HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Usually, the design of a swaging press gives you a big advantage in<br />

speed, accuracy, and safety over using other kinds of presses. After all, a<br />

pants press, a wine press, a full court press, and a printing press all are<br />

variations on the term “press”, and they are not suitable for reloading.<br />

Having said this, it is still possible to have custom dies built for just about<br />

any press you own. Just bear in mind that there is time involved in making<br />

working drawings, checking the stroke and ejection position, getting<br />

special thread taps and dies (sometimes), setting up the tooling for a onetime<br />

job, and other costs that have long been amortized over thousands<br />

of dies when you choose a standard production design instead.<br />

Besides, we may have spent a couple of decades and tens of thousands<br />

of dollars in testing and improving our standard tools and presses.<br />

Building something for the first time in a different design often requires<br />

some investment in development, which may be a waste of your money<br />

if we’ve already done it a thousand times before in a different and better<br />

system, which would be yours if you just got the right platform to run it<br />

(the proper press). With a different, special tool, you get to pay for any<br />

unforseen development requirements. With our own products, we already<br />

paid for development and you get to benefit from that. It’s usually a better<br />

deal.<br />

<strong>Swaging</strong> Principles<br />

1. Always swage “up”, never “down”. <strong>Swaging</strong> down is a contradiction.<br />

You “draw” down, by pushing something through an open ended<br />

ring die, like our JRD-1 jacket drawing die, or BRD-1 bullet reducing die.<br />

Drawing makes the part smaller in diameter and longer. It can also cause<br />

separation of the core and jacket if done to excess. <strong>Swaging</strong> makes the<br />

part shorter and larger, and tightens the grip of the jacket on the core.<br />

2. Pay attention to the instructions. If there are special written notes<br />

with your die, they are important because they modify or improve the<br />

general instructions and replace them. If there is a difference between<br />

specific notes sent with your set of dies, and anything published in general<br />

(as in this book or in general printed literature), follow the special<br />

written instructions in any respect where they may differ. <strong>Swaging</strong> is partly<br />

an art, and various materials or sizes may react differently to the same<br />

general kind of operations.<br />

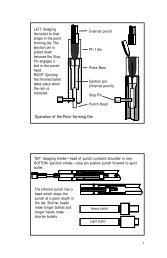

3. Use the right terminology! I cannot stress enough how important it<br />

can be to read what you have before you start to use it, and order the right<br />

part numbers and names of parts. People call the external punch everything<br />

from a “pin” to a “ram” to a “die” to a “die punch”. How are we<br />

supposed to know what you mean? If you order it wrong, you get to pay<br />

23