May/June 2013 - The ASIA Miner

May/June 2013 - The ASIA Miner

May/June 2013 - The ASIA Miner

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Asian Intelligence<br />

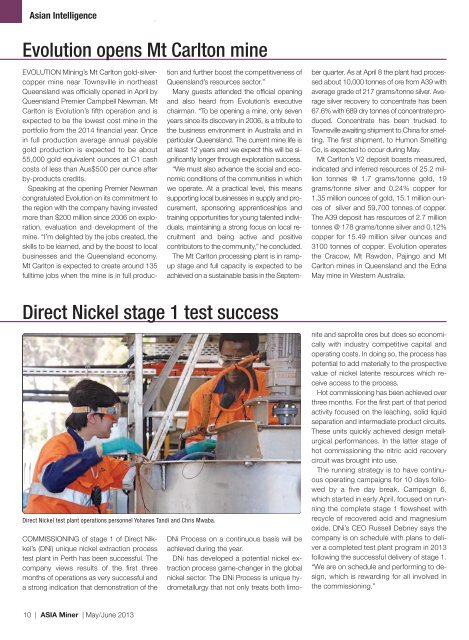

Evolution opens Mt Carlton mine<br />

EVOLUTION Mining’s Mt Carlton gold-silvercopper<br />

mine near Townsville in northeast<br />

Queensland was officially opened in April by<br />

Queensland Premier Campbell Newman. Mt<br />

Carlton is Evolution’s fifth operation and is<br />

expected to be the lowest cost mine in the<br />

portfolio from the 2014 financial year. Once<br />

in full production average annual payable<br />

gold production is expected to be about<br />

55,000 gold equivalent ounces at C1 cash<br />

costs of less than Aus$500 per ounce after<br />

by-products credits.<br />

Speaking at the opening Premier Newman<br />

congratulated Evolution on its commitment to<br />

the region with the company having invested<br />

more than $200 million since 2006 on exploration,<br />

evaluation and development of the<br />

mine. “I’m delighted by the jobs created, the<br />

skills to be learned, and by the boost to local<br />

businesses and the Queensland economy.<br />

Mt Carlton is expected to create around 135<br />

fulltime jobs when the mine is in full production<br />

and further boost the competitiveness of<br />

Queensland’s resources sector.”<br />

Many guests attended the official opening<br />

and also heard from Evolution’s executive<br />

chairman. “To be opening a mine, only seven<br />

years since its discovery in 2006, is a tribute to<br />

the business environment in Australia and in<br />

particular Queensland. <strong>The</strong> current mine life is<br />

at least 12 years and we expect this will be significantly<br />

longer through exploration success.<br />

“We must also advance the social and economic<br />

conditions of the communities in which<br />

we operate. At a practical level, this means<br />

supporting local businesses in supply and procurement,<br />

sponsoring apprenticeships and<br />

training opportunities for young talented individuals,<br />

maintaining a strong focus on local recruitment<br />

and being active and positive<br />

contributors to the community,” he concluded.<br />

<strong>The</strong> Mt Carlton processing plant is in rampup<br />

stage and full capacity is expected to be<br />

achieved on a sustainable basis in the September<br />

quarter. As at April 8 the plant had processed<br />

about 10,000 tonnes of ore from A39 with<br />

average grade of 217 grams/tonne silver. Average<br />

silver recovery to concentrate has been<br />

67.6% with 689 dry tonnes of concentrate produced.<br />

Concentrate has been trucked to<br />

Townsville awaiting shipment to China for smelting.<br />

<strong>The</strong> first shipment, to Humon Smelting<br />

Co, is expected to occur during <strong>May</strong>.<br />

Mt Carlton’s V2 deposit boasts measured,<br />

indicated and inferred resources of 25.2 million<br />

tonnes @ 1.7 grams/tonne gold, 19<br />

grams/tonne silver and 0.24% copper for<br />

1.35 million ounces of gold, 15.1 million ounces<br />

of silver and 59,700 tonnes of copper.<br />

<strong>The</strong> A39 deposit has resources of 2.7 million<br />

tonnes @ 178 grams/tonne silver and 0.12%<br />

copper for 15.49 million silver ounces and<br />

3100 tonnes of copper. Evolution operates<br />

the Cracow, Mt Rawdon, Pajingo and Mt<br />

Carlton mines in Queensland and the Edna<br />

<strong>May</strong> mine in Western Australia.<br />

Direct Nickel stage 1 test success<br />

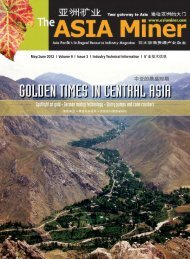

Direct Nickel test plant operations personnel Yohanes Tandi and Chris Mwaba.<br />

COMMISSIONING of stage 1 of Direct Nikkel’s<br />

(DNi) unique nickel extraction process<br />

test plant in Perth has been successful. <strong>The</strong><br />

company views results of the first three<br />

months of operations as very successful and<br />

a strong indication that demonstration of the<br />

DNi Process on a continuous basis will be<br />

achieved during the year.<br />

DNi has developed a potential nickel extraction<br />

process game-changer in the global<br />

nickel sector. <strong>The</strong> DNi Process is unique hydrometallurgy<br />

that not only treats both limonite<br />

and saprolite ores but does so economically<br />

with industry competitive capital and<br />

operating costs. In doing so, the process has<br />

potential to add materially to the prospective<br />

value of nickel laterite resources which receive<br />

access to the process.<br />

Hot commissioning has been achieved over<br />

three months. For the first part of that period<br />

activity focused on the leaching, solid liquid<br />

separation and intermediate product circuits.<br />

<strong>The</strong>se units quickly achieved design metallurgical<br />

performances. In the latter stage of<br />

hot commissioning the nitric acid recovery<br />

circuit was brought into use.<br />

<strong>The</strong> running strategy is to have continuous<br />

operating campaigns for 10 days followed<br />

by a five day break. Campaign 6,<br />

which started in early April, focused on running<br />

the complete stage 1 flowsheet with<br />

recycle of recovered acid and magnesium<br />

oxide. DNi’s CEO Russell Debney says the<br />

company is on schedule with plans to deliver<br />

a completed test plant program in <strong>2013</strong><br />

following the successful delivery of stage 1.<br />

“We are on schedule and performing to design,<br />

which is rewarding for all involved in<br />

the commissioning.”<br />

10 | <strong>ASIA</strong> <strong>Miner</strong> | <strong>May</strong>/<strong>June</strong> <strong>2013</strong>