Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Modeling of Lithium-Ion Battery for Energy Storage System Simulation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

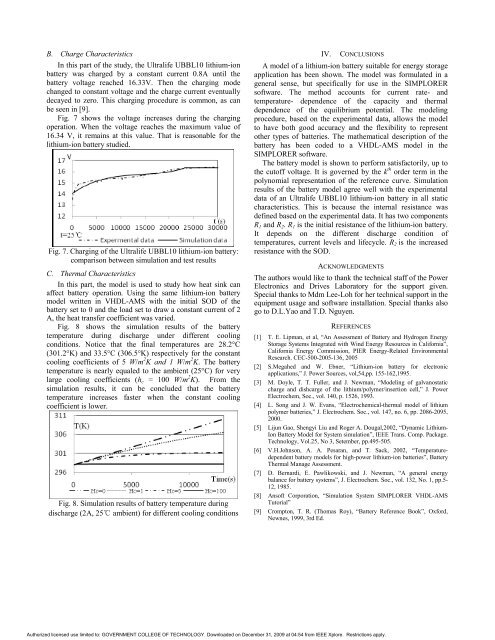

B. Charge Characteristics<br />

In this part <strong>of</strong> the study, the Ultralife UBBL10 lithium-ion<br />

battery was charged by a constant current 0.8A until the<br />

battery voltage reached 16.33V. Then the charging mode<br />

changed to constant voltage and the charge current eventually<br />

decayed to zero. This charging procedure is common, as can<br />

be seen in [9].<br />

Fig. 7 shows the voltage increases during the charging<br />

operation. When the voltage reaches the maximum value <strong>of</strong><br />

16.34 V, it remains at this value. That is reasonable <strong>for</strong> the<br />

lithium-ion battery studied.<br />

Fig. 7. Charging <strong>of</strong> the Ultralife UBBL10 lithium-ion battery:<br />

comparison between simulation and test results<br />

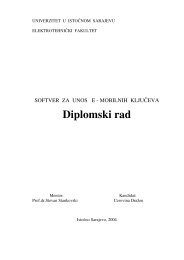

C. Thermal Characteristics<br />

In this part, the model is used to study how heat sink can<br />

affect battery operation. Using the same lithium-ion battery<br />

model written in VHDL-AMS with the initial SOD <strong>of</strong> the<br />

battery set to 0 and the load set to draw a constant current <strong>of</strong> 2<br />

A, the heat transfer coefficient was varied.<br />

Fig. 8 shows the simulation results <strong>of</strong> the battery<br />

temperature during discharge under different cooling<br />

conditions. Notice that the final temperatures are 28.2°C<br />

(301.2°K) and 33.5°C (306.5°K) respectively <strong>for</strong> the constant<br />

cooling coefficients <strong>of</strong> 5 W/m 2 K and 1 W/m 2 K. The battery<br />

temperature is nearly equaled to the ambient (25°C) <strong>for</strong> very<br />

large cooling coefficients (hc = 100 W/m 2 K). From the<br />

simulation results, it can be concluded that the battery<br />

temperature increases faster when the constant cooling<br />

coefficient is lower.<br />

Fig. 8. <strong>Simulation</strong> results <strong>of</strong> battery temperature during<br />

discharge (2A, 25� ambient) <strong>for</strong> different cooling conditions<br />

IV. CONCLUSIONS<br />

A model <strong>of</strong> a lithium-ion battery suitable <strong>for</strong> energy storage<br />

application has been shown. The model was <strong>for</strong>mulated in a<br />

general sense, but specifically <strong>for</strong> use in the SIMPLORER<br />

s<strong>of</strong>tware. The method accounts <strong>for</strong> current rate- and<br />

temperature- dependence <strong>of</strong> the capacity and thermal<br />

dependence <strong>of</strong> the equilibrium potential. The modeling<br />

procedure, based on the experimental data, allows the model<br />

to have both good accuracy and the flexibility to represent<br />

other types <strong>of</strong> batteries. The mathematical description <strong>of</strong> the<br />

