K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

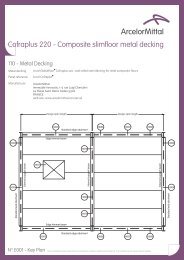

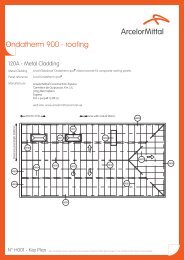

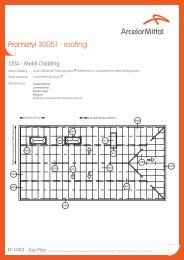

120A - Metal Cladding<br />

External facing material<br />

0.63mm or 0.75mm gauge galvanized cold rolled steel sheet<br />

grade S220 G to EN10326 & EN10346<br />

Finish/colour<br />

Internal facing material<br />

Finish/colour<br />

Colorissme range (we recommend using light colours) to EN10169<br />

0.5mm or 0.63mm gauge galvanized cold rolled steel sheet<br />

grade S220 G to EN10326 & EN10346<br />

Interior 912 to EN10169<br />

3<br />

Core insulation HCFC free rigid polyurethane foam, density 40kg/m giving i [W/(m.K)]<br />

on stated overall K.<strong>Energy</strong> thickness module:<br />

140mm - 0.37; 160mm - 0.28; 180mm - 0.23; 200mm - 0.19; 220mm - 0.17.<br />

Please contact our Technical Department for further information/individual project assessment<br />

1000 Cover width<br />

333.3mm<br />

Promisol 1001T vertically laid <strong>wall</strong> <strong>panel</strong><br />

Panel thickness<br />

Main <strong>panel</strong> fixing in accordance to the specification of <strong>panel</strong> thickness<br />

Horizontal steelwork sheeting rail<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

10mm minimum<br />

Side lap fixing screw at<br />

maximum 450mm centres<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

50<br />

6x5mm butyl rubber sealant (site applied)<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong><br />

200<br />

End lap stitcher screw at<br />

every crown<br />

End lap detail<br />

50<br />

10mm nominal 20mm maximum<br />

3 Rows of 6x5mm butyl rubber<br />

sealant (site applied)<br />

Main <strong>panel</strong> fixing screw as per<br />

job specific calculations<br />

Side lap detail<br />

6mm diameter butyl rubber sealant<br />

Vapour seal when required (site applied)<br />

Direction of lay<br />

N° K003 - Panel Arrangement (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)