STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

STEELFLEX® - Rexnord

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

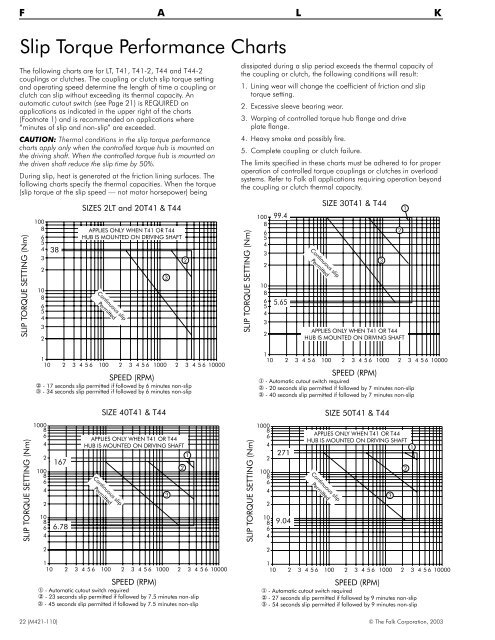

F A L K<br />

Slip Torque Performance Charts<br />

The following charts are for LT, T41, T41-2, T44 and T44-2<br />

couplings or clutches. The coupling or clutch slip torque setting<br />

and operating speed determine the length of time a coupling or<br />

clutch can slip without exceeding its thermal capacity. An<br />

automatic cutout switch (see Page 21) is REQUIRED on<br />

applications as indicated in the upper right of the charts<br />

(Footnote 1) and is recommended on applications where<br />

“minutes of slip and non-slip” are exceeded.<br />

CAUTION: Thermal conditions in the slip torque performance<br />

charts apply only when the controlled torque hub is mounted on<br />

the driving shaft. When the controlled torque hub is mounted on<br />

the driven shaft reduce the slip time by 50%.<br />

During slip, heat is generated at the friction lining surfaces. The<br />

following charts specify the thermal capacities. When the torque<br />

(slip torque at the slip speed — not motor horsepower) being<br />

SLIP TORQUE SETTING (Nm)<br />

100<br />

8<br />

6<br />

5<br />

4<br />

3<br />

2<br />

10<br />

8<br />

6<br />

5<br />

4<br />

3<br />

2<br />

38<br />

SIZES 2LT and 20T41 & T44<br />

APPLIES ONLY WHEN T41 OR T44<br />

HUB IS MOUNTED ON DRIVING SHAFT<br />

Continuous slip<br />

Permitted<br />

3<br />

2<br />

dissipated during a slip period exceeds the thermal capacity of<br />

the coupling or clutch, the following conditions will result:<br />

1. Lining wear will change the coefficient of friction and slip<br />

torque setting.<br />

2. Excessive sleeve bearing wear.<br />

3. Warping of controlled torque hub flange and drive<br />

plate flange.<br />

4. Heavy smoke and possibly fire.<br />

5. Complete coupling or clutch failure.<br />

The limits specified in these charts must be adhered to for proper<br />

operation of controlled torque couplings or clutches in overload<br />

systems. Refer to Falk all applications requiring operation beyond<br />

the coupling or clutch thermal capacity.<br />

SLIP TORQUE SETTING (Nm)<br />

100<br />

8<br />

6<br />

5<br />

4<br />

3<br />

2<br />

3<br />

2<br />

99.4<br />

10<br />

8<br />

6 5.65<br />

5<br />

4<br />

Continuous slip<br />

Permitted<br />

SIZE 30T41 & T44<br />

APPLIES ONLY WHEN T41 OR T44<br />

HUB IS MOUNTED ON DRIVING SHAFT<br />

3<br />

2<br />

1<br />

1<br />

10 2 3 4 5 6 100 2 3 4 5 6 1000 2 3 4 5 6 10000<br />

SPEED (RPM)<br />

- 17 seconds slip permitted if followed by 6 minutes non-slip<br />

- 34 seconds slip permitted if followed by 6 minutes non-slip<br />

1<br />

10 2 3 4 5 6 100 2 3 4 5 6 1000 2 3 4 5 6 10000<br />

SPEED (RPM)<br />

- Automatic cutout switch required<br />

- 20 seconds slip permitted if followed by 7 minutes non-slip<br />

- 40 seconds slip permitted if followed by 7 minutes non-slip<br />

SIZE 40T41 & T44<br />

SIZE 50T41 & T44<br />

SLIP TORQUE SETTING (Nm)<br />

1000<br />

8<br />

6<br />

4<br />

2<br />

100<br />

8<br />

6<br />

4<br />

2<br />

10<br />

8<br />

6<br />

4<br />

167<br />

6.78<br />

APPLIES ONLY WHEN T41 OR T44<br />

HUB IS MOUNTED ON DRIVING SHAFT<br />

1<br />

Continuous slip<br />

Permitted<br />

3<br />

2<br />

SLIP TORQUE SETTING (Nm)<br />

1000<br />

8<br />

6<br />

4<br />

2<br />

100<br />

8<br />

6<br />

4<br />

2<br />

10<br />

8<br />

6<br />

4<br />

271<br />

9.04<br />

APPLIES ONLY WHEN T41 OR T44<br />

HUB IS MOUNTED ON DRIVING SHAFT<br />

Continuous slip<br />

Permitted<br />

3<br />

2<br />

1<br />

2<br />

2<br />

1<br />

10 2 3 4 5 6 100 2 3 4 5 6 1000 2 3 4 5 6 10000<br />

SPEED (RPM)<br />

- Automatic cutout switch required<br />

- 23 seconds slip permitted if followed by 7.5 minutes non-slip<br />

- 45 seconds slip permitted if followed by 7.5 minutes non-slip<br />

1<br />

10 2 3 4 5 6 100 2 3 4 5 6 1000 2 3 4 5 6 10000<br />

SPEED (RPM)<br />

- Automatic cutout switch required<br />

- 27 seconds slip permitted if followed by 9 minutes non-slip<br />

- 54 seconds slip permitted if followed by 9 minutes non-slip<br />

22 (M421-110) © The Falk Corporation, 2003