STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

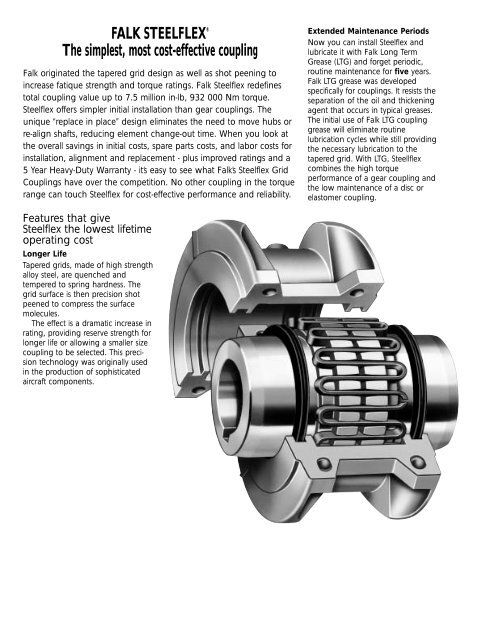

FALK STEELFLEX ®<br />

The simplest, most cost-effective coupling<br />

Falk originated the tapered grid design as well as shot peening to<br />

increase fatique strength and torque ratings. Falk Steelflex redefines<br />

total coupling value up to 7.5 million in-lb, 932 000 Nm torque.<br />

Steelflex offers simpler initial installation than gear couplings. The<br />

unique “replace in place” design eliminates the need to move hubs or<br />

re-align shafts, reducing element change-out time. When you look at<br />

the overall savings in initial costs, spare parts costs, and labor costs for<br />

installation, alignment and replacement - plus improved ratings and a<br />

5 Year Heavy-Duty Warranty - it’s easy to see what Falk’s Steelflex Grid<br />

Couplings have over the competition. No other coupling in the torque<br />

range can touch Steelflex for cost-effective performance and reliability.<br />

Extended Maintenance Periods<br />

Now you can install Steelflex and<br />

lubricate it with Falk Long Term<br />

Grease (LTG) and forget periodic,<br />

routine maintenance for five years.<br />

Falk LTG grease was developed<br />

specifically for couplings. It resists the<br />

separation of the oil and thickening<br />

agent that occurs in typical greases.<br />

The initial use of Falk LTG coupling<br />

grease will eliminate routine<br />

lubrication cycles while still providing<br />

the necessary lubrication to the<br />

tapered grid. With LTG, Steellflex<br />

combines the high torque<br />

performance of a gear coupling and<br />

the low maintenance of a disc or<br />

elastomer coupling.<br />

Features that give<br />

Steelflex the lowest lifetime<br />

operating cost<br />

Longer Life<br />

Tapered grids, made of high strength<br />

alloy steel, are quenched and<br />

tempered to spring hardness. The<br />

grid surface is then precision shot<br />

peened to compress the surface<br />

molecules.<br />

The effect is a dramatic increase in<br />

rating, providing reserve strength for<br />

longer life or allowing a smaller size<br />

coupling to be selected. This precision<br />

technology was originally used<br />

in the production of sophisticated<br />

aircraft components.