HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Gatling or 4-bore (.998) bullets can be made with 1-inch tubing. We do<br />

not stock these larger sizes but by the time the dies are ready, we would<br />

have a special order ready for you.<br />

For big game hunting, the tubing jacket may have the edge since it is<br />

easier to build thicker walled, tougher jackets with tubing (after all, the<br />

deep drawing operation is done for you in tubing and all you have to do is<br />

round over one end and adjust the diameter in a draw die). Jacket drawing<br />

from strip can be done easily in a hand press only for the shorter jacket<br />

lengths, because punching out a disk and turning it into a cup requires a<br />

lot of power early in the stroke. Hand presses generate almost all their<br />

power at the end of the stroke. Hydraulic presses are used for rifle jacket<br />

lengths, in order to get full power at the start of the stroke.<br />

Copper Tubing Jacket Maker Sets (CTJM-1-S, and -H)<br />

You can make jackets from copper tubing (or almost any other metal,<br />

but copper, aluminum, brass, and mild steel are the most practical things<br />

to use, and of these, copper works best for most shooting needs). To do<br />

this, you could use copper water tubing (yes, the same kind used to hook<br />

up wash basins), boiler tubing, or refrigeration tubing. <strong>Corbin</strong> has precision<br />

drawing grade tubing available also, if you want “good stuff” for<br />

testing.<br />

The cost of new tubing generally means that you won’t save money<br />

over buying jackets if the jacket you want is already available on the<br />

market. But most large caliber jackets for rifles, or heavy walled jackets of<br />

any sort, are simply not available unless you make them, so the cost of<br />

the jacket is secondary to whether or not you want a better bullet! If you<br />

can get a reasonably good quality surplus tubing from contractors or plumbers,<br />

and the wall thickness variation is not too great, construction sites<br />

and contractors might be a low-cost source.<br />

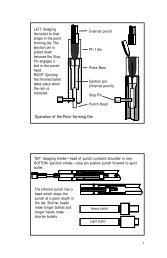

Regardless of the size or type, you would cut the tubing to length,<br />

deburr one end, put the piece over a precision punch and round the end<br />

over in the proper diameter end-rounding die (looks like a blunt point<br />

forming die), anneal the tube, draw it to smaller diameter, and then flatten<br />

the end with a special punch in your normal core seat die. All the tools<br />

you need to form the cut tubing pieces are included in the CTJM-1 tubing<br />

jacket maker, with the exception of the tubing saw to cut the tubing to<br />

length, and the proper core seating die to flatten the end of the tubing (or<br />

to form the boattail base). The core seating die (or boattail base former<br />

die) is part of the bullet swage set, so it is normally assumed that you<br />

have this die already.<br />

49