Download Brochure (pdf) - Sampo-Rosenlew

Download Brochure (pdf) - Sampo-Rosenlew

Download Brochure (pdf) - Sampo-Rosenlew

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

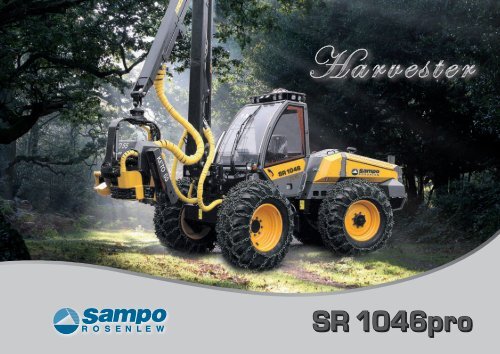

SR 1046pro

<strong>Sampo</strong> <strong>Rosenlew</strong> harvesters<br />

The 1046pro new features<br />

The electric system is now 24 V. The relay<br />

logic is replaced by a circuit board. The<br />

wire harnesses are simpler, and the wires in<br />

the most important accessories (e.g. Eberspächer)<br />

are joined to the harness.<br />

The main current switch is electric. The fuses<br />

are all in the same place in the cab, and two<br />

main current fuses are near the battery, which<br />

makes troubleshooting easier. The keyboard<br />

module of the harvesting computer is attached<br />

to the seat, which decreases the number<br />

of loose wires. Idling as well as the working and<br />

maximum revolutions of the engine can be selected<br />

quickly using the rocking switch. Settings<br />

are made through the Iqan. The vacuum<br />

pump can be quickly switched on in the cab using<br />

the ignition key, which means savings on oil<br />

leakages.<br />

The new generation Iqan system is used. The<br />

Iqan now has a colour display; separate<br />

meters are no longer needed. The base machine,<br />

the diesel engine and the harvester head<br />

can communicate with each other. The sensors<br />

are connected to the Iqan, so their status and possible<br />

errors can be seen on the display. Error<br />

signals from the engine and the base machine<br />

appear on the display in a text format in the<br />

chosen language.

The new Common Rail diesel engine has 84 kW on 2 200 rpm (89 kW on 2000 rpm). Torque is 500<br />

Nm on 1 500 rpm. There is more power and torque than before. The new radiator cells have an<br />

intercooler. The air filter of the engine is larger than before. The ejector is more efficient. There is an<br />

additional fuel transfer pump from the back to the front of the fuel tank as standard equipment.<br />

If stump spray is not needed, the fuel tank volume can be increased by 55 litres.<br />

Plenty of more<br />

•<br />

Another water circulation pump has been<br />

•<br />

The individual pressures of the harvesting<br />

added to engine heating to ensure the air<br />

head are set proportionally, which means<br />

pockets do not turn off the heating.<br />

fuel savings.<br />

•<br />

The flexible coupler between the pump<br />

•<br />

The “bye-bye” working lights light the sur-<br />

and the flywheel of the engine is now larg-<br />

roundings of the harvester for 1.5 minutes<br />

er, the same as on the 1066.<br />

after the main current has been switched<br />

off, if desired.<br />

•<br />

The turning angle of the middle joint has increased<br />

from 45 degrees to 50 degrees. With<br />

•<br />

The new Kesla H671 crane is 100 kg stronger<br />

500 mm tyres the outer radius of the turning<br />

than the H571. Lifting capacity is now 640<br />

circle is 4 m 2 cm. The diameters of the verti-<br />

kg. The working pressure decreased, which<br />

cal pins and the bearings of the middle joint<br />

also decreased the amount of wasted ener-<br />

have increased from 60 mm to 80 mm.<br />

gy in the joint use of the movements. Side<br />

supports and 14 bolts instead of 8 are used<br />

•<br />

The circulation pump of oil cooling has in-<br />

in the crane mounting.<br />

creased from 23cc to 33cc.<br />

SR 1046 Pro

Technical specification 1046pro<br />

Weight<br />

8, 000 - 9, 500 kg<br />

Engine SisuDiesel 44 CTA, 4 cylinders<br />

Output<br />

Fuel tank<br />

135 l<br />

Transmission Type Hydrostatic<br />

Turning radius<br />

4, 020 mm<br />

Wheels Front and rear 500/60-26.5<br />

Working hydraulics<br />

Working hydraulics<br />

pump<br />

Hydraulic oil tank<br />

600/55-26.5<br />

540/65-28<br />

650/60-26.5<br />

240 l/min @ 2, 200 rpm<br />

/ 210 bar<br />

115 l<br />

Eletric system Voltage 24 V<br />

Battery<br />

Charging generator<br />

2 • 115 Ah<br />

100 A<br />

Crane Reach 7.1 m<br />

Lifting moment, gross<br />

Turning moment<br />

55 kNm<br />

17 kNm<br />

Harvesting Head Keto 51 - 55<br />

Kesla 18 RH<br />

Nisula 400 H<br />

Max. delimbing Approximately 320 mm<br />

diameter<br />

Measuring device<br />

Motomit<br />

Brakes Properties Hydraulically / mechanically<br />

controlled disc -<br />

/ multi-disc brakes<br />

Cab<br />

Windows<br />

Quiet safety cab<br />

(FOPS, ROPS, OPS)<br />

12 mm polycarbonate<br />

The manufacturer reserves the right to make changes to the machines without notice and without<br />

obligation to make such changes to machines manufactured before. Specifications may<br />

vary from country to country. Contact your retailer for current specifications.<br />

<strong>Sampo</strong> <strong>Rosenlew</strong> Ltd - Konepajanranta 2 A - PL 50 - 28101 PORI - Tel.: +358 207 550 555 - Fax: +358 2 632 6546 - www.sampo-rosenlew.fi