battery has been coded to a VHDL-AMS model in the<br />

SIMPLORER s<strong>of</strong>tware.<br />

The battery model is shown to per<strong>for</strong>m satisfactorily, up to<br />

the cut<strong>of</strong>f voltage. It is governed by the k th order term in the<br />

polynomial representation <strong>of</strong> the reference curve. <strong>Simulation</strong><br />

results <strong>of</strong> the battery model agree well with the experimental<br />

data <strong>of</strong> an Ultralife UBBL10 lithium-ion battery in all static<br />

characteristics. This is because the internal resistance was<br />

defined based on the experimental data. It has two components<br />

R1 and R2. R1 is the initial resistance <strong>of</strong> the lithium-ion battery.<br />

It depends on the different discharge condition <strong>of</strong><br />

temperatures, current levels and lifecycle. R2 is the increased<br />

resistance with the SOD.<br />

ACKNOWLEDGMENTS<br />

The authors would like to thank the technical staff <strong>of</strong> the Power<br />

Electronics and Drives Laboratory <strong>for</strong> the support given.<br />

Special thanks to Mdm Lee-Loh <strong>for</strong> her technical support in the<br />

equipment usage and s<strong>of</strong>tware installation. Special thanks also<br />

go to D.L.Yao and T.D. Nguyen.<br />

REFERENCES<br />

[1] T. E. Lipman, et al, “An Assessment <strong>of</strong> <strong>Battery</strong> and Hydrogen <strong>Energy</strong><br />

<strong>Storage</strong> <strong>System</strong>s Integrated with Wind <strong>Energy</strong> Resources in Cali<strong>for</strong>nia”,<br />

Cali<strong>for</strong>nia <strong>Energy</strong> Commission, PIER <strong>Energy</strong>-Related Environmental<br />

Research. CEC-500-2005-136, 2005<br />

[2] S.Megahed and W. Ebner, “<strong>Lithium</strong>-ion battery <strong>for</strong> electronic<br />

applications,” J. Power Sources, vol,54,pp. 155-162,1995.<br />

[3] M. Doyle, T. T. Fuller, and J. Newman, “<strong>Modeling</strong> <strong>of</strong> galvanostatic<br />

charge and dishcarge <strong>of</strong> the lithium/polymer/insertion cell,” J. Power<br />

Electrochem, Soc., vol. 140, p. 1526, 1993.<br />

[4] L. Song and J. W. Evans, “Electrochemical-thermal model <strong>of</strong> lithium<br />

polymer batteries,” J. Electrochem. Soc., vol. 147, no. 6, pp. 2086-2095,<br />

2000.<br />

[5] Lijun Gao, Shengyi Liu and Roger A. Dougal,2002, “Dynamic <strong>Lithium</strong>-<br />

<strong>Ion</strong> <strong>Battery</strong> Model <strong>for</strong> <strong>System</strong> simulation”, IEEE Trans. Comp. Package.<br />

Technology, Vol.25, No 3, Setember, pp.495-505.<br />

[6] V.H.Johnson, A. A. Pesaran, and T. Sack, 2002, “Temperaturedependent<br />

battery models <strong>for</strong> high-power lithium-ion batteries”, <strong>Battery</strong><br />

Thermal Manage Assessment.<br />

[7] D. Bernardi, E. Pawlikowski, and J. Newman, “A general energy<br />

balance <strong>for</strong> battery systems”, J. Electrochem. Soc., vol. 132, No. 1, pp.5-<br />

12, 1985.<br />

[8] Ans<strong>of</strong>t Corporation, “<strong>Simulation</strong> <strong>System</strong> SIMPLORER VHDL-AMS<br />

Tutorial”<br />

[9] Crompton, T. R. (Thomas Roy), “<strong>Battery</strong> Reference Book”, Ox<strong>for</strong>d,<br />

Newnes, 1999, 3rd Ed.<br />

Authorized licensed use limited to: GOVERNMENT COLLEGE OF TECHNOLOGY. Downloaded on December 31, 2009 at 04:54 from IEEE Xplore. Restrictions apply.