You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TWO CELL END INLET COOLING TOWERS<br />

IDEAL <strong>REP</strong>LACEMENT FOR CROSSFLOW UNITS<br />

MODELS <strong>REP</strong> 217-111 TO <strong>REP</strong> 224-920 / 367-1600 NOMINAL TONS<br />

LOW INSTALLATION COSTS - CONTRACTOR SAVINGS<br />

The <strong>REP</strong>’s fit tight enclosures and match up with crossflow layouts, piping, and steel, while still offering<br />

the maintenance and operational advantages of EVAPCO’s induced draft counterflow cooling towers.<br />

Layout Savings<br />

The <strong>REP</strong> counterflow method of heat transfer is the most efficient in the industry, resulting in a plan area up to 35%<br />

less than a comparable sized crossflow tower. The <strong>REP</strong>’s smaller plan area enables it to be located in smaller, less<br />

costly enclosures.<br />

<strong>REP</strong> units draw air from all four sides, so it is ideal for tight replacement projects. The <strong>REP</strong> can be placed close to a<br />

surrounding wall with little or no effect on unit capacity. The <strong>REP</strong> ’s are ideal for matching existing crossflow layouts.<br />

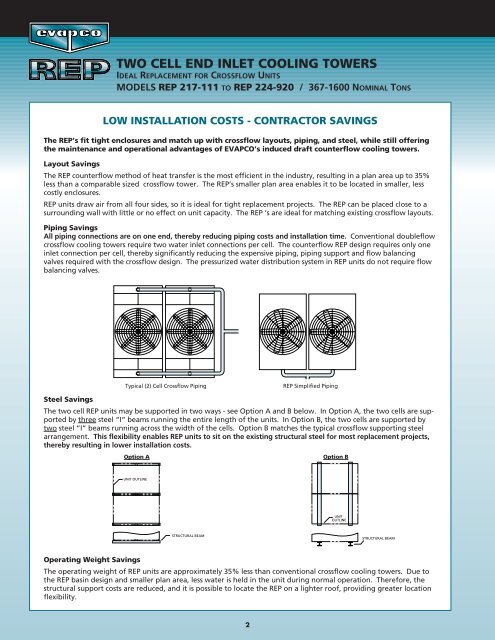

Piping Savings<br />

All piping connections are on one end, thereby reducing piping costs and installation time. Conventional doubleflow<br />

crossflow cooling towers require two water inlet connections per cell. The counterflow <strong>REP</strong> design requires only one<br />

inlet connection per cell, thereby significantly reducing the expensive piping, piping support and flow balancing<br />

valves required with the crossflow design. The pressurized water distribution system in <strong>REP</strong> units do not require flow<br />

balancing valves.<br />

Typical (2) Cell Crossflow Piping<br />

<strong>REP</strong> Simplified Piping<br />

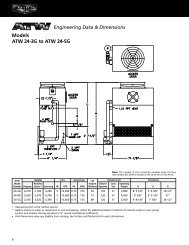

Steel Savings<br />

The two cell <strong>REP</strong> units may be supported in two ways - see Option A and B below. In Option A, the two cells are supported<br />

by three steel “I” beams running the entire length of the units. In Option B, the two cells are supported by<br />

two steel “I” beams running across the width of the cells. Option B matches the typical crossflow supporting steel<br />

arrangement. This flexibility enables <strong>REP</strong> units to sit on the existing structural steel for most replacement projects,<br />

thereby resulting in lower installation costs.<br />

Option A<br />

Option B<br />

UNIT OUTLINE<br />

UNIT<br />

OUTLINE<br />

STRUCTURAL BEAM<br />

STRUCTURAL BEAM<br />

Operating Weight Savings<br />

The operating weight of <strong>REP</strong> units are approximately 35% less than conventional crossflow cooling towers. Due to<br />

the <strong>REP</strong> basin design and smaller plan area, less water is held in the unit during normal operation. Therefore, the<br />

structural support costs are reduced, and it is possible to locate the <strong>REP</strong> on a lighter roof, providing greater location<br />

flexibility.<br />

2