential Calcrete layers(50MPa)-24.0mCDMethod:1. Drive AZ46s2. Install AZ18 anchor wall3. Place to interim level - quarry run, filter layer and backfill material4. Install M76 tie rods5. Backfill anchor6. Tension tie rods7. Complete Back fill8. Install cope, services, paving and furnitureTitle:SALDANHA GMQ Ext. FEL3 STUDYFigure No.Steel Sheet Pile – Infill Section 2

Precast cope panel – extended to -0.5m CD andgrout filled behind to protect against corrosionReinforced concrete capping beam+3.8mCDBackfill SandM100 (500 MPa) 35m long0.0 mCDStone DrainExisting sheet pileExisting anchorAZ18 (350 MPa) Anchor Wall- Length of 7m - oversized due to increasedliquefaction risk in upper soil strataInterim dredge depth -6.5mCDExisting materialDesign dredge depth -11.5mCDAZ46 (430 MPa)Main Wall-24.0mCDPotential Calcrete layers(50MPa)Method:1. Drive AZ46s ahead of Rock Quay2. Excavate down to just above tie lvl of Rock Quay3. Cut existing Rock Quay sheet piles to just above tie lvl4. Install AZ18 anchor wall5. Install M100 tie rods6. Backfill anchor and gap between walls7. Tension tie rods8. Install cope, services, paving and furnitureTitle:SALDANHA GMQ Ext. FEL3 STUDYFigure No.Steel Sheet Pile – Rock Quay Section 3

Reinforced concrete capping beam+3.8m CD0.0m CDBackfill SANDInterim dredge depth -6.5mCDReinforced concrete counterfort unit(5m width)1:3Design dredge depth -11.5mCD1.0m thick stone bedTitle:SALDANHA GMQ Ext. FEL3 STUDYFigure No.Counterfort 5

Insitu reinforced concrete deckPrecast panels+3.8 mCD+0.0 mCDPrecast beamsReinforced concrete abutmentBackfill Sand1:1.5Quarry RunInterim dredge depth -6.5mCD1:3Design dredge depth -11.5mCDExisting materialØ800mm steel tubular piles-24.0mCDTitle:SALDANHA GMQ Ext. FEL3 STUDYFigure No.Deck-on-Piles 6

Title:SALDANHA GMQ Ext. FEL3 STUDYFigure No.MCA Results 7