View Full December PDF Issue - Utility Contractor Online

View Full December PDF Issue - Utility Contractor Online

View Full December PDF Issue - Utility Contractor Online

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

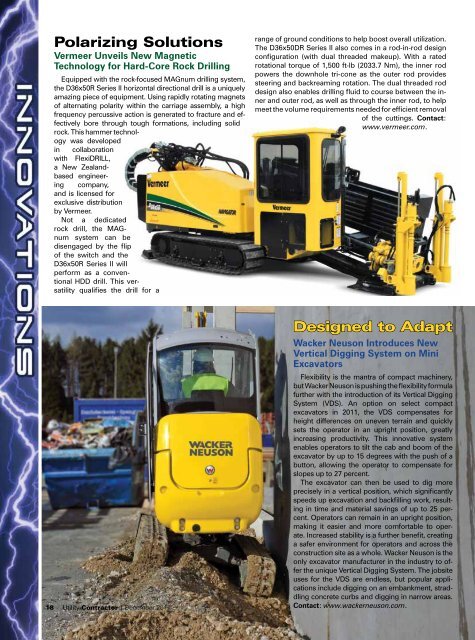

Polarizing Solutions<br />

Vermeer Unveils New Magnetic<br />

Technology for Hard-Core Rock Drilling<br />

Equipped with the rock-focused MAGnum drilling system,<br />

the D36x50R Series II horizontal directional drill is a uniquely<br />

amazing piece of equipment. Using rapidly rotating magnets<br />

of alternating polarity within the carriage assembly, a high<br />

frequency percussive action is generated to fracture and effectively<br />

bore through tough formations, including solid<br />

rock. This hammer technology<br />

was developed<br />

in collaboration<br />

with FlexiDRILL,<br />

a New Zealandbased<br />

engineering<br />

company,<br />

and is licensed for<br />

exclusive distribution<br />

by Vermeer.<br />

Not a dedicated<br />

rock drill, the MAGnum<br />

system can be<br />

disengaged by the flip<br />

of the switch and the<br />

D36x50R Series II will<br />

perform as a conventional<br />

HDD drill. This versatility<br />

qualifies the drill for a<br />

range of ground conditions to help boost overall utilization.<br />

The D36x50DR Series II also comes in a rod-in-rod design<br />

configuration (with dual threaded makeup). With a rated<br />

rotational torque of 1,500 ft-lb (2033.7 Nm), the inner rod<br />

powers the downhole tri-cone as the outer rod provides<br />

steering and backreaming rotation. The dual threaded rod<br />

design also enables drilling fluid to course between the inner<br />

and outer rod, as well as through the inner rod, to help<br />

meet the volume requirements needed for efficient removal<br />

of the cuttings. Contact:<br />

www.vermeer.com.<br />

18 <strong>Utility</strong> <strong>Contractor</strong> | <strong>December</strong> 2011<br />

Designed to Adapt<br />

Wacker Neuson Introduces New<br />

Vertical Digging System on Mini<br />

Excavators<br />

Flexibility is the mantra of compact machinery,<br />

but Wacker Neuson is pushing the flexibility formula<br />

further with the introduction of its Vertical Digging<br />

System (VDS). An option on select compact<br />

excavators in 2011, the VDS compensates for<br />

height differences on uneven terrain and quickly<br />

sets the operator in an upright position, greatly<br />

increasing productivity. This innovative system<br />

enables operators to tilt the cab and boom of the<br />

excavator by up to 15 degrees with the push of a<br />

button, allowing the operator to compensate for<br />

slopes up to 27 percent.<br />

The excavator can then be used to dig more<br />

precisely in a vertical position, which significantly<br />

speeds up excavation and backfilling work, resulting<br />

in time and material savings of up to 25 percent.<br />

Operators can remain in an upright position,<br />

making it easier and more comfortable to operate.<br />

Increased stability is a further benefit, creating<br />

a safer environment for operators and across the<br />

construction site as a whole. Wacker Neuson is the<br />

only excavator manufacturer in the industry to offer<br />

the unique Vertical Digging System. The jobsite<br />

uses for the VDS are endless, but popular applications<br />

include digging on an embankment, straddling<br />

concrete curbs and digging in narrow areas.<br />

Contact: www.wackerneuson.com.