HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

center of gravity and create fast, light but long projectiles. In short, just<br />

about anything that can be launched from a small arm, be it airgun, shotgun,<br />

rifle or pistol, and some kinds of machine guns and cannons, can be<br />

swaged and is considered a bullet.<br />

<strong>Bullet</strong> swaging (SWAY-jing, sounds like “paging”) is the process of applying<br />

extremely high pressures (from 15,000 PSI for soft, unjacketed<br />

bullets to as high as 150,000 PSI for solid copper bullets) to materials<br />

contained in a very tough, extremely well finished die, so that the material<br />

will flow at room temperature and take on the shape of the die and the<br />

ends of the punches.<br />

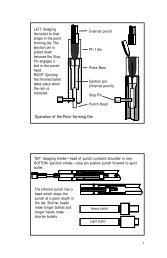

A die is a vessel to hold the pressure. A punch is a rod that fits into the<br />

hole in the die and seals off the end. If you refer to a punch as a die and<br />

vice versa, you may cause some interesting errors when placing orders.<br />

One of the first things to learn is the right names for the basic parts involved<br />

in the swaging process. You wouldn’t call a pistol a shotgun, would<br />

you? Probably not, or else you might get some odd-looking mail-order<br />

holsters!<br />

A business that is good at making swage dies probably will be buried<br />

in orders, with long waiting lists. Waiting up to a year to get your “die”<br />

and finding out everyone thought you wanted the “punch” that you asked<br />

for may be frustrating. Use the right terms and avoid this problem.<br />

In swaging bullets, you will always be putting a smaller diameter object<br />

(lead, jacket, or a combination of both) into a slightly larger die cavity<br />

or hole. Each step in swaging increases the diameter of the components,<br />

until they reach the final diameter in the last die. <strong>Swaging</strong> never<br />

reduces the diameter. You will only have stuck bullets and hard ejection if<br />

you try to push a slightly larger part into a slightly smaller hole. This is<br />

the difference between swaging and drawing. You never swage anything<br />

“down”. You never draw anything “up”.<br />

In drawing, you do push a larger part through a smaller hole, to reduce<br />

the diameter. This kind of die is a ring, not a cylinder closed on one<br />

end. The jacket or bullet that you are reducing is pushed through the ring,<br />

and is decreased in diameter when it comes through the other side.<br />

We use drawing to make longer, smaller caliber jackets from shorter,<br />

larger diameter ones. Also, within some narrow limits, it is possible to<br />

make a smaller caliber bullet from a larger one, although this degrades the<br />

quality of the bullet unless special conditions are observed. Usually the<br />

difference in diameters has to be within 0.006 thousandths of an inch<br />

when you reduce finished bullets by drawing. Jackets can be drawn much<br />

more than this, usually up to 30% smaller in one draw.<br />

11