K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

K.Energy insulated wall panel system - PGA Consultants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

K.<strong>Energy</strong> <strong>insulated</strong> <strong>wall</strong> <strong>panel</strong> <strong>system</strong><br />

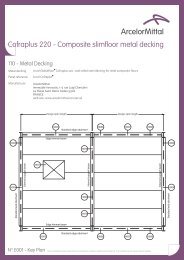

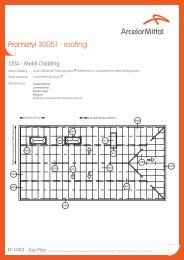

120A - Metal Cladding<br />

Primary cladding fasteners Self tapping and self drilling screws (galvanized carbon steel) .<br />

Number and location of<br />

fasteners<br />

Sealing Cladding<br />

550A Seals<br />

1 N° fastener at every support rail fixed through <strong>panel</strong> trough plus intermediate fasteners<br />

at 450mm centers or as required by project specific calculations.<br />

.<br />

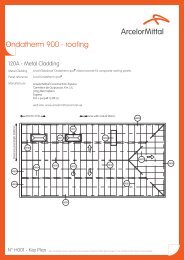

Horizontal - Rolled steel full interlocking male/female edges giving weather tight overlap joint.<br />

Vertical - Extended top profile with foam core and bottom profile cut back to give a fully sealed<br />

overlap joint (200mm) complete with 3 continuous rows of 6mm x 5mm butyl rubber sealant.<br />

554A Vapour seals<br />

Sealant tape: 20mm x 5mm closed cell foam vapour strip positioned in straight unbroken lines at <strong>panel</strong><br />

supports, parallel to and slightly back from end of <strong>panel</strong>. Do not allow tape to be stretched into position.<br />

Ensure continuity and effectiveness of seal, especially at sheet corners. Ensure adequate over-compression<br />

to achieve required vapour seal.<br />

Sealing of outer cladding <strong>system</strong> to be in accordance with NBS applicable to <strong>system</strong> selected<br />

Horizontal steelwork sheeting rail<br />

6mm diameter butyl rubber sealant<br />

Vapour seal when required (site applied)<br />

77 insulation<br />

zone<br />

6x5mm butyl rubber sealant (site applied)<br />

Promisol 1001T <strong>wall</strong> <strong>panel</strong> vertically laid<br />

43<br />

Panel thickness<br />

Ondafix vertical support rail<br />

Low profile colour coated fixing at 180 (or 360)<br />

centres to suit design applied loading<br />

Fixing at 450 centres<br />

Profiled foam fillers<br />

0.75mm thick closer feature fin<br />

Illustrative only - Frequence 5.180.43 B <strong>wall</strong> sheet horizontally laid<br />

May be replaced by any suitable external steel or aluminium profile,<br />

"hi-tec" <strong>panel</strong>ling, timber cladding or reconstituted stone<br />

Refer drawing K012 for the 4 No end lap options of the frequence 5.180.43 B <strong>wall</strong> sheet<br />

N° K004/2 - Sealing Joints 1 (Note: All installations should comply with the recommendations contained in MCRMA Techinical Papers N° 12 & 14; BS3200 and other relevant national standards)