DESIGN NOTE

DESIGN NOTE

DESIGN NOTE

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

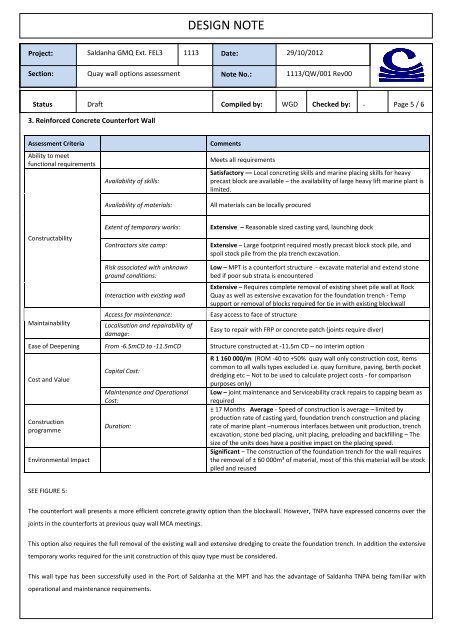

<strong>DESIGN</strong> <strong>NOTE</strong>Project:Saldanha GMQ Ext. FEL31113Date:29/10/2012Section:Quay wall options assessmentNote No.:1113/QW/001 Rev00Status Draft Compiled by: WGD Checked by: - Page 5 / 6knots3. Reinforced Concrete Counterfort WallAssessment CriteriaAbility to meetfunctional requirementsAvailability of skills:Availability of materials:CommentsMeets all requirementsSatisfactory –– Local concreting skills and marine placing skills for heavyprecast block are available – the availability of large heavy lift marine plant islimited.All materials can be locally procuredConstructabilityExtent of temporary works:Contractors site camp:Extensive – Reasonable sized casting yard, launching dockExtensive – Large footprint required mostly precast block stock pile, andspoil stock pile from the pla trench excavation.MaintainabilityRisk associated with unknownground conditions:Interaction with existing wallAccess for maintenance:Localisation and repairability ofdamage:Low – MPT is a counterfort structure - excavate material and extend stonebed if poor sub strata is encounteredExtensive – Requires complete removal of existing sheet pile wall at RockQuay as well as extensive excavation for the foundation trench - Tempsupport or removal of blocks required for tie in with existing blockwallEasy access to face of structureEasy to repair with FRP or concrete patch (joints require diver)Ease of Deepening From -6.5mCD to -11.5mCD Structure constructed at -11.5m CD – no interim optionCost and ValueConstructionprogrammeEnvironmental ImpactCapital Cost:Maintenance and OperationalCost:Duration:R 1 160 000/m (ROM -40 to +50% quay wall only construction cost, itemscommon to all walls types excluded i.e. quay furniture, paving, berth pocketdredging etc – Not to be used to calculate project costs - for comparisonpurposes only)Low – joint maintenance and Serviceability crack repairs to capping beam asrequired± 17 Months Average - Speed of construction is average – limited byproduction rate of casting yard, foundation trench construction and placingrate of marine plant –numerous interfaces between unit production, trenchexcavation, stone bed placing, unit placing, preloading and backfilling – Thesize of the units does have a positive impact on the placing speed.Significant – The construction of the foundation trench for the wall requiresthe removal of ± 60 000m³ of material, most of this this material will be stockpiled and reusedSEE FIGURE 5:The counterfort wall presents a more efficient concrete gravity option than the blockwall. However, TNPA have expressed concerns over thejoints in the counterforts at previous quay wall MCA meetings.This option also requires the full removal of the existing wall and extensive dredging to create the foundation trench. In addition the extensivetemporary works required for the unit construction of this quay type must be considered.This wall type has been successfully used in the Port of Saldanha at the MPT and has the advantage of Saldanha TNPA being familiar withoperational and maintenance requirements.