njit-etd2000-029 - New Jersey Institute of Technology

njit-etd2000-029 - New Jersey Institute of Technology

njit-etd2000-029 - New Jersey Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

15<br />

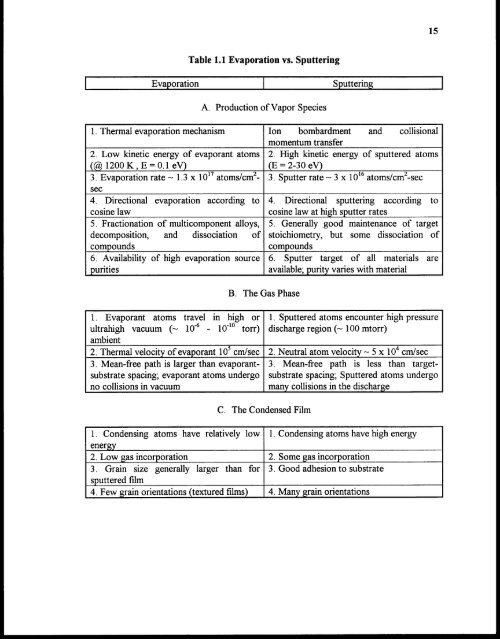

Table 1.1 Evaporation vs. Sputtering<br />

Evaporation Sputtering<br />

A. Production <strong>of</strong> Vapor Species<br />

1. Thermal evaporation mechanism Ion bombardment and collisional<br />

momentum transfer<br />

2. Low kinetic energy <strong>of</strong> evaporant atoms 2. High kinetic energy <strong>of</strong> sputtered atoms<br />

(@ 1200K , E = 0.1 eV)<br />

(E = 2-30 eV)<br />

3. Evaporation rate — 1.3 x 10 17 atoms/cm2- 3. Sputter rate ~ 3 x 10 16 atoms/cm2-sec<br />

sec<br />

4. Directional evaporation according to 4. Directional sputtering according to<br />

cosine law<br />

cosine law at high sputter rates<br />

5. Fractionation <strong>of</strong> multicomponent alloys, 5. Generally good maintenance <strong>of</strong> target<br />

decomposition, and dissociation <strong>of</strong> stoichiometry, but some dissociation <strong>of</strong><br />

compounds<br />

compounds<br />

6. Availability <strong>of</strong> high evaporation source<br />

purities<br />

1. Evaporant atoms travel in high or<br />

ultrahigh vacuum (~ 10-6 - 10-10 ton)<br />

ambient<br />

B. The Gas Phase<br />

6. Sputter target <strong>of</strong> all materials are<br />

available; purity varies with material<br />

1. Sputtered atoms encounter high pressure<br />

discharge region (~ 100 mtorr)<br />

2. Thermal velocity <strong>of</strong> evaporant 10 5 cm/sec 2. Neutral atom velocity ~ 5 x 104 cm/sec<br />

3. Mean-free path is larger than evaporantsubstrate<br />

spacing; evaporant atoms undergo substrate spacing; Sputtered atoms undergo<br />

3. Mean-free path is less than target-<br />

no collisions in vacuum<br />

many collisions in the discharge<br />

C. The Condensed Film<br />

1. Condensing atoms have relatively low 1. Condensing atoms have high energy<br />

energy<br />

2. Low gas incorporation 2. Some gas incorporation<br />

3. Grain size generally larger than for 3. Good adhesion to substrate<br />

sputtered film<br />

4. Few grain orientations (textured films) 4. Many grain orientations