Click here to view as PDF - MICROmanufacturing

Click here to view as PDF - MICROmanufacturing

Click here to view as PDF - MICROmanufacturing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LASERpoints<br />

Fiducials: how <strong>to</strong> be w<strong>here</strong> you need <strong>to</strong> be<br />

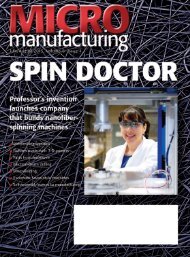

Panel Fiducial<br />

Global Fiducial<br />

14 | MARCH/APRIL 2010 | <strong>MICROmanufacturing</strong><br />

When running a job on a l<strong>as</strong>er—or any<br />

other <strong>to</strong>ol—it is frequently required<br />

that the processing <strong>to</strong>olpath be aligned <strong>to</strong> existing<br />

features. Generally, the sharper and<br />

smaller the alignment feature the more accurate<br />

the alignment.<br />

A camera- or optical-b<strong>as</strong>ed vision system<br />

usually is used. The alignment process can be<br />

performed manually or au<strong>to</strong>matically. Accuracies<br />

on the order of microns are possible with<br />

systems that incorporate high-resolution motion<br />

stages and camer<strong>as</strong>, and crisp fiducials.<br />

A fiducial, or fiduciary marker, is an object<br />

in an imaging system’s field of <strong>view</strong> that appears<br />

in the image produced and serves <strong>as</strong> a<br />

point of reference or a me<strong>as</strong>ure. One fiducial<br />

is usually designated “primary” and is used <strong>to</strong><br />

adjust the X/Y offset. Secondary fiducials are<br />

used for other operations. Fiducials are not all<br />

All images: Pho<strong>to</strong>Machining<br />

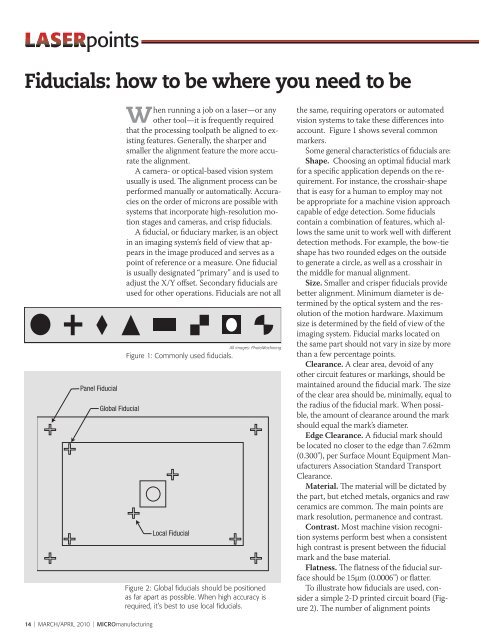

Figure 1: Commonly used fiducials.<br />

Local Fiducial<br />

Figure 2: Global fiducials should be positioned<br />

<strong>as</strong> far apart <strong>as</strong> possible. When high accuracy is<br />

required, it’s best <strong>to</strong> use local fiducials.<br />

the same, requiring opera<strong>to</strong>rs or au<strong>to</strong>mated<br />

vision systems <strong>to</strong> take these differences in<strong>to</strong><br />

account. Figure 1 shows several common<br />

markers.<br />

Some general characteristics of fiducials are:<br />

Shape. Choosing an optimal fiducial mark<br />

for a specific application depends on the requirement.<br />

For instance, the crosshair-shape<br />

that is e<strong>as</strong>y for a human <strong>to</strong> employ may not<br />

be appropriate for a machine vision approach<br />

capable of edge detection. Some fiducials<br />

contain a combination of features, which allows<br />

the same unit <strong>to</strong> work well with different<br />

detection methods. For example, the bow-tie<br />

shape h<strong>as</strong> two rounded edges on the outside<br />

<strong>to</strong> generate a circle, <strong>as</strong> well <strong>as</strong> a crosshair in<br />

the middle for manual alignment.<br />

Size. Smaller and crisper fiducials provide<br />

better alignment. Minimum diameter is determined<br />

by the optical system and the resolution<br />

of the motion hardware. Maximum<br />

size is determined by the field of <strong>view</strong> of the<br />

imaging system. Fiducial marks located on<br />

the same part should not vary in size by more<br />

than a few percentage points.<br />

Clearance. A clear area, devoid of any<br />

other circuit features or markings, should be<br />

maintained around the fiducial mark. The size<br />

of the clear area should be, minimally, equal <strong>to</strong><br />

the radius of the fiducial mark. When possible,<br />

the amount of clearance around the mark<br />

should equal the mark’s diameter.<br />

Edge Clearance. A fiducial mark should<br />

be located no closer <strong>to</strong> the edge than 7.62mm<br />

(0.300"), per Surface Mount Equipment Manufacturers<br />

Association Standard Transport<br />

Clearance.<br />

Material. The material will be dictated by<br />

the part, but etched metals, organics and raw<br />

ceramics are common. The main points are<br />

mark resolution, permanence and contr<strong>as</strong>t.<br />

Contr<strong>as</strong>t. Most machine vision recognition<br />

systems perform best when a consistent<br />

high contr<strong>as</strong>t is present between the fiducial<br />

mark and the b<strong>as</strong>e material.<br />

Flatness. The flatness of the fiducial surface<br />

should be 15μm (0.0006") or flatter.<br />

To illustrate how fiducials are used, consider<br />

a simple 2-D printed circuit board (Figure<br />

2). The number of alignment points