Click here to view as PDF - MICROmanufacturing

Click here to view as PDF - MICROmanufacturing

Click here to view as PDF - MICROmanufacturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

By Ronald D. Schaeffer,<br />

Pho<strong>to</strong>Machining Inc.<br />

defined in the <strong>to</strong>olpath determines the<br />

accuracy level <strong>to</strong> which a PCB panel<br />

can be aligned. The global alignment<br />

features should be placed <strong>as</strong> far apart <strong>as</strong><br />

possible for the best results and, in all<br />

c<strong>as</strong>es, should be sited outside the l<strong>as</strong>er<br />

processing area.<br />

If specific panel components require<br />

high processing accuracy, it may be best<br />

<strong>to</strong> use more local fiducials. However,<br />

this also incre<strong>as</strong>es cycle time, <strong>as</strong> t<strong>here</strong><br />

are more alignments per panel.<br />

One of four possible levels of alignment<br />

could be used. One-point alignment<br />

corrects an X/Y offset between an<br />

alignment point on the panel and the<br />

reference point in the file.<br />

<strong>as</strong> a linear function of X.<br />

For products that tend <strong>to</strong> dis<strong>to</strong>rt during<br />

the manufacturing process, such <strong>as</strong><br />

PCBs, three- or four-point alignment<br />

is commonly needed. For stable, rigid<br />

products made from metals, silicon,<br />

gl<strong>as</strong>s and ceramics, one- or two-point<br />

alignment generally suffices.<br />

For a manual-alignment procedure,<br />

continued on page 45<br />

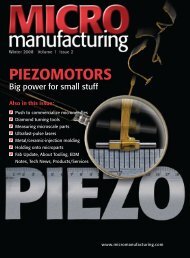

Someone challenged us<br />

<strong>to</strong> a little game of chess.<br />

(We chose 1:48 scale.)<br />

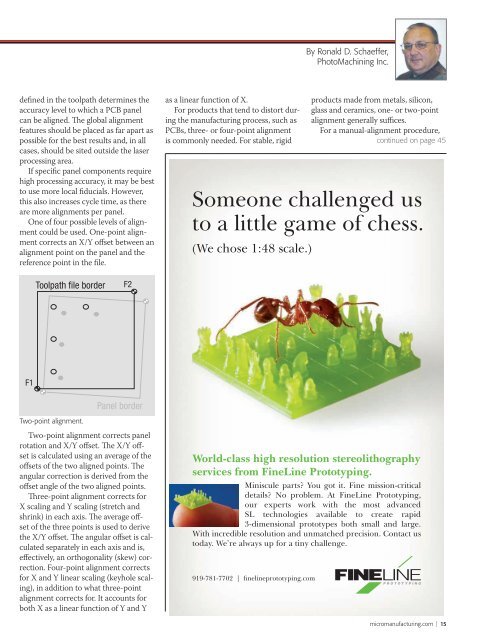

Toolpath file border<br />

F2<br />

F1<br />

Panel border<br />

Two-point alignment.<br />

Two-point alignment corrects panel<br />

rotation and X/Y offset. The X/Y offset<br />

is calculated using an average of the<br />

offsets of the two aligned points. The<br />

angular correction is derived from the<br />

offset angle of the two aligned points.<br />

Three-point alignment corrects for<br />

X scaling and Y scaling (stretch and<br />

shrink) in each axis. The average offset<br />

of the three points is used <strong>to</strong> derive<br />

the X/Y offset. The angular offset is calculated<br />

separately in each axis and is,<br />

effectively, an orthogonality (skew) correction.<br />

Four-point alignment corrects<br />

for X and Y linear scaling (keyhole scaling),<br />

in addition <strong>to</strong> what three-point<br />

alignment corrects for. It accounts for<br />

both X <strong>as</strong> a linear function of Y and Y<br />

World-cl<strong>as</strong>s high resolution stereolithography<br />

services from FineLine Pro<strong>to</strong>typing.<br />

Miniscule parts? You got it. Fine mission-critical<br />

details? No problem. At FineLine Pro<strong>to</strong>typing,<br />

our experts work with the most advanced<br />

SL technologies available <strong>to</strong> create rapid<br />

3-dimensional pro<strong>to</strong>types both small and large.<br />

With incredible resolution and unmatched precision. Contact us<br />

<strong>to</strong>day. We’re always up for a tiny challenge.<br />

919-781-7702 | finelinepro<strong>to</strong>typing.com<br />

micromanufacturing.com | 15