View Full December PDF Issue - Utility Contractor Online

View Full December PDF Issue - Utility Contractor Online

View Full December PDF Issue - Utility Contractor Online

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Then There<br />

Was Light<br />

<strong>Utility</strong> <strong>Contractor</strong>s Need Not<br />

Fear the Dim Prospect of Being<br />

Left in the Dark<br />

By Todd Razor<br />

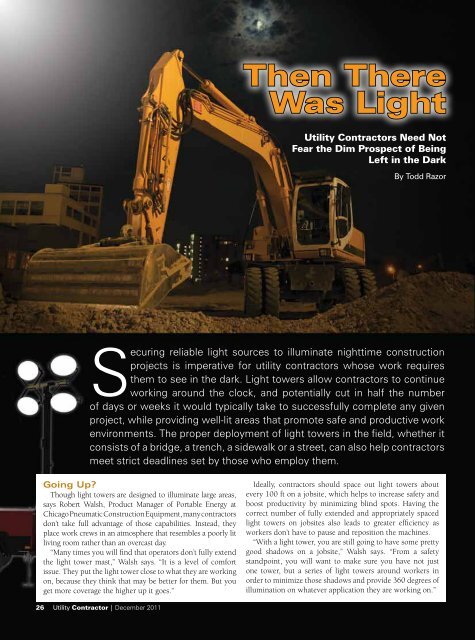

Securing reliable light sources to illuminate nighttime construction<br />

projects is imperative for utility contractors whose work requires<br />

them to see in the dark. Light towers allow contractors to continue<br />

working around the clock, and potentially cut in half the number<br />

of days or weeks it would typically take to successfully complete any given<br />

project, while providing well-lit areas that promote safe and productive work<br />

environments. The proper deployment of light towers in the field, whether it<br />

consists of a bridge, a trench, a sidewalk or a street, can also help contractors<br />

meet strict deadlines set by those who employ them.<br />

Going Up?<br />

Though light towers are designed to illuminate large areas,<br />

says Robert Walsh, Product Manager of Portable Energy at<br />

Chicago Pneumatic Construction Equipment, many contractors<br />

don’t take full advantage of those capabilities. Instead, they<br />

place work crews in an atmosphere that resembles a poorly lit<br />

living room rather than an overcast day.<br />

“Many times you will find that operators don’t fully extend<br />

the light tower mast,” Walsh says. “It is a level of comfort<br />

issue. They put the light tower close to what they are working<br />

on, because they think that may be better for them. But you<br />

get more coverage the higher up it goes.”<br />

Ideally, contractors should space out light towers about<br />

every 100 ft on a jobsite, which helps to increase safety and<br />

boost productivity by minimizing blind spots. Having the<br />

correct number of fully extended and appropriately spaced<br />

light towers on jobsites also leads to greater efficiency as<br />

workers don’t have to pause and reposition the machines.<br />

“With a light tower, you are still going to have some pretty<br />

good shadows on a jobsite,” Walsh says. “From a safety<br />

standpoint, you will want to make sure you have not just<br />

one tower, but a series of light towers around workers in<br />

order to minimize those shadows and provide 360 degrees of<br />

illumination on whatever application they are working on.”<br />

26 <strong>Utility</strong> <strong>Contractor</strong> | <strong>December</strong> 2011