Download - Harting

Download - Harting

Download - Harting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

without compromising the overall safety,<br />

reliability and flexibility of the system.<br />

The Czech company TENAX CZ s.r.o. worked<br />

closely with HARTING to develop a highperformance<br />

system which offers a complete<br />

range of functions and can be adapted to<br />

the needs of the particular application. A<br />

safe, simple user interface was also a major<br />

design goal.<br />

A functional block design that can be tailored<br />

to individual customer needs was chosen<br />

to meet these requirements. The company<br />

can provide systems with automatic control,<br />

semi-automatic control or full manual<br />

control. Modularity is a key feature of the<br />

mechanical design as well. All of the mechanical parts<br />

are prefabricated, and they can be assembled to make a<br />

building-block kit which is easy to erect and take down<br />

again. All of the elements are designed to withstand harsh<br />

climatic conditions and high mechanical stress (IP 65, antivandalism).<br />

At the push of a button<br />

Construction workers can operate the TENAX system directly<br />

in automatic mode. The cabin can be positioned to the desired<br />

floor by pressing a button on call boxes which are located<br />

on each floor. The destination floor can be selected from<br />

Fig. 1: Control box on the new<br />

top floor<br />

Fig. 2: Floor control boxes prepared for floor extension<br />

the panel keyboard in the cabin. Indicator lights or text on<br />

the display panel keep the operator informed about current<br />

instructions and all major system status conditions.<br />

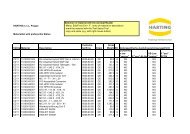

A floor control box (PO), which can be used to request the<br />

cabin, is located on each floor. The control boxes on the floors<br />

have connectors where prefabricated cables are attached.<br />

nth floor control<br />

box<br />

termination<br />

panel<br />

SPO<br />

drives PLC K exciter circuit<br />

2nd floor control<br />

box<br />

1st floor control<br />

box<br />

TNX<br />

PLC S<br />

PLC K<br />

TNX<br />

SPO<br />

stable control unit<br />

control unit mounted in the cabin<br />

TNX bus<br />

floor control bus<br />

exciter circuit<br />

PLC S<br />

Fig. 3: Control system for special-purpose elevators<br />

3<br />

73