HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

HB-9 updated text (PDF) - Corbin Bullet Swaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

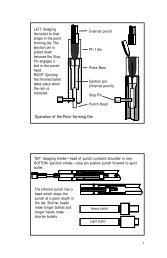

Dies Classified by Press Type<br />

We’ve talked about the basic design of bullet swage dies, in regard to<br />

their function. There is another category for classification of swage dies,<br />

and that is by the kind of press used to operate them. <strong>Swaging</strong> dies can be<br />

designed to operate in a reloading press (with severe limitations on pressure<br />

and precision), or in a number of different models of bullet swaging<br />

presses, both hand and hydraulic-electric powered.<br />

Years ago, we worked out a system of making standard parts for dies<br />

that would cover a wide range of calibers, and thus cut the cost of swaging<br />

through efficient use of what I call “semi-custom production”. We designed<br />

presses and die sets so that we could build similar punch and die<br />

blanks for certain ranges of calibers and bullet lengths, and then choose<br />

among perhaps three die body lengths for every caliber from .12 to .458<br />

in the hand presses, or from .224 to .998-in the dies for our big hydraulic<br />

presses.<br />

We didn’t have to design and build each die from scratch, because we<br />

built a standardized system for determining the minimum requirements<br />

of strength, die length, stroke length, punch geometry and strength, steels<br />

and heat treatment. We could run hundreds of blanks for each of the<br />

various presses, then hand-finish the cavities and hone the rough-finished<br />

punch blanks to a perfect fit during the custom phase of each order. It<br />

combined the economy of mass production with the flexibility and precision<br />

of custom tooling.<br />

<strong>Corbin</strong> swaging dies are up to ten times less costly than competitive<br />

dies without any sacrifice in precision because of this semi-custom production<br />

technique, and the fact that we design and build several different<br />

presses to take full advantage of the kind of operations you might want to<br />

undertake.<br />

The classification by press type also defines the die thread and diameter.<br />

The last letter in the catalog number identifies this classification.<br />

Dies with a catalog number ending in -R (such as the PRO-1-R) fit a<br />

standard 7/8-14 thread reloading press with an RCBS-type button shell<br />

holder ram. The die screws into the press head like a reloading die. The<br />

external punch slips into the T-slot of the ram. You do not also use a shell<br />

holder, since the punch base is made to simulate one.<br />

Dies with a catalog number ending in -M fit either the discontinued<br />

Silver Press, or the current S-Press. They are being phased out of stocking<br />

status in favor of the -S dies, which are larger and stronger, and fit the<br />

current S-Press or its predecessor, the Series II press (discontinued). However,<br />

we will continue to make them on special order, just not as a stock<br />

item. The -M dies have a 3/4-inch diameter main body, a thrust-adsorbing<br />

21