Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In (10), rk is the coefficient <strong>of</strong> the kth order term in the<br />

polynomial representation <strong>of</strong> R2_ref. SOD selected is less than<br />

the SOD level at the termination <strong>of</strong> discharge. The terminal<br />

SOD chosen in this paper is 0.7. Then the correction term is<br />

i* R ( T)<br />

2<br />

α ( T ) =<br />

(11)<br />

i* R2_ref<br />

From (9)-(11), R2 <strong>of</strong> the internal resistance can be expressed as<br />

n<br />

k<br />

R = α ( T) * r * SOD [ i( t), t]<br />

(12)<br />

2 � k<br />

k = 0<br />

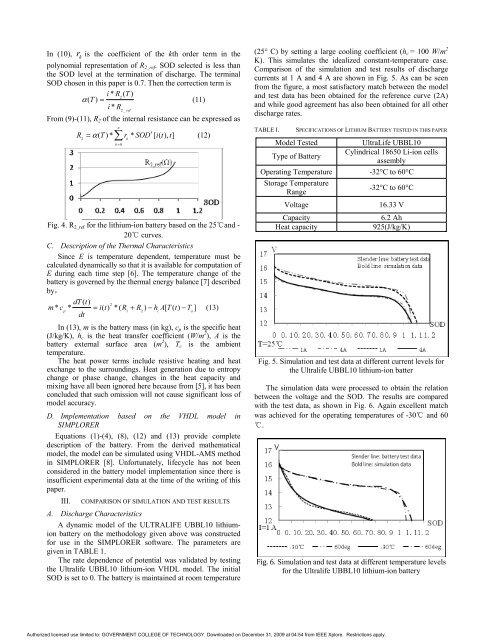

Fig. 4. R2_ref <strong>for</strong> the lithium-ion battery based on the 25�and -<br />

20� curves.<br />

C. Description <strong>of</strong> the Thermal Characteristics<br />

Since E is temperature dependent, temperature must be<br />

calculated dynamically so that it is available <strong>for</strong> computation <strong>of</strong><br />

E during each time step [6]. The temperature change <strong>of</strong> the<br />

battery is governed by the thermal energy balance [7] described<br />

by�<br />

dT () t<br />

2<br />

m* c * = i() t *( R + R ) −h A[ T() t −T<br />

] (13)<br />

p 1 2 c a<br />

dt<br />

In (13), m is the battery mass (in kg), cp is the specific heat<br />

(J/kg/K), hc is the heat transfer coefficient (W/m 2 ), A is the<br />

battery external surface area (m 2 ), Tc is the ambient<br />

temperature.<br />

The heat power terms include resistive heating and heat<br />

exchange to the surroundings. Heat generation due to entropy<br />

change or phase change, changes in the heat capacity and<br />

mixing have all been ignored here because from [5], it has been<br />

concluded that such omission will not cause significant loss <strong>of</strong><br />

model accuracy.<br />

D. Implementation based on the VHDL model in<br />

SIMPLORER<br />

Equations (1)-(4), (8), (12) and (13) provide complete<br />

description <strong>of</strong> the battery. From the derived mathematical<br />

model, the model can be simulated using VHDL-AMS method<br />

in SIMPLORER [8]. Un<strong>for</strong>tunately, lifecycle has not been<br />

considered in the battery model implementation since there is<br />

insufficient experimental data at the time <strong>of</strong> the writing <strong>of</strong> this<br />

paper.<br />

III. COMPARISON OF SIMULATION AND TEST RESULTS<br />

A. Discharge Characteristics<br />

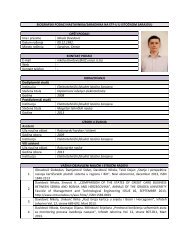

A dynamic model <strong>of</strong> the ULTRALIFE UBBL10 lithiumion<br />

battery on the methodology given above was constructed<br />

<strong>for</strong> use in the SIMPLORER s<strong>of</strong>tware. The parameters are<br />

given in TABLE 1.<br />

The rate dependence <strong>of</strong> potential was validated by testing<br />

the Ultralife UBBL10 lithium-ion VHDL model. The initial<br />

SOD is set to 0. The battery is maintained at room temperature<br />

(25° C) by setting a large cooling coefficient (hc = 100 W/m 2<br />

K). This simulates the idealized constant-temperature case.<br />

Comparison <strong>of</strong> the simulation and test results <strong>of</strong> discharge<br />

currents at 1 A and 4 A are shown in Fig. 5. As can be seen<br />

from the figure, a most satisfactory match between the model<br />

and test data has been obtained <strong>for</strong> the reference curve (2A)<br />

and while good agreement has also been obtained <strong>for</strong> all other<br />

discharge rates.<br />

TABLE I. SPECIFICATIONS OF LITHIUM BATTERY TESTED IN THIS PAPER<br />

Model Tested UltraLife UBBL10<br />

Type <strong>of</strong> <strong>Battery</strong><br />

Cylindrical 18650 Li-ion cells<br />

assembly<br />

Operating Temperature -32°C to 60°C<br />

<strong>Storage</strong> Temperature<br />

Range<br />

-32°C to 60°C<br />

Voltage 16.33 V<br />

Capacity 6.2 Ah<br />

Heat capacity 925(J/kg/K)<br />

Fig. 5. <strong>Simulation</strong> and test data at different current levels <strong>for</strong><br />

the Ultralife UBBL10 lithium-ion batter<br />

The simulation data were processed to obtain the relation<br />

between the voltage and the SOD. The results are compared<br />

with the test data, as shown in Fig. 6. Again excellent match<br />

was achieved <strong>for</strong> the operating temperatures <strong>of</strong> -30� and 60<br />

�.<br />

������� <strong>Simulation</strong> and test data at different temperature levels<br />

<strong>for</strong> the Ultralife UBBL10 lithium-ion battery<br />

Authorized licensed use limited to: GOVERNMENT COLLEGE OF TECHNOLOGY. Downloaded on December 31, 2009 at 04:54 from IEEE Xplore. Restrictions apply.