Svetsaren_nr2 definitief (Page 1) - Esab

Svetsaren_nr2 definitief (Page 1) - Esab

Svetsaren_nr2 definitief (Page 1) - Esab

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

are being secured from Western Europe, the Far East<br />

and the USA, as a result of growing international<br />

recognition. CIMTAS now constructs regularly for<br />

clients such as Bechtel, Framatome-Proser, MHI, GE,<br />

Cargill, NEM, CMI, UOP (Europe), GE Hydro, FWI,<br />

KTI, Technip, KBR, BP, BASF, UOP(USA), Nuovo<br />

Pignone. Quality, in-time delivery and customer<br />

satisfaction are central elements in the company<br />

philosophy, whereas internally a zero accident target<br />

and an environmental protection plan are given high<br />

priority using a consistent awareness campaign.<br />

ESAB and CIMTAS<br />

Serving a dynamic fabricator such as CIMTAS calls for<br />

the availability of a contact person and nearby stock. The<br />

day-to-day business with CIMTAS is handled by ESAB’s<br />

local dealer Özmetal, which is located in Istanbul and<br />

houses a substantial stock of consumables, equipment<br />

and spare parts. However, when new solutions are<br />

needed, ESAB’s representative office acts as an<br />

intermediary between CIMTAS and the many resources<br />

of ESAB worldwide, based on an understanding of the<br />

client’s business and needs. In recent years, this has<br />

resulted in a mutually satisfactory partnership with<br />

knowledge sharing, many improvements and steadily<br />

increasing welding and cutting productivity.<br />

The organisation of welding<br />

The Gemlik works employs around 240 welders and<br />

three EWEs. Welder education, certification and<br />

project training are done internally at the CIMTAS<br />

Training Centre, which is well equipped with a<br />

representation of the 110 MIG/MAG power sources, 26<br />

single-wire and tandem SAW installations, 70 SMAW<br />

units and 150 TIG machines which are used in the<br />

workshops. The company has access to its own<br />

metallographic and mechanical laboratory.<br />

Apart from windmill towers, the mainstream of projects<br />

at the Gemlik works comprises heat recovery steam<br />

generator modules and power piping spools, involving a<br />

great deal of pipe welding in CMn steel, various creep<br />

resistant grades and stainless steel, including advanced<br />

grades like P91, as well as nickel alloys.<br />

Base materials are cut and bevelled in the semifinishing<br />

hall and are taken to the various manufacturing<br />

halls by separate routes for each project. CNC<br />

plasma equipment is used to cut stainless and high-alloy<br />

pipe and plate and to cut the branch openings in carbon<br />

steel pipes. Various types of oxyfuel cutting equipment,<br />

including CNC, are available for products of all kinds.<br />

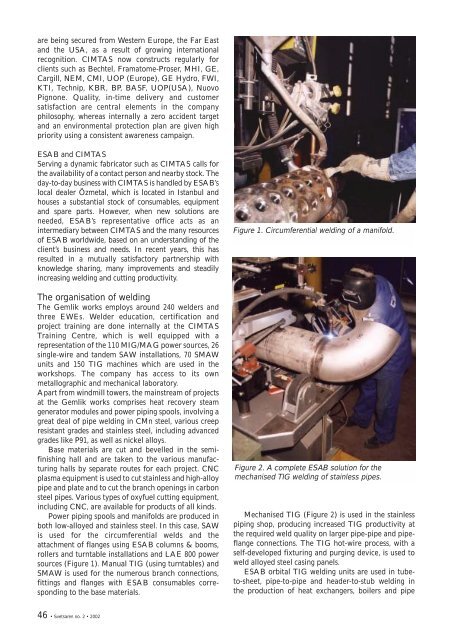

Power piping spools and manifolds are produced in<br />

both low-alloyed and stainless steel. In this case, SAW<br />

is used for the circumferential welds and the<br />

attachment of flanges using ESAB columns & booms,<br />

rollers and turntable installations and LAE 800 power<br />

sources (Figure 1). Manual TIG (using turntables) and<br />

SMAW is used for the numerous branch connections,<br />

fittings and flanges with ESAB consumables corresponding<br />

to the base materials.<br />

Figure 1. Circumferential welding of a manifold.<br />

Figure 2. A complete ESAB solution for the<br />

mechanised TIG welding of stainless pipes.<br />

Mechanised TIG (Figure 2) is used in the stainless<br />

piping shop, producing increased TIG productivity at<br />

the required weld quality on larger pipe-pipe and pipeflange<br />

connections. The TIG hot-wire process, with a<br />

self-developed fixturing and purging device, is used to<br />

weld alloyed steel casing panels.<br />

ESAB orbital TIG welding units are used in tubeto-sheet,<br />

pipe-to-pipe and header-to-stub welding in<br />

the production of heat exchangers, boilers and pipe<br />

46 • <strong>Svetsaren</strong> no. 2 • 2002