STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

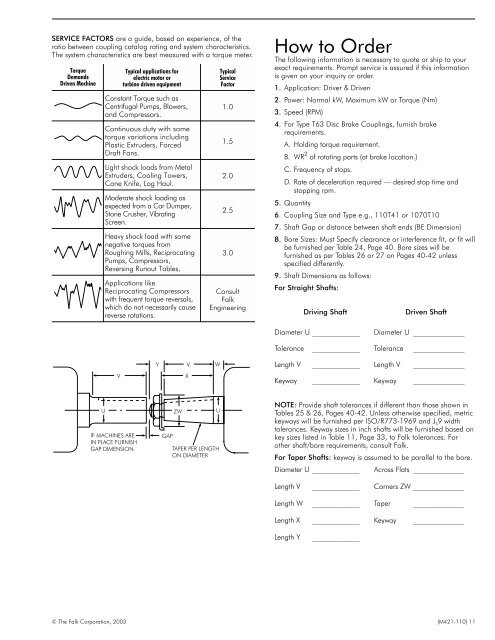

SERVICE FACTORS are a guide, based on experience, of the<br />

ratio between coupling catalog rating and system characteristics.<br />

The system characteristics are best measured with a torque meter.<br />

Torque<br />

Demands<br />

Driven Machine<br />

Typical applications for<br />

electric motor or<br />

turbine driven equipment<br />

Constant Torque such as<br />

Centrifugal Pumps, Blowers,<br />

and Compressors.<br />

Continuous duty with some<br />

torque variations including<br />

Plastic Extruders, Forced<br />

Draft Fans.<br />

Light shock loads from Metal<br />

Extruders, Cooling Towers,<br />

Cane Knife, Log Haul.<br />

Moderate shock loading as<br />

expected from a Car Dumper,<br />

Stone Crusher, Vibrating<br />

Screen.<br />

Heavy shock load with some<br />

negative torques from<br />

Roughing Mills, Reciprocating<br />

Pumps, Compressors,<br />

Reversing Runout Tables,<br />

Applications like<br />

Reciprocating Compressors<br />

with frequent torque reversals,<br />

which do not necessarily cause<br />

reverse rotations.<br />

Typical<br />

Service<br />

Factor<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

Consult<br />

Falk<br />

Engineering<br />

How to Order<br />

The following information is necessary to quote or ship to your<br />

exact requirements. Prompt service is assured if this information<br />

is given on your inquiry or order.<br />

1. Application: Driver & Driven<br />

2. Power: Normal kW, Maximum kW or Torque (Nm)<br />

3. Speed (RPM)<br />

4. For Type T63 Disc Brake Couplings, furnish brake<br />

requirements.<br />

A. Holding torque requirement.<br />

B. WR 2 of rotating parts (at brake location.)<br />

C. Frequency of stops.<br />

D. Rate of deceleration required — desired stop time and<br />

stopping rpm.<br />

5. Quantity<br />

6. Coupling Size and Type e.g., 110T41 or 1070T10<br />

7. Shaft Gap or distance between shaft ends (BE Dimension)<br />

8. Bore Sizes: Must Specify clearance or interference fit, or fit will<br />

be furnished per Table 24, Page 40. Bore sizes will be<br />

furnished as per Tables 26 or 27 on Pages 40-42 unless<br />

specified differently.<br />

9. Shaft Dimensions as follows:<br />

For Straight Shafts:<br />

Driving Shaft<br />

Driven Shaft<br />

Diameter U _____________<br />

Diameter U ______________<br />

Tolerance _____________ Tolerance ______________<br />

Y<br />

V<br />

W<br />

Length V _____________ Length V ______________<br />

V<br />

X<br />

Keyway _____________ Keyway ______________<br />

U<br />

IF MACHINES ARE<br />

IN PLACE FURNISH<br />

GAP DIMENSION.<br />

GAP<br />

ZW<br />

U<br />

TAPER PER LENGTH<br />

ON DIAMETER<br />

NOTE: Provide shaft tolerances if different than those shown in<br />

Tables 25 & 26, Pages 40-42. Unless otherwise specified, metric<br />

keyways will be furnished per ISO/R773-1969 and J S 9 width<br />

tolerances. Keyway sizes in inch shafts will be furnished based on<br />

key sizes listed in Table 11, Page 33, to Falk tolerances. For<br />

other shaft/bore requirements, consult Falk.<br />

For Taper Shafts: keyway is assumed to be parallel to the bore.<br />

Diameter U _____________ Across Flats ______________<br />

Length V _____________ Corners ZW ______________<br />

Length W _____________ Taper ______________<br />

Length X _____________ Keyway ______________<br />

Length Y<br />

_____________<br />

© The Falk Corporation, 2003 (M421-110) 11